Problems on a flow control loop

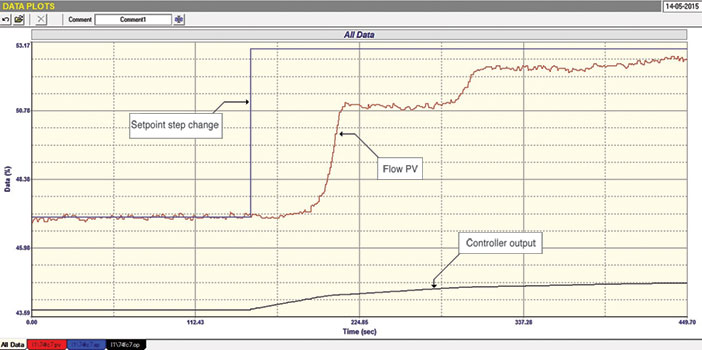

The first example is that of a flow control loop on a liquid flow. Figure 1 shows a closed loop test with a step change of setpoint.

Three problems immediately stand out:

1. The tuning is terribly slow.

2. The valve is sticking badly. It takes a long time to move then sticks several more times as it opens.

3. The valve is probably extremely oversized which can be seen by the huge step in PV as compared with small step in the controller output.

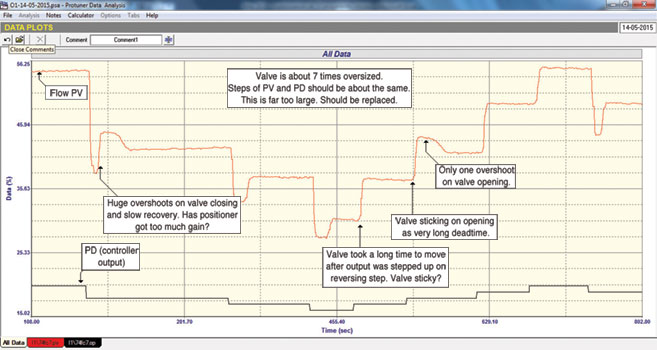

Figure 2 shows the open loop stepping test. This confirms deductions 2 and 3 made from the closed loop test. In particular it shows that the valve is at least 7 times oversized. In addition another extremely serious problem has been uncovered, namely that the valve overshoots really badly, particularly in the closing direction, and the positioner takes an extremely long period to correct the overshoot. These factors make good control almost impossible.

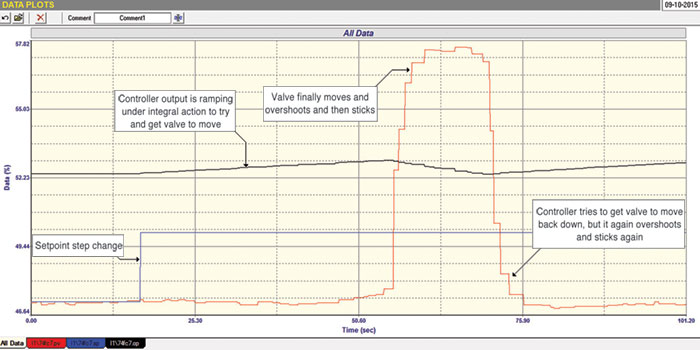

This is confirmed in Figure 3 which is closed loop and shows a setpoint step change made with much better tuning, which was kept as slow as possible to try and overcome the problems of sticking and overshoot. However, it did not help as the valve stuck and then hugely overshot. The controller tried to bring it back, but the same thing happened in reverse and the valve is now in what could be described as a terribly slow stick-slip cycle.

Problems on a pressure control loop

The second example is an interesting pressure control loop. The operators were always complaining about this loop, which they had to try and control in manual as it did not control in automatic.

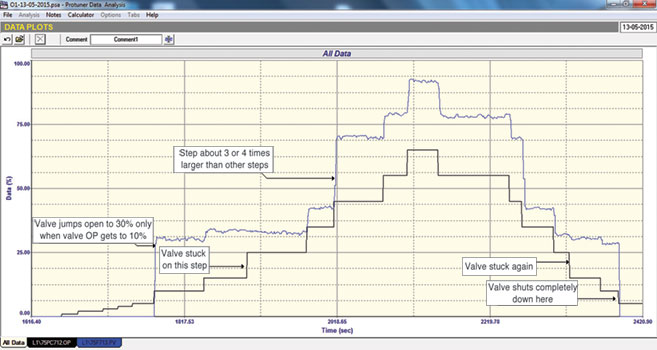

A closed loop test with the existing tuning parameters was tried, but nothing seemed to happen when a setpoint step change was made. Very fortunately there was a flowmeter in series with the valve, which allowed us to examine the valve performance. The open loop stepping test showing the flow versus the controller output is shown in Figure 4.

The following extremely serious valve problems were revealed:

1. There is no valve movement until the controller output gets above 30%.

2. The valve is very sticky.

3. When making the same size steps on the controller output the valve response is very erratic and non-repeatable with big movements in some places, and small in others. At times it didn’t move at all. This makes any reasonable control impossible.

However, further testing of the actual pressure loop showed it to have extremely slow dynamics, and in fact crude but reasonable pressure control was obtained, by running the loop with “ON/OFF” control, that is with the valve either fully open or closed. This is equivalent to controlling the temperature in a bath, as opposed to “throttling” control when controlling the temperature of a shower.

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering cc, +27 (0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved