Schneider Electric is dedicated to the deployment of digital technologies in mining to address the rising pressures on business sustainability and reduced energy consumption.

“The organisation has invested significantly to develop a specialised competence in mining applications,” explains Marc Ramsay, vice president industry business unit at Schneider Electric South Africa. “We believe that technology integration combining energy management, process automation and software through our IoT enabled platform, EcoStruxure, leverages an enabled, open and interoperable architecture to deliver true digital transformation. EcoStruxure enables customers to maximise the value of data and edge control, which translates into actionable intelligence for better business decisions.

“One of the challenges has always been to make real-time decisions based on information that is spread across disparate databases locked within mining hierarchical disciplines. With that in mind, we believe that our technology provides a high level of value through breaking down operating silos both vertically and horizontally across the mining value chain. Connected devices can now be safely and reliably accessed from the cloud and product deliveries can be traced in real-time.”

A truly unique time in mining

“Operational efficiency is still below global benchmarks and plagues our mining industry,” outlines Ramsay. “The management of asset utilisation is a core focus for Schneider Electric’s mining team. Whether we are reducing the mean time to repair of our medium voltage switchgear, or using augmented reality for embedded equipment fault diagnosis, we are dedicated to reducing operating costs and improving the efficiency of equipment and workforces.

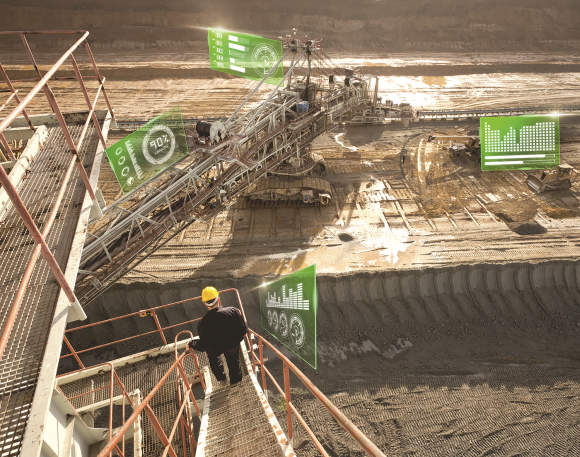

“We believe that an important aspect of digital transformation is the human aspect, and while autonomous operation continues to be a compelling and necessary aspect of mining operations, future workforce integration should not be neglected. Already our customers are benefiting from the adoption of EcoStruxure Augmented Operator Advisor, which combines contextual and dynamic information for mobile users. The technology enables them to experience a fusion of the physical environment with an added layer of virtual objects and critical information.

“The mining industry is also a large consumer of electrical energy. Our mining teams work with customers to manage their energy footprint and consider all aspects of the efficiency of the mining process to serve this requirement. Schneider Electric has been delivering complete solutions for the mining industry from low and medium voltage equipment, to transformers and grid automation, for over 150 years. The latest integrated IoT-enabled power management architectures enhance connectivity, network security, real-time operational reliability, and smart analytics for peace of mind and significant financial benefits.”

According to recent studies conducted by independent research companies, autonomous and mechanised mining can have a significant impact on extending the economic life of existing operations, as well as the profitability. But one needs to be cognisant of the impact on jobs, despite the improved safety related aspects of autonomous operations. Schneider Electric has already experienced digital transformation in its own teams and the impact that a digital frontier requires on different working methods. Therefore, the technologies it develops are always with the digital worker in mind, along with the built-in capability to integrate a mobile or transient workforce. Studies have documented that the workforce of the future will on average not stay in their jobs for more than 36 months, and this transition will be amplified in the mining environment, which requires a new level of induction and orientation, along with the workforce having on-hand access to latent or ‘hidden’ operational knowledge. The good news is that digitisation is not only driving operations, but also enabling internal research and development teams to incorporate previously inaccessible technologies in a plug-and-play fashion. Open standards and the adoption of industry protocols has always been the company mantra.

“Of all the trends impacting the mining industry, few will be as critical as effective digitalisation,” concludes Ramsay. “It will affect every aspect of industrial operations and provide the greatest potential for improving business and operational efficiency. The rewards are significant for those willing to explore the potential. It has been estimated that in the next five years, mining industry leaders will achieve their most significant improvements by embracing digital technologies such as the IIoT, advanced analytics and augmented reality that harness the power of big data in a secure way.”

| Tel: | +27 11 254 6400 |

| Email: | [email protected] |

| www: | www.se.com/za/en/ |

| Articles: | More information and articles about Schneider Electric South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved