SKF SimPro Quick is a single-shaft bearing simulation tool that has been developed to evaluate the design of bearing arrangements and their field performance based on relevant application requirements and conditions.

Industrial manufacturers face new challenges every day when it comes to rapid design of more robust and more cost efficient machines. To maintain a competitive edge in product performance through innovation, design engineers are increasing the use of computer software all the way through their design cycle; exploring new design alternatives, including more parameters, and reducing time to market.

Design engineers recognise that critical bearing arrangements are fundamental for machine performance, especially with the increasing variety of application conditions. An effective evaluation of bearing performance without compromising on time and flexibility is crucial in order to choose the best possible arrangements for machine design.

SKF has core expertise in bearings, seals and lubrication, and more than a century of experience with applying bearings in rotating machinery in a wide variety of industries. SKF SimPro Quick is aimed to provide customers with more engineering knowledge and autonomy in order to accelerate the design process and optimise bearing choice.

Intuitive interface

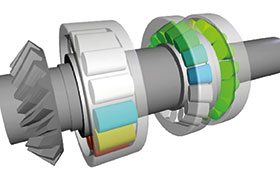

The software tool has an intuitive interface to model the customer’s application, with relevant components such as shafts, bearings, housings, gears, lubricants, spacers and springs. A bearing selection dialogue enables the selection of bearings from the SKF catalogue. The rolling bearings database is updated on a regular basis.

Operating conditions such as speed, loads, lubrication and fits of shaft and housing are added to the application model. The load and speed conditions can be entered as a combined load cycle.

Once the customer has built the model he or she is presented with a choice to run a single load analysis or a full load cycle analysis, depending on machine operating conditions. In addition, a bearing preload optimisation analysis can be performed.

SKF SimPro Quick provides calculation results with a comprehensive range of useful performance output parameters such as bearing fatigue life, bearing load, loaded zone, contact stress, bearing displacement and misalignment, friction, bearing defect frequencies and shaft deflection. The output can be viewed in various graphical charts and in a 3D model. A report is created automatically, based on selected output results and is conveniently exportable in pdf, doc and html formats. Get registered at www.skf.com/skfsimpro

For more information contact Samantha Joubert, SKF South Africa, +27 (0)11 821 3500, [email protected], www.skf.com

| Tel: | +27 11 821 3500 |

| Email: | [email protected] |

| www: | www.skf.co.za |

| Articles: | More information and articles about SKF South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved