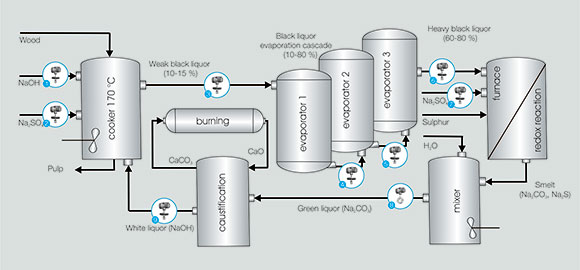

One of the most important processes in the pulp and paper industry is the alkaline sulphate process, where lignin is separated from the fibrous material. Recycling of the chemicals used is vital for environmental and economic reasons. During the recycling process, black liquor will be concentrated and burnt to remove organic materials like lignin. This recovery process generates – in addition to energy – a smelt with high salt content, the base material for green liquor. Through causticising with lime, the sodium carbonate in green liquor is converted to sodium hydroxide and reused in white liquor for the next pulping process. LiquiSonic analysers ensure each process step is inline monitored and set in an optimal way. The analyser system provides optimised quality control and productivity, especially through fast process monitoring during liquor recycling.

LiquiSonic measuring technology in the sulphate process

Black liquor

The base materials in the kraft or sulphate process are wood chips and alkaline cooking liquor, which mainly consists of recycled white liquor, hot caustic soda (NaOH) and Na2SO4. The cooking at typically 170°C is also known as the delignification process, where lignin is separated from the fibrous material and pulp. The resulting black liquor contains NaOH, Na2SO4, lignin, carbohydrates and hemicellulose. In multiple black liquor recovery evaporators, the dry matter is increased from 10-15% up to 70%. LiquiSonic provides robust and accurate concentration monitoring and enhances operational safety due to high-water content that interrupts the burning process. PFA coated flange sensors work maintenance and drift free with no cleaning adaptor needed, even for alkaline hot liquids with high coating tendencies.

Green and white liquor

In the black liquor furnace process an inorganic salt-rich smelt is formed. The molten salts sediment on the ground of the recovery boiler and must be diluted by water or weak white liquor, resulting in green liquor, rich in Na2S and Na2CO3. Green liquor is often collected in a separate stabilising tank before it is clarified. During clarification of green liquor, dregs must be removed. Clarified green liquor is used for causticising, a recycling step, where CaO lime is used to regenerate NaOH for white liquor. LiquiSonic provides quality improvement, like real-time green liquor concentration monitoring for optimally regulated lime dosage in causticizing. This increases the recovery process efficiency, lime burning recycle numbers and white liquor quality.

Advantages of LiquiSonic technology

• Robust and maintenance-free even for hot (up to 200°C) and high coating liquors.

• Layer-free, no steam wash system necessary.

• No frequent mounting and dismounting for maintenance and cleaning.

• Reduced laboratory costs.

• Highly accurate inline concentration measurement of green, black and white liquor (up to 0,1 wt%).

• Ideal lime dosage in causticising.

• Enhancement of operational safety.

For the high demands that are placed on sensor technology in the pulp and paper industry, LiquiSonic analysers have been built to withstand the harsh working environment and can be adapted to existing process conditions.

For more information contact Morton Controls, 086 100 0393, [email protected], www.mortoncontrols.co.za

| Tel: | +27 21 557 9011 |

| Email: | [email protected] |

| www: | www.mortoncontrols.co.za |

| Articles: | More information and articles about Morton Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved