Pure power packaged perfectly

May 2017

Motion Control & Drives

LSIS is committed to the future of smart energy. With its tradition of going the extra mile when designing and building equipment, this Korean manufacturer of automation and drive systems is a force to be contended with especially when it comes to the medium voltage drives offering.

The LSMV-M1000 is worth every penny from the innovative design and packaging to the energy savings on implementation. It also boasts some key features that make it one of the market leaders in this sector.

Starting with an all-in-one system, the M1000 caters for 3,3 kV-13,8 kV with combinations of output voltage available. For example, a 6,6 kV motor can be run off a 13,8 kV supply with LSIS flexible input/output voltage ranges.

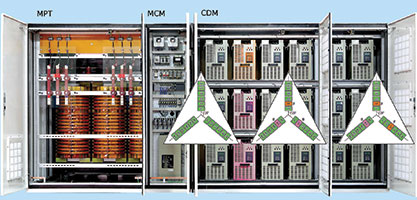

The M1000 has a built-in ‘multi-winding phase-shift’ transformer (36 pulse/18 winding) with taps to accommodate variations in input voltage. This also helps to eliminate the need for chokes and filters and by extension allows for greater distances between motors and drives. The order options for the transformers are offered as either built into the drive or standalone air or oil cooled variations.

The ‘Master Control Module’ manages the multi-level PWM output voltage, the power cells and fibre optic communication, using the LSIS-XGi plc for control, the LSIS-XP80 HMI and the LSLV-iG5A inverters for the cooling system control, which are all available off the shelf in South Africa.

The ‘Cell Drive Module’ utilises six low voltage single-phase drives connected in series per phase. This generates multilevel 3-phase output voltage. The configuration is known as the cascaded H-bridge multi-level drive. This results in capabilities such as flying start, ride through of up to 5 cycles, anti-current hunt algorithms and sensorless vector torque control to mention a few.

Additionally, the transformers are shielded from the MCM and CDM thus eliminating the effects of power spikes or lightning strikes from either interrupting or destroying these two critical systems.

Each cell has its own IGBT and control card thus allowing for cell protection and bypass. For example should U2-phase cell fail its control card bypasses it and the control system automatically bypasses the corresponding V2 and W2 cells thus balancing the output phases. Shutdown time is cut down to a minimum as the offending cell is simply replaced from the front by loosening its bus connections behind it, pulling the defective cell out and inserting the new cell in its place, then reconnecting its bus and powering the system up.

The LSMV-M1000 is also aesthetically pleasing and adds an air of professionalism and dignity to the installation. Thus when it comes to weighing up the options this one stop drive is a definite option in its class, a credit to the LSIS brand and an asset to any installation.

Further reading:

Novel bearing steel next generation of aeroengines

SKF South Africa

Motion Control & Drives

SKF continues to re-imagine intelligent and clean rotation with the development of an innovative temperature-resistant, corrosion-tolerant steel called ARCTIC15 designed for aeroengine bearings.

Read more...

Products from maxon

Motion Control & Drives

A wide range of new products is available from motion control specialist, maxon. with a diverse technology portfolio ranging from highly integrated robotic actuators to powerful servo drives and controllers.

Read more...

Actuators for precise hexapod movements

Motion Control & Drives

Aerotech, manufacturer of high-performance motion control and automation systems, is expanding its Automation1 platform. These compact hexapod devices enable the complete integration of six-axis motion systems into existing control

Read more...

SEW-EURODRIVE service centre transforms future of drive repairs

SEW-EURODRIVE

Motion Control & Drives

In a momentous step for the local industrial gearbox and drives market, SEW-EURODRIVE South Africa has formally opened a new service and repair facility alongside its headquarters in Aeroton,

Read more...

Strategic system upgrades beat mining obsolescence and drive productivity

Motion Control & Drives

Mining operations are under constant pressure to maintain output while controlling costs. One persistent challenge continues to confront the industry, knowing when and how to upgrade aging systems before they become a liability.

Read more...

Precision meets performance: The ELGD Axes Family from Festo

Festo South Africa

Motion Control & Drives

Festo has introduced the ELGD axes family, engineered for the demands of future-focused industries. With cutting-edge guide technology, exceptional rigidity and high load capacity, these axes deliver more performance within the same installation footprint.

Read more...

Condition monitoring in hazardous areas

SKF South Africa

Motion Control & Drives

SKF is further strengthening its condition monitoring offer portfolio by a newly developed hazardous area version of its Microlog Analyzer dBX portable vibration analyser.

Read more...

Rip-and-ship solution speeds up nuclear decommissioning project

Motion Control & Drives

When removing steam generators from decommissioned nuclear reactor buildings, the most economical method is to remove them in one piece. Mammoet was commissioned by Framatome to support with the removal of four steam generators from PreussenElektra’s Nuclear Power Plant Unterweser in Germany.

Read more...

WearCheck turns the focus on friction modifiers

Wearcheck

Motion Control & Drives

One of the most important features of a lubricant is the reduction of friction between two surfaces.A dditives like friction modifiers are added to perform this function. Wearcheck turns the focus on friction modifiers

Read more...

SEW-EURODRIVE transforms drivetrain uptime

SEW-EURODRIVE

Editor's Choice Motion Control & Drives

The DriveRadar IoT Suite from SEW-Eurodrive is an ideal solution for industrial condition monitoring. This powerful ecosystem of intelligent sensors, edge devices and cloud-based analytics ensures that customers have full visibility and control of their operations.

Read more...