Rockwell Automation has announced a new app, FactoryTalk TeamONE, for iOS and Android smartphones. As part of the company’s expanded Information Solutions strategy to help employees make better decisions across their enterprise, the app seamlessly connects to the technology that manufacturers adopt during their digital transformation. The app boosts team productivity by enabling users to collaborate and share knowledge, view live production diagnostics, interact with machine alarms, and troubleshoot devices. Teams that use the FactoryTalk TeamONE app could drive a reduction in mean time to repair (MTTR).

Incident data in real-time

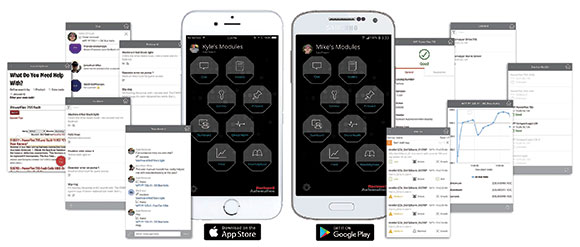

By offering near instantaneous incident and device data, plant floor, engineering and IT workers can collaborate more effectively as a team to solve problems. From their smartphone, employees can choose from the variety of modules with the FactoryTalk TeamONE app to view information from devices, such as Allen-Bradley PowerFlex drives, or see the high-level health status of any EtherNet/IP device. This information is shareable across the app’s collaboration and troubleshooting modules with other trusted team members. Once issues are resolved, learning can then be flagged, saved and searched for the next time an incident arises.

“Industrial companies usually spend years and make significant capital investments in new technology to view data from machines before they even begin to see it pay off through productivity gains,” said Christo Buys, business manager for control systems, Rockwell Automation sub-Saharan Africa. “The “FactoryTalk TeamONE app introduces a new, value paradigm where individuals can download the app, form a team and use their knowledge alongside device data to drive productivity increases. The app doesn’t need teams to install servers, have pre-existing infrastructure like OPC servers, or connect automation assets and devices to the cloud in order to use the modules.”

The FactoryTalk TeamONE app is a smart node. Rather than act as a client that connects to a server, the app’s device modules communicate directly to devices on the network for live data viewing. When secure cloud access is available, the modules sync with other trusted team members.

The initial release, known as the FactoryTalk TeamONE Free Edition, is available now and includes eight modules: Incident, Device Health, Teamboard, Knowledgebase, Connect, Pinboard and Chat, Connect and Trend. It can be downloaded off the Google Play or Apple app stores. In the future, FactoryTalk TeamONE Standard Edition will be offered on a yearly user-based subscription. It will provide an additional alarms module, multiple team logins and other features as customer feedback is compiled. Teams with a mix of free and subscription versions are not hindered from seamlessly collaborating.

“We view FactoryTalk TeamONE as the first app focused solely on increasing industrial worker productivity by converging team collaboration and automation-centric data,” said Buys. “It’s a really exciting, innovative space where we’re planning to update often. In fact, we’re already planning for future modules, integration with FactoryTalk Analytics applications, and even contributed content.”

The app was previewed with over 500 customers since September 2016. It was developed closely with Microsoft by using a lean start-up team previously known as ‘Project Stanton’.

For more information contact Christo Buys, Rockwell Automation, +27 (0)11 654 9700, [email protected], www.rockwellautomation.co.za

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved