Electromechanical relays (EMRs) or solid-state relays (SSRs) are used for switching various loads in numerous industrial fields. These switching devices generally operate reliably in the control cabinet at the most commonly used voltage levels 24 VDC and 230 VAC. If, however, DC loads have to be switched at higher voltages, often with higher powers at the same time, the common standard versions of the EMRs and SSRs prove to be unsuitable, and often fail quickly.

Applications for the switching of higher DC loads can be found in numerous industrial sectors. Examples include electric motor vehicles with up to 800 VDC, battery voltages on trains, and photovoltaic systems with up to 1000 VDC. Due to the application-specific switching requirements and the simultaneously occurring high currents, the relay manufacturers have developed special devices for those applications. However, these devices are often unsuitable for the control cabinet applications implemented in automation solutions.

Use of DC voltage from battery systems

For the most part, the control cabinets in industrial automation solutions use the common voltages of 24 VDC and 230 VAC, as well as three-phase systems for mainly motor-driven applications, operating at higher voltages. At a closer look, however, DC voltage systems operating at more than 100 VDC can also be found, normally used as battery-based emergency power supplies in case the mains voltage fails. Such solutions are used in computer centres, airports, in the chemical industry, in process engineering, in power plants for electricity generation, etc.

To maintain uninterrupted operation, even when a malfunction occurs, power plants have emergency power generators. When these also fail, large battery systems need to ensure that the important parts of the power plant can operate in emergency mode for a certain period of time. In Europe, such applications preferably use 220 VDC battery systems, whereas also 110 and 125 VDC solutions can be found in other parts of the world. In order to supply the very high power required, a significant number of individual cells are connected in a large battery system. Numerous loads from the control system, including many switching devices such as contactors and coupling relays, which are conveniently snapped onto standardised DIN rails in the control cabinet, are directly supplied by the DC voltage from these batteries. In contrast, three-phase loads – such as pumps – are supplied indirectly by the batteries via rotating transformers or converters.

No voltage commutation with DC voltages

What are the reasons that cause standard coupling relays in such applications, often installed due to a lack of insight, to fail so quickly? The answer can be found considering the completely different behaviour of coupling relays when switching AC or DC voltage. On that point, a brief digression into the physical basics: almost all of the standard coupling relays available today have contact clearances in the range of 0,3 to 0,4 millimetres. These clearances are perfectly sufficient to switch off loads up to 230 VAC, even at higher currents. Not later than after one half-wave of the sinusoidal mains voltage, the voltage commutates and thus ensures that any electric arc possibly igniting at shutoff is extinguished automatically. Naturally, with DC voltages, there is no voltage commutation, which is why the maximum permissible switching current decreases drastically, especially with higher switching voltages.

Generally, users don’t know about the differences in relay behaviour because the interruptible current turns out to be absolutely identical (10 A for a suitably rated coupling relay) at the voltages of 24 VDC and 230 VAC commonly used in automation solutions. However, in applications where the DC voltage to be switched is significantly higher – 220 VDC, for example, the 10 A coupling relay can only switch off 0,3 A. This is why, unfortunately, misuse occurs frequently, leading to a total failure of the standard coupling relays, sometimes even during the first switching cycle.

Integration of an additional magnetic arc blowout solution

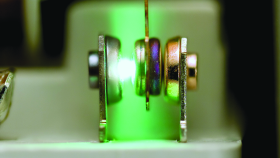

The explanations above emphasise that common coupling relays are not suitable for switching off higher DC loads. Consequently, automation applications also require special solutions. The integration of an additional magnetic arc blowout solution has proven helpful here. The functional principle is simple: a permanent magnet is integrated into the contact gap of such a special relay.

Any electric arc igniting at shutoff will now be deflected in the magnetic field in accordance with physical laws. Instead of, as before, striking directly at the point where the distance between the opened relay contacts is shortest, the electric arc deviates laterally between the contacts. Because this looks like the electric arc is blown out of the gap, the relays are called magnetic arc blowout relays. The electric arc becomes significantly longer, and even the higher DC switching voltage is not sufficient anymore to help maintaining it. Thus, the electric arc extinguishes within a few milliseconds. Usual coupling relays of such type safely switch off loads up to 220 VDC and 10 A – 30 times higher than relays of the same design without blowout magnet.

Purely electronic switching by high-voltage MOSFETs

Another interesting alternative for switching loads at higher DC voltages is the use of modern solid-state relays (SSRs). The key here is the use of high-voltage MOSFETs. So, up to voltages of 300 VDC, switching is done electronically, with no electric arcs ever occurring. Consequently, there is no wear either. Such devices outperform electromechanical relays not only with regard to their service life: they do not bounce, and moreover, switching is fast and completely silent. Even if the solid-state relay can ‘only’ switch loads of up to 300 VDC/1 A, it tops conventional standard relays by a factor of 3 to 5 while offering the above-mentioned advantages. Moreover, the SSR has proven to be space-saving with its overall width of only 6,2 mm.

A third approach to the switching of higher DC loads is the contact series connection of several N/O contacts or N/C contacts of a conventional multi-position coupling relay. Depending on the number of contacts connected in series accordingly, DC switching currents in the low one-digit ampere range can be reached at a switching voltage of 220 VDC. Information on the interruptible current is provided in the relay manufacturer’s load limit curve, if determined for this special type of connection.

Summary

Trouble-free switching even of higher DC loads up to 250 VDC and 10 A can be realised by means of selecting a special coupling relay, preferably with blowout magnet. The use of these powerful devices eliminates the need to expect troubling failures such as those occurring in similar applications with conventional standard relays, where continuous electric arcs occur. In applications with switching voltages of up to 300 VDC as well as maximum currents of 1 A, the high-voltage SSR presented can be an interesting alternative to its electromechanical equivalent. This is because it is only as wide as a terminal block (6,2 mm) and it switches completely wear-free.

For more information contact Sheree Britz, Phoenix Contact, +27 11 801 8200, [email protected], www.phoenixcontact.co.za

| Tel: | +27 11 801 8200 |

| Email: | [email protected] |

| www: | www.phoenixcontact.co.za |

| Articles: | More information and articles about Phoenix Contact |

© Technews Publishing (Pty) Ltd | All Rights Reserved