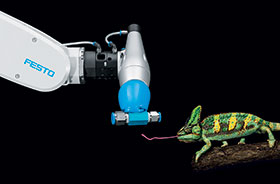

Gripping applications have always played a key role in production and Festo is constantly on the lookout for new gripping principles and innovative approaches to production systems in the factory of tomorrow. Using nature as a model, Festo has now developed a gripper whose working principle is derived from the tongue of a chameleon, in cooperation with the Oslo and Akershus University College of Applied Sciences,

The FlexShapeGripper can pick up, gather and set back down several objects with the widest range of shapes in one procedure – without the need for a manual conversion. This is made possible by its water-filled silicone cap, which wraps itself around the items being gripped in a flexible and form-fitting manner.

Nature as a model

In nature, the unique combination of force and form fit demonstrated by the tongue can be observed when the chameleon is on the hunt for insects. Once the chameleon has its prey in its sights, it lets its tongue shoot out like a rubber band. Just before the tip of the tongue reaches the insect it retracts in the middle, whilst the edges continue to move forwards. This allows the tongue to adapt to the shape and size of the prey and firmly enclose it. The prey sticks to the tongue and is pulled in like a fishing line.

A double-acting cylinder

The gripper consists of a double-acting cylinder where one chamber is filled with compressed air whilst the second one is permanently filled with water. This second chamber is fitted with elastic silicone moulding, which models the chameleon’s tongue. The volume of the two chambers is designed so that the deformation of the silicone part is compensated. The piston, which closely separates the two chambers from each other, is fastened with a thin rod on the inside of the silicone cap.

Form-fitting gripping through inversion

During the gripping procedure, a handling system guides the gripper across the object so that it touches the article with its silicone cap. The top pressurised chamber is then vented. The piston moves upwards by means of a spring support and the water-filled silicone part pulls itself inwards. Simultaneously, the handling system guides the gripper further across the object. In doing so, the silicone cap wraps itself around the object to be gripped, which can be of any shape, resulting in a tight form fit. The elastic silicone allows a precise adaptation to a wide range of different geometries. The high static friction of the material generates a strong holding force. Both the holding and the release mechanism are triggered pneumatically. No additional energy is necessary for the holding process.

The yielding quality of the compressible compressed air simplifies the coordination between the handling system and gripper during the grip stage. The force and the deformation of the silicone part can be set very precisely with the aid of a proportional valve. This allows several parts to be gripped at once in a single procedure.

Flexible systems

In future, the FlexShapeGripper could be used in any facility where multiple objects with a range of different shapes are handled at the same time – for example in the service robotics sector, for assembly tasks or when handling small parts. In flexible production plants, it would be possible to handle all kinds of products in one procedure, without having to change the gripper.

In today’s industrial automation environment there are many different grippers, each developed for a special task. If the shape of a workpiece changes, the corresponding gripper must be replaced on the machine or converted, which requires a great deal of effort. In facilities that make a range of products, changeover systems are therefore used, which are fitted with different grippers. In the factory of the future, however, there will be a need for more flexible systems, which are independently adjusted to each product being made. Adaptable grippers like the FlexShapeGripper can assume a significant role in this respect.

Festo’s Bionic Learning Network aims not only to learn from nature, but also to identify good ideas at an early stage and foster them jointly beyond company borders. The project shows how Festo applies principles from nature to its core business of automation and how important the interdisciplinary exchange of information is beyond company borders. The gripper is an outstanding example of the close collaboration by Festo with international universities as part of this network.

The full story can be found at http://instrumentation.co.za/+J932

For more information contact Kershia Beharie, Festo, +27 (0)11 971 5509, [email protected], www.festo.co.za

| Email: | [email protected] |

| www: | www.festo.co.za |

| Articles: | More information and articles about Festo South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved