Mitsubishi Electric has introduced a solution that promotes further energy efficiency in factories.

To create this energy-saving factory automation solution, the e-F@ctory concept for optimising factories through visualisation and eco-Factory technologies that contribute to energy conservation through visible management of specific energy consumption, were merged.

The merging of e-F@ctory and eco-Factory is essentially the merging of productivity improvement through visualisation of the manufacturing floor and energy conservation through visible management of energy.

e-F@ctory = solution for advanced factories of the future – control and network technologies

e-F@ctory promises enhanced productivity. It makes full use of leading-edge control technologies and network technologies to ‘visualise’ production information, including quantitative and qualitative production data and equipment information, and links production equipment to higher manufacturing execution systems to allow production information to be incorporated into production plans and be utilised to ensure quality traceability.

eco-Factory = proposal for aggressive energy conservation – power receiving and distribution and measuring technologies

eco-Factory allows ‘visible management’ of power usage through the introduction of measuring equipment and technologies that support energy conservation efforts by meticulously measuring power usage. It also promotes the effective installation of inverters and other energy-saving devices to not only eliminate wastefulness and surges in energy consumption but to reduce overall power usage.

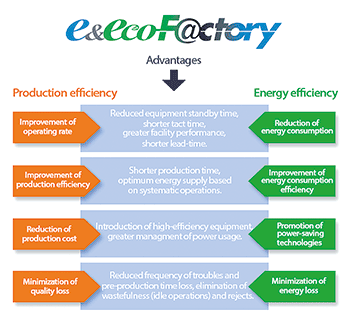

Production efficiency and energy efficiency in factories essentially both aim at achieving the same goal of total cost reduction. In no way do they conflict with each other. Mitsubishi Electric’s e&eco-F@ctory is a factory automation energy solution based on a new concept of realising both production efficiency and energy efficiency. It brings large advantages to factories from two perspectives.

The e&eco-F@ctory concept is made possible by Mitsubishi Electric’s strong expertise in factory automation and power distribution/control technologies.

Measure, visualise, reduce and manage are the steps to energy efficiency. By linking production equipment measures to energy efficiency, we can identify areas for improvement and explore how improvements can be made. Based on this we can confirm the manufacturing efficiency (specific energy consumption), of each product and facility resulting in improved energy efficiency in each plant.

e&eco-F@ctory realises factory-wide optimisation through effective utilisation of energy information. Transforming a factory into an e&eco-F@ctory means optimising it from an energy perspective. In an e&eco-F@ctory, production and energy information is visualised and linked together for thorough energy management. Furthermore, the different situations of energy use by different production lines are accurately assessed and their energy use is analysed to ensure factory-wide energy optimisation.

Measure energy usage

Once you have detailed measurements for each device and piece of equipment, the way to increased productivity is clear. The important thing to comprehensively visualise energy is to measure the amounts of energy being used in the shop floor in real-time and collate the data, but also to keep an accurate grasp of specific energy consumption, with linkage to production volumes and other manufacturing information. e&eco-F@ctory aims to improve equipment working efficiently through detailed work analysis. It measures the specific energy consumption by production equipment and devices for every task time, every product type, and every process. It links to work monitoring of production lines, preventive maintenance of equipment and improved productivity.

Visualise energy usage

The visualisation of energy and productivity information serves as an indicator of improvement. Improving productivity efficiency by managing specific energy consumption is a priority issue on the shop floor. The key to achieving this lies in linking energy information obtained from each production equipment and device with production information from the shop floor, and assessing production efficiency and manufacturing cost of each part, product, equipment and work process from an energy perspective, by utilising production energy efficiency as an indicator of improvement. e&eco-F@ctory utilises FA-IT information communication products and HMIs to communicate production equipment information, so that wasteful and inconsistent work processes can be discovered from an energy perspective and effectively improved.

Reduce energy usage

Overall energy efficiency starts with energy-efficient equipment. Even using the latest visible technology and taking meticulous measurements of your shopfloor’s energy information will not boost your energy efficiency if your production equipment itself is inefficient. Start by implementing equipment built for efficiency and energy conservation, and you will raise your production efficiency while lowering energy consumption. Then give your equipment higher performance and you can optimise your plant in total.

Manage energy usage

Solutions that make energy use visible are powerful tools for your energy management programme. Real-time monitoring of your equipment’s total and specific energy consumption is critical to linking production information and energy information and making improvements. This lets you discover problems, find where to make improvements, focus on reducing consumption and decide what improvements to make. The e&eco-F@ctory system uses dependable solutions from our partners to smooth out and continuously improve the POCA cycle of energy efficiency.

Achieve productivity enhancement and total cost reduction through effective utilisation of energy information with the e&eco-F@ctory solution.

For more information contact Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved