Karl Steinbuch was one of the pioneers of computer science, a trailblazer of machine learning and a co-founder of artificial intelligence. In 1966, he put forth his vision: “In a few decades computers will be interwoven into almost every industrial product.” We now know that he was right.

In 1980, computers began being designed for home use, the World Wide Web was developed in 1989 and not much later the world’s first website was published. Then, more and more computers were linked, computer technology became ubiquitous and now we are in the midst of global digitisation.

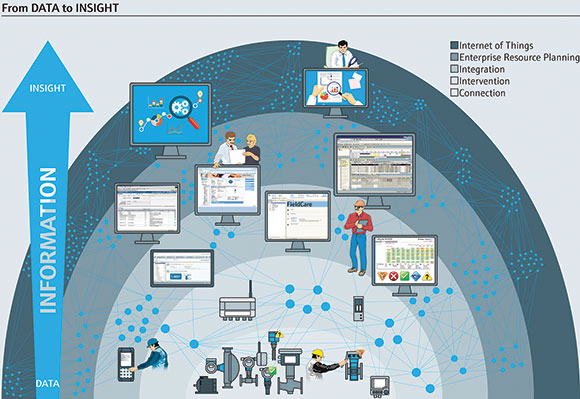

Thanks to the continuous progress of microelectronics and information and communications technology, objects that are used daily are now capable of being linked with each other for data sharing purposes. Traditional objects, such as household appliances, smartphones and vehicles are ‘digitally equipped’ with microcontrollers and software. ICT capabilities are constantly being added to them, a development that generates added value for devices and services and provides new opportunities for business and personal life. This is the IoT and it provides relevant information in real time through connective networking of products, devices and processes that generate data.

What significance does the IoT have for the business sectors of Endress+Hauser in liquid analysis?

It is not hard to recognise that continuous measuring systems yield an enormous quantity of data over time, particularly when a process involves several measuring points and each measuring point is equipped with numerous measuring instruments. However, practice shows that only a fraction of this information can actually be used, an insight which indicates the great potential for future IoT applications in process automation.

Components of the IoT include a measuring system with continuous self-monitoring, methods for automated data analysis, tools for simple display of complex process information, and mobile end devices, cloud technologies and new service concepts.

When these are linked, they provide users with new opportunities to increase operational performance factors, such as system efficiency, process stability and operational safety. These technologies play a significant role in areas such as water management. In terms of digitisation, this includes associated topic areas related to the IoT, such as Water 4.0, Water management 4.0, Big Data and cyber-physical systems.

Intelligent measuring systems for the water supply of tomorrow

The objective of the project ‘Intelligent measurement methods for process optimisation of the supply and distribution of drinking water’ (IMProvT) is to develop IoT solutions for optimising the water supply.

The Federal Ministry of Economic Affairs and Energy (BMWi) in Germany is promoting this project as part of the energy research programme. The project is headed by the Technical University of Cologne and, in addition to Endress+Hauser Conducta, the project partners includes various long-distance water suppliers, water utility companies, associations for drinking water, water centres, technical and scientific associations. One of the long-distance water suppliers provided three measuring points that are equipped with multi-parameter measuring stations from Endress+Hauser. The measurement data is transmitted to a central server at the Technical University of Cologne and analysed there using mathematical models.

The objective is to identify parameter samples that can be used to detect typical operating statuses in the long-distance water supply system. This should help plant workers anticipate the effects of possible malfunctions and make it easier to plan countermeasures. In addition, suitable data networking methods are being developed to optimise or avoid flushing segments of the water supply system with fresh water, which is both costly and resource-intensive.

Another project task is the development of methods for plausibility checks of measurement data, and for data cleansing. From the perspective of water suppliers, corresponding software tools are necessary to improve the quality of process data and create a reliable basis for further evaluation methods using automated actions.

In addition to instrumentation and consultation during operation, Endress+Hauser Conducta is responsible for strategic management of the project. This central role ensures that the developments are aligned with customer needs and technological requirements, and that new opportunities for value creation are identified.

For more information contact Hennie Pretorius, Endress+Hauser, +27 (0)11 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved