About OPC

Kepware Technologies develops a wide range of communication and interoperability software packages for the automation industry. The scalable solutions are designed for connecting, managing, monitoring and controlling diverse automation devices and software applications. Communications are managed through a robust software platform that supports an array of open standards, propriety communication protocols, APIs, and automation systems’ interfaces.

The OPC UA (Unified Architecture/Tunnelling) standard facilitates efficient and effective OPC connectivity over wireless and Web communication mediums. Kepware’s OPC Server, KEPServerEX, provides a centralisation point for data from numerous different data sources e.g. PLCs, databases and other devices. This centralised data, in an open OPC server format, provides most industrial and commercial software applications with access to it. There are numerous automation and industrial IT applications available on the market today and most will have an OPC client interface capable of interfacing with OPC servers.

Energy analysis monitoring system foils excessive energy consumption

Over the last few years, energy consumption and costs have risen to the extent that they are now squarely in the spotlight. Industrial consumers have been forced to become ‘wise’ consumers of resources such as gas and electricity so as to remain competitive.

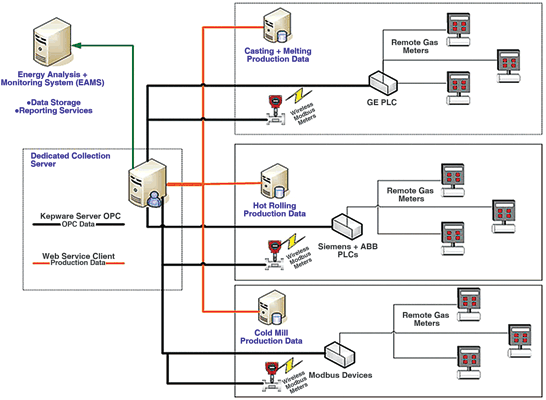

In order to ensure natural gas usage remains constant in relation to manufactured tonnage, solution provider, Deadline Solutions, came up with a system to provide reporting and trending of natural gas usage within the aluminium industry. In order to accomplish this, two key variables need to be harvested: gas usage in and tonnage produced over time. The consumption and processing of these variables becomes the Energy Analysis + Monitoring System (EAMS).

Where is the gas being consumed?

Within most aluminium facilities, there are a number of existing natural gas meters in place to help trend the gas usage. But, one of the first obstacles to be overcome is the disparity of control systems that contain the flow data within the factory. Some facilities will have a casting group and hot and cold rolling lines that may contain a variety of control equipment from different manufacturers.

To solve this problem, Deadline Solutions selected Kepware Technologies to provide a ‘landing zone’ for all natural gas readings, combining them into one process flow. Kepware OPC (open connectivity) software can communicate with all the various PLCs within a site. In particular, the requirement was to solve this problem by connecting to Allen-Bradley, Yokogawa and GE 9070 PLCs, as well as various Modbus devices. Out of the box, Kepware has a solution for each of these to provide a single source concentrator of OPC data. With all of the OPC data contained in one location, trending and management of these variant natural gas flowmeters becomes routine.

In order to obtain a high degree of accuracy, secondary gas flowmeters need to be installed to fill any gaps in the existing infrastructure. Here, the use of wireless technologies is employed to save on material and labour costs. The secondary network therefore consists of wireless RF modems providing coverage over the entire site. Essentially, wireless flowmeters’ configuration can now be placed anywhere within the facility without concern for location dependant resources such as wired LAN connectivity. Base stations are placed at key locations to accept the wireless data and ground it to the automation LAN. Once the data is available on the LAN, the Kepware Modbus driver collects and stores the flow data for EAMS.

What was done with the data?

As with the flowmeters, production data presents a similar challenge with different MES/Level 3 systems used within the facility. The production data was harmonised into a common format so it could be understood by computation logic within each plant area. Putting software engineering best practices to use, Deadline Solutions built a Web Services layer in front of each of the manufacturing units to provide endpoints that can transgress routed and firewalled environments. Each area contains a Web server that publishes the tonnage data as secure standardised the information in a central store. The production data is now stored in a consistent uniform manner across all the disparate systems.

What is the outcome?

By marrying three technologies: wireless process measurement technology, Web Services and Kepware OPC data, the EAMS system now has the required data inputs to make reporting and reviewing of natural gas consumption an easy task. This enables answers to questions such as: How much gas was used? How many BTUs per ton where used? Is the furnace or process more efficient this week from last week?

Being able to answer these questions provides the feedback to maintenance and process personnel necessary to optimise the devices and processes. This enables manufacturers to be conservationists of energy rather than simply users. The benefit is an increase on the bottom line.

For more information contact Neil Upfold, eTX Data Services, +27 (0)83 325 4139, [email protected], www.kepware.com

© Technews Publishing (Pty) Ltd | All Rights Reserved