Process industries have traditionally maintained three levels of control and instrumentation (C&I) expertise with regards to the installation of new or upgrading and maintenance of existing process instrumentation systems. At one end of the spectrum we have the instrument mechanician whose responsibility is to physically install and maintain the field devices and cabling in the plant. In the middle there is the instrument technician whose main purpose is to terminate and commission the instruments and other field devices to the control room PLC/DCS/scada systems as well as provide some basic PLC programming.

At the other end is the systems integrator who is tasked with the job of designing and implementing the control room environment such as programming PLCs, DCS installation, networking and so on. This model has maintained its general hierarchy for some time but there has emerged a growing need to re-assess the roles and responsibilities of each group, particularly that of the systems integrator.

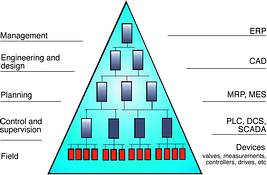

The acceptance of fieldbus technology and the narrowing of the technology divide between analog 4 to 20 mA and digital measuring devices are the driving force behind this need for change. Of all markets that claim to utilise it, including the computer industry, the process industries could be considered to have come closest to the true meaning of the term 'information technology' (IT). The information relevant to the operation of the process is sourced, monitored, manipulated and used to control or change the process. The information highway from the field devices to the ERP (enterprise resource planning) systems has been extended, providing a greater amount of information control over almost every aspect of process plant operation.

In a typical process plant using legacy analog instrumentation, the digital information highway (networks and busses) has been limited to the control room PLCs, DCS and scada, communicating with the upper levels of management and design systems. The instrument technician would be responsible for ensuring a fault-free flow of analog 4 to 20 mA signals from the field instruments to the control room and the systems integrator takes it from the control room to the ERP system in a digital, easy to interpret format. Fieldbus compliant process devices, with their rich digital data and high transmission rates have changed this with the real digital information coming directly from the field. The result is the reduction in the need for control room hardware such as I/O cards in PLCs and the associated programming requirements, a reduction in the amount of cabling, tagging, marshalling racks needed, and the use of configuration software tools for instrument commissioning. The systems integrators, therefore, need to re-focus their position from PLC/DCS programmers to that of contractors or project managers who understand the client's needs from ERP to the actual process. In addition, the systems integrator must be capable of implementing the entire communication system from the field to the control room and from there to the ERP management systems - a total information solution.

A good analogy of this is a company looking to implement an enterprise-wide computer networking solution to run business software and e-mail etc. The IT provider would typically utilise best-of-breed equipment from different manufacturers, while sub-contracting tasks such as desktop PC installation and setup, network cabling, Internet/intranet systems and so on. While the client deals only with the IT provider, the IT provider deals with a number of suppliers. It is this scenario towards which the systems integration profession need to move in the process industry.

Recent events such as the need to reduce costs and to become more globally competitive have seen the downsizing and re-engineering of many large process plants. One of the first departments that get scaled down or closed altogether is the classical instrument department, resulting in the cutting back of skilled personnel. This shortage has forced many companies to expect not only the ability of the systems integrator to design and implement a process communication system but also maintain and modify it on an ongoing basis. The IT industry is a good example of what happens when a company chooses to outsource rather than carry the overhead in-house. A number of highly successful companies provide not only complete IT solutions but also ongoing support, maintenance and upgrading as the client's needs change. There is no reason why this cannot be applied to instrumentation and control in the process industry (Diagram 2).

The three-tier hierarchy to which the process industry has become accustomed is changing. While there will still be the need for the instrument mechanician who can handle the nuts and bolts, the instrument technician's role is under review. Using fieldbus technology, the technician will be forced to upskill to take on the responsibility of the systems integrator and the systems integrator will become true integrators of systems and not just glorified PLC programmers as is generally the case today.

Process instrument vendors such as Endress+Hauser have already made moves to change the way in which they do business. By identifying and working with partners who share this same philosophy, these vendors operate as a combined team co-ordinated by the systems integrator who acts as the prime contractor for the project. Endress+Hauser has formed alliances with companies such as Allen-Bradley, Siemens, Neles Automation, Orsi and their systems integrators and experienced considerable success on a number of local projects as a result.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved