Measurement specialist Keller offers probes to monitor groundwater and filling levels in tanks under a wide range of conditions. Depending on requirements, these devices provide fully autonomous operation, or they can be used with an integrated data logger, wireless transmission (GSM), an ambient pressure-compensating capillary, or a separate absolute pressure sensor. Depending on the sounding tube, probe diameters of 16, 18 and 22 mm are available.

Thanks to its diameter of only 16 mm, the DCX-16 can be used in locations where every millimetre counts e.g. for sounding tubes with small diameters. The pressure sensor is welded into the logger housing and the unit, which is fully watertight once screwed into position, operates as an autonomous battery-powered data collector with an absolute pressure sensor. In shallow water, a second logger (barometer) can be used for separate recording of the barometric pressure on the surface. The differential pressure and/or the filling level are then calculated in the PC by processing the time-stamped measurement data from the individual loggers. Version DCX-16 SG/VG provides a cable connection, wherein barometric pressure is fed to the sensor as a reference, via a compensating capillary in the connecting cable. There is no need to remove these loggers from the sounding tube in order to read the data as the interface plug is secured on the sounding tube by a fixing device.

The fully-welded DCX-18 (18 mm) is designed as an autonomous level logger for low-cost measurements of level and temperature. The microprocessor electronics compensate for linearity and temperature deviations by the pressure sensor, achieving a further increase in the accuracy of the pressure and temperature signals. Different operating modes, with an absolute pressure sensor or an overpressure sensor with a pressure-compensating capillary, can also be supplied for the DCX-18. The measurement data is stored in a non-volatile memory and the batteries are fast-charged every time data is extracted via the read-out plug.

Type DCX-22 level loggers (22 mm) register and compensate for fluctuations in the local barometric pressure via a watertight air pressure sensor that is fitted on the top end of the sounding tube. These devices are resistant to damp environments, and will not even be damaged by brief flooding. The efficient electronic equipment registers the signals from the high-precision pressure and temperature sensors, corrects linearity or temperature deviations according to a mathematical model, and then records the values to the internal memory. For standard operation, the built-in battery has a lifetime of 10 years.

For larger sounding tube diameters, the data loggers can operate in conjunction with a screw-on wireless data transmission unit (GSM). It is then easy to send the measured values to a central unit where user-friendly software the GSM-2 DataManager then performs the key functions of a monitoring, collecting, controlling and organising unit in the central PC. The DataManager collects the measurement data, assigns it, visualises it in graphic form, signals threshold value violations as appropriate, and finally stores the data in a mySQL database. Various export and Internet functions enable third parties to access the measurement data for integration into a data recording system.

Static groundwater measurement

Traditionally, a conductivity switch that emitted an acoustic signal when it hit the water was used to measure groundwater levels. Nowadays these measurements can be made automatically using Keller’s DCX22 and DCX 22AA level probes, which are both autonomous level dataloggers made up of a level sensor, a microprocessor with memory and a battery. They are programmed in advance to perform a measurement (for example every six hours), store this in memory and then go back into sleep mode. Programming and readout of the data is done via a K114A USB cable and Keller’s logger 5.2 Windows-based software, running on a laptop or PC.

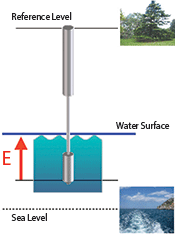

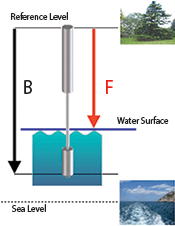

DCX22(AA) dataloggers can only measure the water column above the diaphragm of the sensor (labelled E in Figure 1). However, most geohydrologists are interested in the distance from the top of the borehole to the actual level in the borehole. Figure 2 shows how converting the water column to the ‘depth to water’ can be achieved quite easily. In the datalogger the total installation depth (B) is programmed as a passive parameter: when the measured water column is deducted from the installation depth, the depth to water value (F) remains. The calculation is therefore B-E = F.

An important thing to remember is barometric compensation. When a level sensor is placed in a fluid, it measures the fluid column + the air column that rests on the water. If no correction is made, the measured value would not be correct as 1mbar equals 1 cm of water. Thus the barometric pressure must be deducted from the hydrostatic pressure.

There are several ways to do this. The most applied method with conventional level sensors is the use of a capillary, which is a tube in the level sensor’s cable so the air pressure can ‘push back’ on the reverse side of the diaphragm. This mechanical air pressure compensation has one associated risk, that of condensation in the tube, causing damage to the sensor.

Another way is the use of a second pressure sensor to measure only the air pressure: when the signals are subtracted from each other, only the pure water column remains.

The difference between the DCX22 and the DCX22AA is the integrated barometric compensation in AA, which has a second (barometric) pressure sensor in the battery pot at the head of the borehole. The unit can store hydrostatic, barometric and the barometric compensated water levels.

Case study: wireless groundwater monitoring system

Since 2007 the Polish Geological Institute has been using some 200 Keller DCX-22 data collectors. As in this application the monitoring process needed to be automated, the remote data transmission unit and data logger GSM-2 seemed to be the perfect solution. The data collectors are mostly placed in custom-built wells called piezometers. Thanks to the highly robust mechanical construction (waterproof stainless steel housing) and low power demands, the DCX-22 was an ideal solution for the customer’s needs.

The GSM-2 module allows the data transfer using SMS, FTP or email. Furthermore, the collected data is saved in a buffer with a capacity of 57 000 samples, which additionally increases the security of the collected data.

The barometer installed inside allows using a capillary free, extremely stable absolute pressure sensor for water level measurement.

The level probe used in this application is a PAA-36 X W with a total error band of 0,05% (0-40°C) and water temperature measurement is carried out by an optional Pt1000 sensor reaching 0,1°C accuracy. The low voltage electronics requires a supply of only 3,2 V, and guarantees a battery life of several years. The lack of a capillary greatly increases the reliability of the system by eliminating any humidity problems.

The system was recently expanded to include 350 groundwater monitoring stations based on GSM-2 modules installed around the country, all sending the information on water level and temperatures directly to the main control station in Warsaw.

For more information contact Instrotech, +27 (0)10 595 1831, [email protected], www.instrotech.co.za

| Tel: | +27 10 595 1831 |

| Email: | [email protected] |

| www: | www.instrotech.co.za |

| Articles: | More information and articles about Instrotech |

© Technews Publishing (Pty) Ltd | All Rights Reserved