Wonderware’s new Industrial Application Server, built on architecture by ArchestrA, introduces new opportunities and applications for the FactorySuite A2 Series. Today, manufacturers need to fully integrate their plant systems. They can’t afford to run systems that operate in islands of isolation. The Industrial Application Server (IAS) is here to help bridge those gaps.

Wonderware's new Industrial Application Server is the first product that takes effective advantage of Invensys' new ArchestrA framework. ArchestrA is a comprehensive plant automation and information architecture designed from the outset to extend the life of legacy systems by building upon the latest software technologies, such as Microsoft.NET.

ArchestrA's complete approach to industrial architecture enables products based on ArchestrA to significantly reduce a plant's total cost of ownership through easy installation, operation, modification, maintenance and replication of applications. The Industrial Application Server is also the crown jewel of the evolutionary FactorySuite A2 product line. (The 'A2' indicates the presence of the ArchestrA architecture.)

Wonderware reports that early ArchestrA adopters are making the following comments about the new technologies and opportunities:

* "The modularisation included in ArchestrA is key to the modular automation strategy we are adopting."

* "ArchestrA promises a higher-level functional baseline than many current scada packages, upon which to implement domain-specific applications."

* "Products based on the ArchestrA framework will provide ... a broad foundation to efficiently deploy solutions and automation best practices anywhere in the world."

Thanks to the Industrial Application Server, FactorySuite A2 software now offers tools that enable users to truly address the interconnectivity requirements of today's manufacturing applications. This new era of opportunity empowers FactorySuite users to move outside of the traditional application space and address the ever-demanding need to deliver information to all parts of the business in a timely and reliable fashion. The FactorySuite A2 series will provide the foundation for building a 'manufacturing ecosystem' and will continue to evolve in future releases to meet customers' ever-changing demands.

FactorySuite A2 is not a replacement for existing systems, but rather an extension of them. Whether the existing system is a Wonderware system, a distributed control system (DCS) or a programmable logic controller (PLC) system, the Industrial Application Server, combined with other components, can make it a state-of-the-art automation and information application.

From plants to manufacturing ecosystems

As application engineers focus on seamlessly interconnecting systems, applications, assets and people, they need a solution that traverses information and control systems.

This level of integration requires more than mere inter-communication. It requires common security, history, messaging, alarms and events, user interface, etc. The solution must also enhance the application engineer's ability to add, develop and evolve the complete manufacturing facility so that it maintains a competitive position in the marketplace. FactorySuite A2 provides a significant step for plants to evolve into a manufacturing ecosystem, in which different parts of the plant interact seamlessly, thereby increasing the efficiency of the systems and employees of that plant.

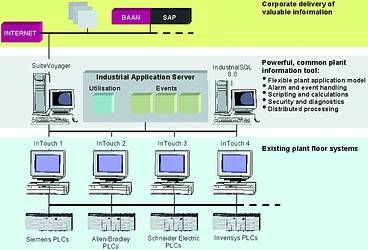

This opportunity is for existing FactorySuite users who want to evolve their applications to the next level, while providing a similar opportunity for those with other systems. For so-called 'green field' sites, the Industrial Application Server combined with the power of the rest of the FactorySuite (InTouch human-machine interface, IndustrialSQL Server historian, SuiteVoyager Web portal and a wide rage of I/O Servers) provides an ideal basis on which to build an automation solution for the 2000s which will be able to cope with change.

Advantages to early adopters

What can FactorySuite A2, and the industrial application server in particular, do for a manufacturer's existing industrial automation application?

Two of the Industrial Application Server's early adopters come from the food and beverage industry, where the modular approach to modelling the batching process is well established with the S88 model. The initial adoption of the S88 approach took place in the 1990s, especially at the control layer, where the unit and equipment control portions were modelled in set structures defined by the S88 standard.

In the 1990s, DCSs allowed for modular programming of control systems and PLC systems offered modular structures, both of which made reuse and diagnostics easier than before. During this period, we also saw S88 Batch structures enter into higher-level batch control. However, manufacturers were still limited because the supervisory tag structure demanded that tags be named into groups.

The Industrial Application Server's early adopters, as well as more than 80 others in the beta program, recognised this shortcoming, which the Industrial Application Server's ArchestrA modular application model solves. The Industrial Application Server is ideally suited to the S88 environment, and immediately overcomes the tag structure limitation.

The following are other examples of how the ArchestrA application model offers flexibility to the food and beverage industry:

* Users can define object structures as templates, using user-defined attributes and extensions, so that the object shape matches the structure defined in the underlying PLC system/ DCS.

* Users can include powerful scripting, alarming, status and security in this template.

* The application model contains objects within objects, allowing for a multilayer approach that matches S88's Process Cell/Unit/Equipment structure.

* Powerful containment provides the ability to assemble process cells, while enabling individually contained objects to maintain their identities and hierarchies and remaining part of the parent application structure. This allows for the highly efficient propagation of changes, when required, during the application's lifetime.

* Users can build a set of standard templates of proven objects for their equipment types, which can become a library of proven functional templates that can be reused from project to project.

The above features immediately stood out for early adopters of the Industrial Application Server. They also recognised the power of the ArchestrA architecture and deployment model, which proved to be significant bonuses during applications development.

Unifying disparate systems

Obviously, early adopters see the benefits associated with the industrial application server, and now others want to see for themselves. Already, a number of customers have approached Invensys/Wonderware about the opportunities to use its Industrial Application Server to realise this unified plant requirement.

Because the Industrial Application Server takes full advantage of the integration capabilities of ArchestrA, it provides an ideal platform for uniting existing 'islands of automation' into one common plant model and information system, without impacting the existing systems. This is crucial because the Industrial Application Server does not force a plant to change its existing systems. On the contrary, it protects prior system investments, and expands the systems' capabilities. Regardless of whether the existing system is a DCS, InTouch system, PLC, Fix 32, Citect, WinCC or some other system, the Industrial Application Server integrates them with FactorySuite, standard OPC or DDE, via one of more than 1000 drivers.

For Wonderware customers currently using InTouch systems, an added interface is supplied with the 'InTouch Proxy', which represents InTouch and allows for namespace browsing as well as other advantages. Those with a Triconex or I/A Series System or a Eurothem Suite can also access standard, powerful interfaces into the Industrial Application Server. Additionally, the new Foxboro A2 Hybrid Automation System will utilise FactorySuite A2 as the supervisory software, thereby offering the full benefits of the Industrial Application Server.

A powerful plant-centric application model

Once interfaced, the user is able to use the industrial application server's powerful plant-centric application model. A user can build templates as standards for their plant equipment types and generate the actual plant model with an instance for each piece of equipment.

Once this unified 'actual' plant model is complete and the interface is made to existing systems at the individual equipment level, the user benefits from:

* One model, across all the existing systems.

* A unified application structure across the systems, in which all data resides in one storage system, making it dramatically simpler to access information and compare data across the plant.

* The ability to easily interact between the different plant systems.

* A structure in which a user can define key performance indicators (thanks to the ArchestrA framework's powerful scripting) in order to fully understand and improve the plant's performance.

* A unified plant model that provides realtime and historical plant data to other systems, such as the Internet, intranets or enterprise resource planning systems (ERP).

Flexible calculation/event engine

From its initial concept stage, the industrial application server has served as a powerful calculation/event engine for Wonderware's IndustrialSQL Server historian, which has been recognised in many early customer reviews. As mentioned above, the Industrial Application Server's ability to unify islands of automation can be extended when the application requires powerful and customisable events, calculations and results storage.

An existing DCS or discrete process in today's economic climate requires optimisation and the Industrial Application Server's powerful scripting and seamless integration with IndustrialSQL Server make the combination a well suited solution. The user can gather all required data from the existing plant system and then build customised calculations and events, which not only get recorded, but can also be monitored as active parameters. The capability for realtime notification across plant systemsor to other applications, such as business or personal systems is also important to achieve successful optimisation.

When the Industrial Application Server and IndustrialSQL Server historian are combined with Wonderware's SuiteVoyager powerful manufacturing portal, users can access historical data in the form of charts and reports (which can be event-driven) as well as realtime data in the form of plant graphics and status screens. This information can empower plant personnel in all roles to do their jobs most effectively and in realtime. (Figure 2 illustrates how the different information layers are related.)

"Essentially, the powerful Industrial Application Server, the significantly enhanced FactorySuite A2 products and ArchestrA software architecture are precisely what manufacturers need to successfully compete in today's competitive business landscape - and they can do so without sacrificing prior investments."

For more information contact Mike le Plastrier, Futuristix Advanced Control Systems, 011 723 9900, [email protected], www.futuristix.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved