Developed on the back of 35+ years of experience in the process automation field, Omniflex offers a truly home grown PLC solution for industry. With many blue chip users of the Maxiflex technology both locally and internationally Omniflex can offer true First World solutions in the automation field. While it is known that telemetry, data acquisition, alarm and events management are core business for Omniflex, the jump to process automation was a small one to take for the Maxiflex Hardware platform, already field proven internationally and locally in many mission critical applications. The Maxiflex Process automation suite provides a fully integrated suite of application solutions for industrial applications with many cost saving benefits.

Omniflex process automation suite

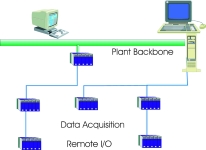

The process automation suite provides an easy to use, cost effective and expandable process control system. Integrated control software using IEC 61131 standard software languages, data acquisition, telemetry, remote I/O systems capability and the ability to incorporate and integrate existing hardware systems makes this Omniflex solution easy to integrate in any application.

Modular: 'Buy only what you need'

The Process Automation Suite is a modular system comprising the following elements:

1. IEC 61131 Control Strategy Programming Environment with a Windows-based PC Workbench.

2. The Maxiflex process automation controller series and associated I/O hardware platform.

3. The Maxiflex flexible networking environment and networking hierarchy.

4. The Maxiflex remote I/O systems capability.

5. Under the bonnet data acquisition and telemetry functionality.

6. Integrated alarm and events services (date and time stamp queue).

7. OPC servers for a variety of Network Protocols including Ethernet.

IEC 61131 workbenches control strategy programming

The workbenches are price structured according to I/O capability, with an unlimited range beginning at 32 I/O. This allows the user to pay according to the scale of the maximum size system. The workbench is a once off cost and can be used on multiple CPUs. Users simply buy a workbench sized to cover the maximum I/O on a single CPU and apply it everywhere. The workbenches are Windows operating systems based.

Omniflex adopted IEC standard programming because of the international trends in PLC programming environments. The user can use any one of six standard programming languages for control strategies.

* Ladder.

* Function block.

* Flow chart.

* Sequential function chart.

* Structured text.

* Instruction list.

Maxiflex process automation controllers

The PAC is based on the Maxiflex P3 CPU platform. The Maxiflex Process Automation Controllers (PAC) run the IEC 61131 Control Applications and are available in a number of variants to suit Network Preferences: Ethernet (with Modbus TCP), Ethernet (Conet), Modbus, Conet/c.

Conet/m (Packet Radio Protocol)

This provides a flexible network environment satisfying most networked applications and plant topologies. Process control applications invariably involve the following functionality for effective implementation:

* Interlock controls.

* Analog signal processing.

* Control algorithms - including PID with Auto-tune.

* Network communications.

* Remote I/O applications.

* Redundant controllers and networks.

* Alarm and events monitoring.

* Date and time stamping at source for sequence-of-events monitoring.

* The ability to service Windows-based scada systems.

All of which the PAC delivers with ease.

Remote I/O systems

Maxiflex is endowed with the ability to implement hierarchical networks with transparent linking from lowest to highest level and vice versa. The ability to configure seamless routing from Ethernet to a fieldbus network like Conet or even a packet radio system provides system integration tools few can compete with. Redundant communications can also be simply implemented using modular applications. Field I/O can be collected easily with analog inputs such temperature being accepted directly along with a wide variety of other analog and digital inputs and outputs.

Integrating third party devices

Maxiflex has direct serial inputs for which protocols can be developed to integrate other devices in the Omniflex Remote I/O system. Devices such as Analytical Instrumentation can be integrated into the system. Device protocols are developed and downloaded to Network Interface Modules that integrate the foreign device into the Maxiflex Network System.

Flexible integrated applications and services

Built-in special features

The Process Automation Suite embraces all these elements providing a flexible and an extremely adaptable platform. Many 'under the bonnet' features like date and time stamped events, telemetry and auto I/O scanning are standard offerings.

Date and time stamp

This is a service available with Conet Protocol applications that will provide an event stream (ie, each input change of state and the time and date it happened) from the front-end device. These events can then be collected and analysed on a scada system with the events in chronological order. Pre- and post-event analysis can then be reviewed from the scada database. This service differs from the scada date and time stamp in that it is free from network propagation errors that can affect time stamping done on the scada PC.

Data acquisition

The Maxilfex CPUs and PACs have the ability to be used as program-less Data Acquisition devices as they automatically read their I/O without an application program resident.

'Auto I/O scanning'

The status of the inputs and outputs are reflected in a Data Interchange Table (DIT) which is accessible via the networks. Any other device on the network including scada or DCS has access to read those DIT Registers. This applies even when the CPU is running an application program to execute some other function.

Telemetry

A range of telemetry enabled CPUs, the T series provide powerful remote I/O capabilities also with the user writing programs to transfer data from one node to another. Network services such as subscriptions and datagrams are used to configure a telemetry application. Data can be subscribed across a network by simply configuring some DIT registers. This service can be run on cyclic basis (time interval) or on change of state.

OPC servers

The link to PC-based scada HMIs is implemented through OPC servers for Windows operating systems-based scada packages. The OPC server facilitates the delivery of data to the OPC clients running on the Windows operating system and allows the control of field outputs. The OPC server uses a tag based I/O system, which is easily exchanged with the scada tag configuration.

Configuration and diagnostic tools

Windows-based configuration and diagnostic tools allow the user to configure and interrogate any other node on the network from any point on the network or networks.

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved