PPC's cement plant at De Hoek in the Western Cape is currently upgrading its legacy Azon scada system to the technologically advanced, 32-bit, open automation Adroit supervisory control and data acquisition (scada) package. PPC is the oldest and largest manufacturer of cement and lime in southern Africa. Its South African factories have recently been restructured in accordance with a world-class blueprint to yield both quality and cost benefits - as part of this; the Adroit system is delivering monitoring and control functionality to increase plant efficiencies and quality control.

The various temperatures, pressures, flows and raw material characteristics define the quality of the final cement product. Danie Sadie, chief electrical engineer for PCC comments, "One of the main attractions of the scada is the way we have applied the data logging function for quality control." The Adroit scada comprises 31 000 scan points and 17 000 agents. Each tag earmarked for logging is equipped with two log sets and as a result, the 'raw-log' file is extremely fast - logging over 5100 agents per second for a seven-day logging period.

The Adroit scada also logs a 5-minute average value of all analog tags for a period of 400 days. "This allows us to look back with greater accuracy at earlier production runs and to analyse any problems with the current process," says Sadie. Process information required for accounting purposes and the maintenance systems, such as totaliser values, run hour and operations counters are logged via Adroit's DBAccess agents to SQL database tables at an hourly rate.

Located nationwide in South Africa, Adroit were able to incorporate suggestions from PPC Cement to enhance the scada's functionality when it developed its latest release - Version 5.0. Adroit also developed the AREC Agent, a bolstered version of the multistate agent used for complex drive state configuration; added the PID Agent that enables consolidation of up to 27 variables into a single agent and acts as a faceplate for external PID controllers and the Perfmon Agent to monitor PC, OS and application performance counters as a result of its close relations with PPC and other customers in the local market.

The PPC De Hoek control system makes extensive use of the AREC agent to present motor, group and route statuses and control interfaces to the operator. The timing feature provided by the AREC agent also makes it a useful tool to provide intelligent alarming. The new Custom Agent in Adroit 5.0 was also initiated at PPC De Hoek where it was applied as a Splitter agent to break integers up into bytes, nibbles and bits.

PPC chose Adroit after a long evaluation process. Full-scale tests were done on three scada systems on live plant data. Adroit came out a clear leader based on its suitability to adapt to the rigid data structures in the PLCs forced by the old system and the capabilities of Adroit Technologies to develop agents such as the AREC and PID to suit the requirements on site. Willie Lambrechts, the system engineer at PPC De Hoek says, "One of the main requirements for the replacement system was to run in parallel with the current Azon scada. This was achieved without having to change one bit in the PLC programming." Using the standard Adroit OPC device driver, the scada connects with the Applicom network cards, which in turn connect to a mixture of 13 Siemens S5 and S7 PLCs.

The production process starts in the quarry where primary and secondary crushers are used to crush the limestone, which form about 90% of the final cement product. The four raw material components, limestone, sand, shale and iron-ore are proportioned in a ratio determined by the quality control system and communicated between the 'LIMS Adroit' and the main plant Adroit. A separate Adroit server is used to run in conjunction with the laboratory information management (LIM) system.

Raw meal is formed by grinding the raw material in the raw mills, after which it is burned in the kilns to form clinker. The clinker is supplemented with gypsum during the final grinding process in the finishing mills. For PPC's Surebuild range, slag from the nearby Saldanha steel plant is also blended into the cement. The final product is sent to the despatch plant for packing in bags or dispatch in bulk.

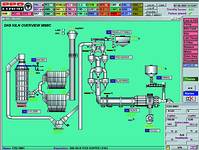

The Adroit scada system is used for the control of the complete plant, from the in pit primary crusher to where the cement is dispatched in bags and in bulk. According to the production manager, Njombo Lekula, the milling and burning phases are the most critical and that is where good mimics, sensible alarming and advanced control features can be very beneficial. "Adroit definitely is a big improvement on the earlier systems in this regard. Its adaptability to meet our requirements and control philosophies is also commendable," says Lekula.

PPC is using BAAN software to service its enterprise resource planning (ERP) requirements. The system, scheduled to go on line in the future will retrieve the relevant process information from the SQL database tables currently populated by Adroit's DBAccess agents.

The architecture is composed of two dual servers in cluster mode. There are six remote workstations in the plant for the control of the primary and secondary crushing stations, the rail tippler, slag blending plant, the packers and the dispatch plant. By far the largest and most complex part of the plant is controlled from the Central Control Room where five workstations are used, two of which are equipped with dual monitors. Two of the monitors are dedicated to trend displays, six trend faceplates on a monitor with three or four trends per window. By doubling up on monitors, PPC is able to save on UI licenses and also on hardware costs.

PPC used standard Adroit graphics to create new wizards depicting cement production related graphics. These graphics are now standard in the Adroit package.

Plant engineers and foremen concerned with critical plant parameters such as bearing temperatures and power usage, have UIs on their desktops via the factory LAN. A stoppage report system application designed with Adroit, logs stop and start times and initiates a stop/start entry for reporting purposes. Operators and management can use this information for cost control vis-à-vis preventative maintenance and resource planning.

The development of the Adroit scada application for De Hoek started in February 2002 and was taken into operation in parallel with the Azon scada in September 2002. The refurbishment of the central control room delayed the final take-over of the plant control by Adroit until June 2003. The development was done mainly with in-house personnel with help from Stuart Atkins, systems engineer at Adroit Technologies to create the standards and to design the various wizards and templates. Mike Lamusse, technical director of Adroit Technologies also played a big part in setting up the system and to develop new agents to meet the exacting standards set by PPC De Hoek.

Adroit Technologies first supplied PPC with its state-of-the-art scada system in 1985 when it installed the product at its Riebeeck cement plant. Since then, the Adroit scada has been installed in the modernised portion of the Port Elizabeth plant and is incorporated as a gateways system to the company's laboratory information system on its plants across South Africa.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved