Over the last 20 years Omniflex has designed and delivered products and systems for the nuclear industry, specialising in alarm annunciators, alarm/event management systems, multiplexers and radiological surveillance systems. As part of British Nuclear Fuel's standard ILW design standards, Omniflex was chosen to supply both radiological surveillance and alarm/event management systems.

A number of new interface modules have been developed for the well-proven Maxiflex I/O system to provide interfaces to any of the existing or new ranges of Harwell or Lab Impex Alpha, Beta and Gamma radiation monitors. The ILW design also includes the supply of an independent alarm management system, which is designed to provide realtime alarm/event monitoring. Omniflex Maxilarm and Omni 4000 systems were chosen to provide this critical monitoring and logging.

The Maxiflex system

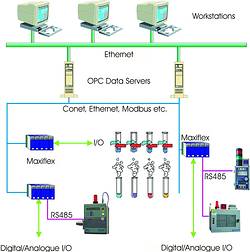

The Maxiflex I/O system is designed to provide a cost effective and flexible means of interfacing any radiation monitor to the building or site-wide scada system. Maxiflex is modular in design and can accommodate any type of digital or analog signal, together with distributed intelligent communications modules. The intelligent radiation monitor interface module makes it a suitable system to distribute around the building or site. Maxiflex has a powerful communications infrastructure supporting Conet Fieldbus internetworking technology. A mix of communications media may be applied to suit the site including Conet/c (any grade of 2 core cable up to 10 km without the need for repeaters), Modbus, Ethernet, PSTN and radio for those wireless applications. This range of specially developed radiological monitor interfaces allow existing infrastructure to be reliably and cost effectively networked.

Harwell radiation monitors 3230 and 3280 and AB96, G64, ICAM

These Alpha/Beta monitors provide a RS485 network output, for which a Harwell NIM (network interface module) model M1588A was developed. This module will enable up to 32 monitors to be inter-connected on the same RS485 network. Up to 15 of these modules can be fitted to one Maxiflex system with no limit to the number of Maxiflex systems that can be interconnected.

Lab Impex radiation monitors - CMS 2000

These Alpha/Beta/Gamma monitors provide a RS485 network output, for which a LabImpex NIM (network interface module) M1585A was developed. This module will enable up to 32 monitors to be interconnected on the same RS485 network. Up to 15 of these modules can be fitted to one Maxiflex system - again, with no limit to the number of Maxiflex systems that can be interconnected.

Other radiation monitoring equipment

Omniflex has in-depth expertise and experience in the development of custom protocols and interfaces for third party equipment. It is likely that the company has already implemented a protocol similar to your next special application, and can assist with a cost-effective integrated solution. System Benefits include:

* Integrate radiation monitors from different manufacturers into a single system.

* Integrate existing monitors into scada, regardless of age and serial protocols.

* Future proof modular design (eg, Future Radnet support)

Features include:

* High isolation analog and digital monitoring.

* Optional IEC61131 PLC control.

* Realtime alarm/event management.

* Low cost networking up to 10 km on twisted pairs.

* Inter-networking for wider area solutions.

* Integrated data logging and multiplexing.

The reliance of some of the world's leading nuclear industries, such as BNFL, on Omniflex technologies, bears testimony to the Maxiflex product performance overall.

For more information contact Ian Loudon, Omniflex, 031 207 7466, [email protected], www.omniflex.com

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved