Yokogawa Electric has announced Synaptic Business Automation, a new industrial automation and control business concept that expresses the company’s commitment to working with its customers to sustain their creation of corporate value.

A closer look at Synaptic Business Automation

Manufacturers face a variety of challenges today, ranging from volatile shifts in the prices of crude oil and other raw materials and stiffening environmental and safety regulations to structural changes in their industries. To remain competitive, they must have the ability to adapt quickly to change.

To guide its efforts to assist companies in meeting such challenges, Yokogawa adheres to a vision statement that reads, “Through ‘Process Co-Innovation,’ Yokogawa creates new value with its clients for a brighter future.” We help companies improve efficiency and profitability by getting their various business units to work together more effectively and by eliminating barriers that impede the flow of information and goods throughout the supply chain and between companies.

As the Internet of Things gains traction, a digitalisation of processes is underway whereby the use of big data and artificial intelligence is yielding valuable insights needed to make business decisions. The Synaptic Business Automation concept clearly expresses Yokogawa’s commitment to using the latest information technologies and its decades of experience with plant management and industrial processes, portfolio of automation solutions, and consulting expertise to help its customers transform their businesses.

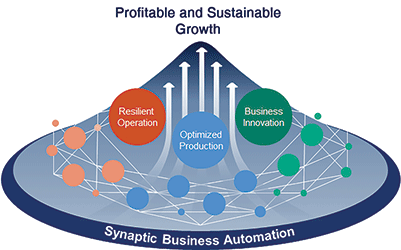

The Synaptic Business Automation concept takes its name from the synapse, a structure in the nervous system that plays a role in the transfer of signals to other parts of the body. Synaptic Business Automation expresses an ideal state for a business whereby the synthesising of data, systems, organisations, knowledge, and supply chains adds value and strengthens competitiveness. The linked data on manufacturing processes, plant operations, human resources, and supply chains can be organised, integrated, controlled, broken down, and analysed to yield insightful decisions at various levels in the organisation, from operations in the field to corporate management.

Ways in which Synaptic Business Automation creates corporate value for customers:

1. Resilient operation

Adapt more flexibly to changes in such areas as health, safety, security and the environment (HSSE), organisational optimisation, and regulatory compliance.

2. Optimised production

Optimise the total expenditure (TOTEX) components of capital expenditure (CAPEX) and operational expenditure (OPEX) over the entire lifecycle of a plant, and improve reliability. Also, directly create value by solving issues and optimising operations throughout a supply chain, thereby enhancing productivity and profitability.

3. Business innovation

Work with specific customers to create new business models that foster manufacturing excellence by such means as supplying cloud-based services that drive collaboration with their customers and suppliers and to introduce environmentally friendly manufacturing practices that are essential for a sustainable society.

Yokogawa has many years of experience in working with operationaltechnology (OT). By combining its in-depth knowledge of plant management, operations, industries, and processes, its portfolio of automation andother information technology solutions, and its consulting expertise, the company is uniquely positioned to create new value. Working together with its customers based on the ‘Co-innovating tomorrow’ corporate brand slogan, Yokogawa is committed to helping them achieve the ideals expressed in its Synaptic Business Automation concept.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved