Improving pipe thermal maintenance performance with bolt-on jacketing

July 2001

Pressure Measurement & Control

Maintaining the proper temperature in process lines remains a vital issue in difficult, hot chemical processes. At stake in the solution is product integrity, throughput, freedom from production interruptions, and risks of cross-contamination between the process stream and heating medium. Plant engineers have three principal heating options; tracing, fabricated jacketing, and bolt-on jacketing. Which option provides the best performance and lowest installed cost?

Unless it works right, the price can be several times the cost of the jacketing in a year sometimes with just a single line freeze - in lost production, maintenance, and degraded product. Heating process lines requires careful attention, especially when tight temperature tolerances above 200 F must be held. It is even more important where cross-contamination between process and heat transfer fluids cannot be tolerated. It must be remembered that the principle purpose of jacketing is maintenance of temperature in the line, not heating it up. There is a big difference. That is why the term 'thermal maintenance system' is used. It takes a lot less heat input to maintain constant line temperature than to heat it up in the first place. Too many engineers overlook this fact, and place too much emphasis on recovery rates when evaluating thermal maintenance alternatives. They say the jacketing must get the line back to temperature immediately after a shutdown. While the system must have effective startup/meltout capability, it is a matter of efficiency. Rarely is jacketing (fabricated, bolt-on, or trace) the bottleneck that hinders heat restoration after a shutdown.

Bolt-on jacketing has proven the equal of fabricated jacketing for thermal performance in difficult applications. It also pays dividends with about 25% lower initial cost and lower lifecycle costs for the components it protects. In addition, bolt-on jacketing eliminates the chance of cross-contamination. Inexpensive electric or steam tube tracing is usually adequate for forgiving applications such as freeze protection with broad temperature ranges and moderate service temperatures.

At higher temperatures, differential expansion can cause tracing lines to warp and pull away from the pipe, causing cold spots. Sensitive processes require the incrementally greater thermal performance of high-integrity fabricated or bolt-on jackets, or a combination of both. But, for the majority of difficult cases, the bolt-on option is equal to the task. The choice between a fabricated or bolt-on system should be based on comparative cost and risk of cross-contamination.

Figure 1. Typical bolt-on fabricated jackets protect valves, pumps and meters

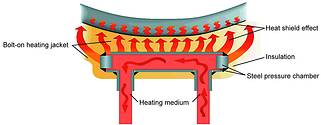

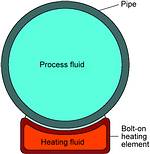

Typical bolt-on heating systems consist of jackets for components such as valves, pumps, and meters (Figure 1) and heating elements for piping and vessels. The component heater is made of an aluminium casting with a steel pressure chamber embedded inside the aluminium (Figure 2).

Figure 2. Bolt-on jacketing for valves, pumps, and meters fits snugly for heat transfer and is easily removed for valve repair or exchange

Heat is transferred from the heating fluid contained in the pressure chamber through the casting, which fits the component like a second skin. The pipeline-heating element is a basically rectangular tube with one surface contoured to closely fit the outside of the pipe or vessel (Figure 3).

Figure 3. Bolt-on heating elements detach from piping for maintenance and repair and cost less than custom fabricated jacketing

In difficult and hot processes, the use of bolt-on thermal maintenance systems has doubled over the past decade, replacing custom-fabricated jacketing. Less costly than fabricated jackets, bolt-on component jackets are easy to install and remove for maintenance or component exchanging. In addition, with an independent barrier between heat transfer and process fluids, bolt-on elements provide security against cross-contamination. Industry standard bolt-on component jackets are available to fit more than 4000 models of valves, pumps, and meters.

Instead of stocking expensive, permanently jacketed valves and pumps, users of bolt-on elements can stock standard components at a fraction of the cost and simply switch the jacketing when necessary. In very hot processes requiring frequent replacement of valves, pumps, and meters, bolt-on solutions can cut spares costs by up to 50%.

Valve & Automation

(031) 579 2593

(011) 397 2833

[email protected]

www.csiheat.com

Further reading:

Water under pressure

VEGA Controls SA

Pressure Measurement & Control

The need for real-time monitoring and precise control over water distribution has never been more critical. VEGA’s range of pressure sensors and level instruments plays an important role in ensuring that water systems operate efficiently.

Read more...

Paper might carry the message, but pressure carries the process

VEGA Controls SA

Pressure Measurement & Control

VEGABAR pressure transmitters are designed to address the unique challenges faced by the pulp and paper industry. Built for durability and precision, they ensure reliable pressure monitoring in aggressive environments.

Read more...

Capsules, steam and cream

VEGA Controls SA

Pressure Measurement & Control

African cosmetic brands are increasingly outsourcing production to specialised contract manufacturers who use automation and high-precision tools to ensure quality and adapt quickly to regulatory changes. VEGA’s suite of level and pressure measurement solutions offers a robust foundation for profitability and quality assurance.

Read more...

Differential pressure measurement made simple

VEGA Controls SA

Pressure Measurement & Control

The VEGADIF 85 serves as an exemplary model of a differential pressure sensor. It combines universal applicability with high operational dependability and integrated overload protection, ensuring consistent performance even in the harshest conditions.

Read more...

Smart pressure monitoring drives energy efficiency

ifm - South Africa

Pressure Measurement & Control

The ifm PG17 electronic pressure gauge is part of the company’s next-generation PG series. It integrates IO-Link technology, enabling seamless, loss-free data transmission via a 24 V signal.

Read more...

Electronic manometer with LED display

ifm - South Africa

Pressure Measurement & Control

The new generation of PG type manometers are equipped with IO-Link and modern display units. Illuminated LED markings provide a quick overview of the current measured value. In addition to the various setting options for the display unit, IO-Link offers other advantages such as easy commissioning, quick sensor replacement and remote access options.

Read more...

Rapid, precise pressure control for industrial applications

WIKA Instruments

Pressure Measurement & Control

The CPC3050 high-speed pressure controller delivers rapid, precise pressure control for industrial applications, achieving three-point verification in ten seconds.

Read more...

Differential pressure measurement in gas extraction and power generation project

VEGA Controls SA

Pressure Measurement & Control

Methane exploration and extraction in Lake Kivu in the East African Rift Valley has primarily focused on gas composition analysis. The VEGABAR 82 pressure transmitter was used for differential pressure measurement, the key to monitoring gas levels within the lake.

Read more...

Don’t buckle under pressure

VEGA Controls SA

Pressure Measurement & Control

In Africa, urban populations are increasing and infrastructure is expanding at an unprecedented pace. This makes sustainable water management and treatment more crucial than ever. By investing in VEGA pressure instrumentation, water utilities and municipalities are equipping themselves with pressure sensors that facilitate sustainable water management focused on efficiency, reliability and resilience.

Read more...

VEGA handles the pressures of water treatment systems

VEGA Controls SA

Pressure Measurement & Control

A water treatment system for a major metropolitan area in the Midwestern United States demands careful monitoring and management of processes across its sprawling network. Choosing VEGA for its process automation needs meant more than just obtaining precise and reliable pressure sensors.

Read more...