The ABB AO2000 CGA (continuous gas analyser) is used to measure low concentrations of gas components in industrial processes and environmental monitoring systems. The units are modular and can be configured to suit the customers' needs. A multitude of gas parameters and other related variables can be measured continuously and simultaneously by the CGA. Typical applications require the units to be situated in remote locations, where fixed line communication is either not practical or is too costly to install.

Many customers rely on the expertise and experience of ABB personnel in using and/or maintaining the sophisticated CGA systems. On-site technical staff often do not understand the reasons for an alarm condition, sometimes not knowing when an alarm condition has occurred. Historical data and trending information often needs to be imported into other systems in order to be analysed. Due to the physical location of many of the units, access to the front panel is not always an easy task.

The following alternatives are available:

* Monitoring the analysers with plant DCS systems, which involves running cables to the remote analysers.

* Calling out ABB specialised servicemen, which is costly and time consuming and may even contribute to process downtime.

* Specific training of on-site technicians - which is likely not core to their industry.

Beyond Wireless Technology solution

Beyond Wireless Technology was selected to provide an end-to-end solution. This was based on their levels of expertise in matching technology to the requirements, their experience in wireless communication, and their ability to identify and match the commercials to the solution resulting in a sound business case. Considering the physical location of the units, data communication costs, and the remote access requirements, it was an obvious choice to develop a GSM based solution.

Solution functionality

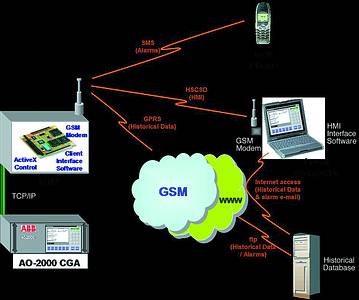

The solution enables wireless remote monitoring and control of the analysers using various bearers on the GSM network. A remote terminal unit (RTU) is used as the physical interface to the CGA, and connects via an Ethernet cable. It has a GSM modem built-in for communication. The RTU is programmed with intelligence to automatically identify the analyser serial number, components (main and auxiliary), and various other parameters as soon as it is connected to an analyser. This information is stored in data packs on its own memory as well as the Internet database.

There are three functional components of the system:

* Remote HMI interface

The remote HMI (human machine interface) is a realtime control mechanism that graphically mimics the actual CGA display, allowing remote access to all CGA front panel functions. Communication is achieved using HSCSD (high speed circuit switched data) over the GSM network. The CGA is dialled into from anywhere where there is GSM coverage. A computer and GSM modem is required for this.

* Web-based historical database

Historical data is captured in realtime (24 hours a day) on the RTU. This is done at the required sample frequency and is transmitted to a database on a hosted server. This information is published on an Internet site that is available only with a registered Username and Password. All available components on a particular CGA are measured and captured including primary gas sampling, sample conditioning and gas analysis. Other process signals such as pressure, flow, temperature and status signals are also captured. The data may be presented in a table, graphically or in standard report format indicating minimum, maximum and average values over requested time intervals.

* Alarms and alerts via SMS/e-mail

The system can be configured to send alerts and alarms to either an e-mail address and/or via SMS to a cellphone as soon as they occur. Escalation rules can be applied where SMSs are sent to three different levels in the event of alarm conditions not being cleared within a stipulated time period.

The benefits

* Immediate alerts to alarm conditions.

* World-wide on-line access to all sites (historical data).

* Allows for predictive maintenance thus reducing downtime and costly equipment failures.

* Enables qualified personnel to access CGAs without having to physically travel to the remote sites.

* Reduces process downtime due to speedy access by specialised personnel.

* Low set-up and installation cost.

About Beyond Wireless Technology

Remote asset management technologies benefit companies by providing realtime, world class, cost effective solutions. Beyond Wireless Technology specialises in machine-to-machine (M2M) solutions and addresses the challenges that clients are faced with when applying these technologies. Beyond provides objective advice and will recommend only the most appropriate solutions that will provide quantifiable business benefits. This analysis is performed with the client, ensuring that the solution fits the specific business requirements.

Clients are not expected to purchase and develop complex proprietary hardware and applications from disparate vendors, nor are they required to invest in infrastructure or skills that are non-core to their business. Beyond will facilitate and manage the entire project from concept to full-scale deployment and will support the entire solution on an ongoing basis.

For more information contact ABB Analytical department, 011 236 7000 or Dion Rachelson, Beyond Wireless Technology, 083 708 9838.

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved