Kumba Resources has a three-fold strategic priority that involves the optimisation of existing operations, optimising its market positioning in the short and medium term and ensuring sustainable growth in the longer term.

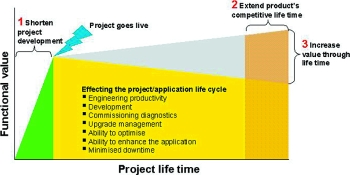

The optimisation strategy includes maximising outputs through greater operational efficiencies and expansion programmes of existing operations. Value-engineering and continuous improvement interventions have already resulted in substantial increases in throughput of up to 30%, with a concurrent reduction in manpower of 17% over the past four years. Part of this on-going initiative has involved the recent adoption of Wonderware's ArchestrA industrial automation framework to assist with the development of standards and reduction in project engineering costs.

Kumba Resources appointed system integrator GijimaAst to investigate the implementation and deployment of a solution at its Sishen, Grootgeluk and Leeuwpan plants that would help the company achieve its optimisation strategy. The investigation led to the Kumba Resources Phase II Automation Software Standardisation project also referred to as the 'Leeuwpan Drum Plant ArchestrA Pilot project'.

The Leeuwpan mine in Mpumalanga produces Direct Reduction Coal (DRI) and coal for pulverised injection to meet the growing demand of local steel works. Leeuwpan also supplies power station coal that is sold to ESKOM, municipal power stations, local industrial users and which is also exported.

As part of its group-wide business improvement programme, Kumba Resources has identified a need to reduce the total cost of ownership and increase the return on investment within its automation environment. The key factors that would help achieve this include minimising costs, increasing revenues, reducing development and integration costs and also reducing ongoing maintenance, training and support costs. The single most important contributor towards achieving all this was identified as standardisation. Standardisation would reduce the number of variances within the automation environment, thereby avoiding the re-invention of wheels and approaches for every project. Whatever solution was chosen had to be independent of existing scada/HMI systems yet it should protect Kumba's investment in such resources by allowing them all to contribute to the company's business objectives.

"In order for Kumba to move ahead," says Flip Schutte, senior technology architect at Kumba Resources, "we formulated the Shared Services Model that highlighted the need for standardisation and simplification of our operating procedures which would all lead to reduced total cost of ownership. We believe that this can be achieved through a reduction in maintenance, fault-finding and engineering costs. Automation projects are only means to various ends. They are not supposed to consume vast financial resources or be unwieldy and costly to maintain. We believe that ArchestrA will make it easier and less costly to expand our automation capabilities as and when required such as the proposed new developments at Sishen. ArchestrA will also help us initiate proper MES components in our works."

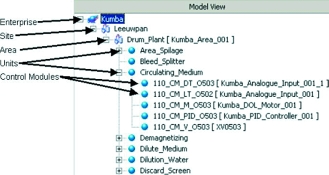

Schutte says that once the company's standards are in place, contractors bidding for work will have to conform to these standards in order to maintain consistency throughout the organisation. "Phase 1 of the project consisted of GijimaAst determining the maturity of the existing Kumba Resources Grootgeluk and Sishen sites in order to use these as a basis for what would eventually become the Kumba Resources standard for the company's plant and automation devices as well as PLCs," says Petrus Klopper, portfolio manager at GijimaAst.

Based on the results of Phase 1, it was decided that the existing Sishen standards as well as a combination of best practices would be used for Phase 2 of the project while bearing in mind the different nature of the plants (ie iron ore at Sishen and coal at Grootgeluk and Leeuwpan). Another consideration was that Sishen uses a different scada system to the InTouch solution in use at Grootgeluk and Leeuwpan.

'The signs from the off-line pilot project for the drum plant at Leeuwpan are very encouraging,' says Schutte. 'Management has been impressed by the final acceptance tests done at the plant and we have plans to do the same for the JIG plant. The reason we are not yet live at the drum plant is because we want to upgrade the existing PLCs and we will start this at the new JIG plant.'

Kumba is looking forward to a standardised and unified approach to their automation needs throughout their plants that will lead to significantly lower cost of ownership through more efficient project implementation and maintenance, while capitalising on their existing assets.

Project summary:

* Client: Kumba Resources (Leeuwpan).

* Project goal: To reduce the total cost of ownership of the various control systems within the Kumba Resources Group.

* How to get there: Select a solution that would reduce development and integration costs as well as ongoing maintenance, training and support costs.

* Selected solutions: Wonderware's ArchestrA and its Industrial Application Server (IAS).

* Derived benefits: Working standards were documented that can be used in future tenders and a centre of excellence was established that can be used by the rest of the Kumba Resources group. Ultimately, significant savings in development and integration times as well as a reduction in support costs were experienced. Another and not-insignificant benefit, is that there is now a structure to which value can be added.

* System Integrator: AST Group.

About Kumba Resources coal

Kumba Resources coal assets are housed in Kumba Coal, a wholly owned subsidiary operating three collieries, Grootegeluk, Tshikondeni and Leeuwpan. Kumba coal produces 18,5 million tons of thermal and coking coal for the domestic and export markets.

75% of Kumba Coal's total coal production is consumed by ESKOM, South Africa's electric power utility company. The remaining production is supplied to Ispat -Iscor's steel operations and a variety of local and international clients.

About Kumba Resources iron ore

Kumba Resources owns a large proportion of the known lump ore reserves in the world, capable of yielding more than a billion tons of ore. The ore is mined in South Africa at the Thabazimbi Iron Ore Mine in Limpopo Province and at the Sishen Iron Ore Mine, one of the world's largest iron ore mines, in the Northern Cape Province. Thabazimbi produces for the domestic market while Sishen exports most of its production via the west coast port of Saldanha.

The company currently produces 30,5 million tons of iron ore per annum. About 21,4 million tons is consumed by the international market through long term contractual agreements with more than 35 major steel producers in 16 countries around the world. The South African steel market consumes the remaining 9,1 million tons.

About ArchestrA

ArchestrATM technology is a comprehensive plant automation and information architecture designed from the outset to extend the life of legacy systems by being developed from the ground up using the latest software technologies like Microsoft.NET. Offerings built upon this architecture empower decision-makers to achieve their business goals, without abandoning prior investments in automation systems, production processes or intellectual property. In the ArchestrA environment, software applications can be rapidly assembled rather than programmed. New applications also can be created simply through the re-assembly of existing applications.

ArchestrATM allows for the standardised modelling of templates for plant objects and their automatic deployment after changes. These templates can be changed at any time to include attributes for the collection of additional information without the necessity to change any software code. This means that end-users can grow their applications at will and 'after the fact' to cope with changing circumstances.

For more information contact Justin Tweedie, Futuristix, 0861WONDER, [email protected]

Petrus Klopper, GijimaAst, 012 675 5000, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved