Sheba Gold Mine has installed Adroit's advanced 32-bit, open automation supervisory control and data acquisition (scada) software to maximise the effectiveness of the processes at the mine. Efficiency improvements included a reduction in downtime hours and also the complete visualisation of the Sheba plant and underground water monitoring operations at the production site itself and also at nearby Fairview mine.

Located approximately 35 km from Barberton in Mpumalanga province, Sheba is one of the richest visible gold mines in the world with lode gold ore bodies that are believed by some to have been formed about 3,1 billion years ago. The position and shape of these rich lodes are structurally controlled and the gold is not only rich, but it is also amongst the oldest on the planet.

Bacterial oxidation, or Bioxâ as it is commonly known, is the technique used to assist in leaching the gold from the rock. The Bioxâ technique was developed at Fairview mine (located 30 kms from Sheba), under license to Biomin (Goldfields) where the rock is processed and the gold extracted. Bioxâ is now being exported around the world to countries such as Australia, Ghana and Chili and others with a rich mining heritage.

The 120 year old Sheba mine has two Adroit Version 5 scada systems running on a Telemechanique system and 17 Modicon programmable logistics controllers (PLCs), 14 below ground and three above.

The first scada system monitors the above ground-processing plant while the second monitors the underground operations and pumping stations. Eugene Reyneke, instrumentation technician for Sheba Mine was responsible for the installation of the Adroit system as well as the programming of the PLCs, "We used separate Adroit scada systems above and below ground because operation hours are different and control philosophy and monitoring are different. Plant monitoring has 24 hours a day supervision while the underground operation only gives an alarm when generated after hours."

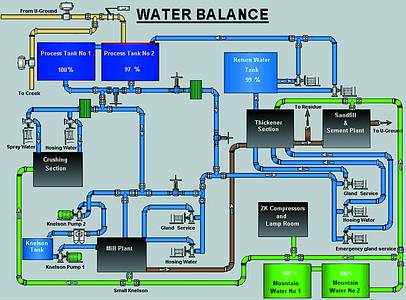

Monitored underground operations consist of two or three sets of pumps (depending on the distance between levels) that control the dam levels. The Adroit scada is currently monitoring nine of the 35 levels. Excess water from the rock seepage is pumped upwards from level to level to until it reaches the surface where it is used in the plant or pumped into the slimes dams. Using the Adroit system, the mine can stop/start the underground pumps on high and low level automatically, oversee the winders, check the running hours of the pumps, monitor the level of the dams and monitor pump trips through the scada's alarming system, to avoid flooding that would endanger lives and halt production. Due to the importance of the pumps, each set of pumps has a standby. It also controls and monitors the settler that cleans the water for re-use in mining operations.

The Adroit scada provides 24-hour monitoring for the underground operations. The Adroit alarming feature has been configured to notify, monitor dam levels at night, and an alarm is sent to the guards at the gate in the form of a hardwired buzzer and light indication. In response, the guard must deactivate the buzzer and telephone the person on standby. Concurrently, the Adroit scada is connected to a modem that automatically dials the foreman on duty via his cellphone, notifying him of the problem and its physical location via SMS. He in turn can contact the necessary persons if need be, such as electricians.

The underground operations levels have each been fitted with Modicon Micro PLCs running on a daisy chain system. Each PLC is connected via a modem and ultimately to an Adroit scada system located at the shaft on the surface.

Pawel Pietak, Adroit's support manager expands on the communication system that they developed for Sheba, "High frequency data transfer was hampered by the mountainous region. We installed a WAN link using a slow radio network. This meant we could avoid the expense and difficulties of trying to install cable over the rocky terrain. Information from the shaft is relayed by receivers to the regular LAN from where it uses normal communication cable."

Using the WAN link, information transfer is virtually instantaneous, with mimics being updated every 10-15 seconds. This allows the mine operators and managers to keep a finger on the pulse of the operations from remote locations, including Fairview mine to which it is connected via the Ethernet. Now the complete underground system at Sheba mine can be remotely monitored at Fairview.

A separate Adroit system is located approximately 500 m from the one at the shaft and is employed at the surface operations and processing plant where the crushing, milling and concentration takes place. This Adroit provides a visual overview of the plant for monitoring as well as certain aspects of control to make the processes as efficient as possible from the underground tips to when the processed concentrate is loaded onto trucks for transportation.

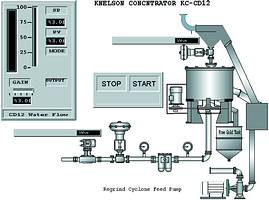

The shaft rock is processed using a jaw crusher, a Simon's crusher where it is reduced to 10-12 mm and it is finally sent to a ball mill where it is milled to 80%-75 µ. Two Knelson concentrators are used to remove the free gold fraction from the ore. The Knelson, which operates on a batch basis, is controlled by the PLC and Adroit scada system. The gold concentrate is floated off, and the concentrate is pumped into a tank from where it is loaded into trucks and transported to Fairview where the gold is leached using the Bioxâ process.

Machine hours and feed rates to the crushers are monitored and calculated, flotation levels, feed rates to the ball mill, thickener density and flow rate to the slime's dams are all monitored by the Adroit above ground scada system.

Graphics were predominantly drawn from the Adroit wizards and supplemented with digital photographs of the underground compressors at Fairview to give an indication of variables such as the water in/out flow temperatures and the oil pressure and operational status of the motors. The Adroit trending function is used to monitor the feeding rates for the ball mill and crushers, as well as the machine hours for purposes of preventative maintenance.

The mine has a Technology Agreement with Adroit that provides support and lays out the service level agreement between the two companies. Reyneke comments, "Whenever I want to create something out of the ordinary with the system, Adroit send out some of their experts and we brainstorm about how to get it done. Their support is always very efficient."

Reyneke uses the Adroit system for some of the report generation on the plant section such as calculating tonnages from the belts weighers and the tonnages that go to the mill, which he draws into an Excel spreadsheet to provide him with an indication of productivity from which he can draw graphs. Reyneke plans to extend the use of the Adroit reporting feature in the future.

For more information contact Dave Wibberly, Adroit Technologies, 011 781 3511, [email protected]

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved