Reviewer details

Name: Johnny Welman

Position/Designation: Scada systems technician

Company: Sasol Gas

Telephone: 011 617 8254

E-mail: [email protected]

Product details

Vendor: Adroit Technologies

Product name and version: Adroit 5.0

Telephone: 011 658 8100

E-mail: [email protected]

URL: www.adroit.co.za

General

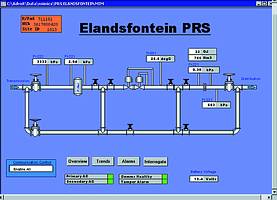

Q: What industry (eg, mining, food and beverage, automotive etc) is the scada being applied in?

A: Pipeline gas - methane, hydrogen and natural gas.

Q: Describe the application briefly giving a description of any existing control systems, any previous scada system that was in place etc. If relevant describe the switchover from the previous system?

A: Remote monitoring of pipeline gas distributed over a very wide area. Pressures, flows and temperatures are monitored. User interfaces are available at the remote plants, which connect to the server over the LAN network. Insys was the previous scada system, which was not configurable by the user. All modifications had to be done by the vendor.

Q: Who did the system integration?

A: Alcom Motamo Systems.

Q: How is the after-sales support handled (eg, remote-dial-up, e-mail, Internet access etc)?

A: Support issues are handled by e-mail, telephone and on-site visits.

Q: What sort of licensing agreement is used on this particular system? Does one licence cover all modules, or can the user only buy those modules that he wishes to use?

A: Due to the wide area network we have various systems. Each remote site has a licence with a number of assigned login users.

System architecture

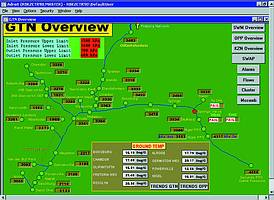

Q: How many tag points/I/O does the installation have? Analog? Digital? Maximum possible?

A: Our largest licence is for 2500 scan points. Currently only 1200 are being used: - 950 analogs and 250 digitals. Should there be a need for expansion the licence can be upgraded to an unlimited number of tag points.

Q: What operating system is the scada running on (eg, Windows NT, Unix etc)?

A: Windows 2000/XP.

Q: What impressed you most about the architecture? Open standards, wide range of drivers, the ability to upgrade, etc? Please elaborate.

A: A very extensive range of available drivers forms an integral part of the system. It is hassle free and really easy to upgrade to the next version or increase the tag size, one does not have to start from the beginning.

Q: Is the system integrated onto an intranet or the Internet? If so, does the configuration allow simple remote monitoring, or is it configured to allow full remote control? If not, what level of intranet/Internet control does the scada allow for future use?

A: We publish Web pages on our website as some information needs to be available to the public.

Q: What sort of redundancy is built into the system?

A: Daily backups are done as well as a duplicate system at the main control room. An Adroit Hot-Standby, Active Cluster is implemented due to the critical nature of the project.

Graphics

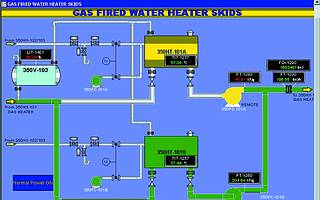

Q: Describe the graphics development process - eg, did you use standard library images, or did you have to draw images from scratch?

A: There is a huge library of images that is included with the application; these were used to draw images corresponding to the old scada system very quickly and easily.

Q: How would you describe the library of graphic images?

A: A large variety available - well covered.

Q: Did you use any 'special' images (eg, embedded video clips, photographs, 3D images etc)?

A: No, would like to use as-built photos, but because of network restraints it is not implemented.

Compatibility

Q: Does the scada allow for the user to create scripts to perform specific tasks? Describe any specific scripts that were written for this project.

A: Yes, an Excel report is run to export certain tags in table form on a weekly basis and by using a WAN Server and Wan Client configuration data can be sent to and from other servers.

Management reporting

Q: Is a trending and historical data reporting system included? Please elaborate.

A: Yes, data are logged and stored for 100 days on the server. Features like bookmarkings and multicolour graphs are very useful.

Q: Is a management reporting system included in the package?

A: No.

Q: Is the system integrated into a manufacturing execution system?

A: No.

Q: Is the scada system integrated into a management reporting or control system (eg, SAP, Baan)?

A: No, not at present.

Conclusion

Q: What impressed you the most about the system?

A: It is a stable and reliable system. It is a local product with great after sales service.

Q: What was the predominant feature (or features) that made you decide to employ this scada, rather than another (ie, ease of use, support from the vendor, upgrade path, redundancy features etc)?

A: Initial cost, support from vendor, quick and easy changes whilst on-line.

© Technews Publishing (Pty) Ltd | All Rights Reserved