OEMs are increasingly using industrial networks to connect their HMIs, controllers, distributed I/O, instruments and sensors to each other within a machine or a robot. As a consequence, Ethernet is quickly becoming the network of choice for robot and machine builders OEMs and their customers. In addition, automation components suppliers are including Ethernet and IP connectivity on more and more of their devices, creating an ever expanding circle of Ethernet usage.

Why Ethernet?

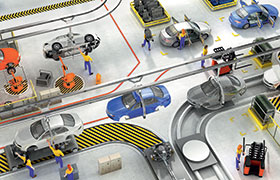

Even the simplest of today’s production lines include a wide range of different machines and robots, most often supplied by a number of OEMs. Adding to the complexity is the fact that most machines and robots contain a number of automation components such as HMIs, controllers, motor drives, instruments and sensors. All of these components need to communicate not only with each other within a machine or robot, but often with other machines and robots to closely coordinate and optimise production. Two-way communication is also required among machines, robots, and customer control and communication systems. Fortunately, many Ethernet-friendly standards and protocols exist to simplify these communications. These include ISA-88/PackML (batch and control), ISA-95 (data integration) and ISA-99 (security).

Using standard Ethernet and common protocols as well as the abovementioned standards also makes it possible for each machine in an assembly line to communicate with the next unit in the line regarding its status and utilisation. If each piece of equipment in one or more assembly operations knows the status of its neighbours, it’s possible to make maximum use of each machine to optimise throughput across the facility by synchronising machine inputs and outputs.

Why industrial?

Because any system is only as good as the physical infrastructure on which it’s built, it’s imperative that the equipment chosen for the application is specifically designed for the environment in which it will be used. Industrial temperature ranges can cover the spectrum from -40 to greater than 70°C. Industrial plants also have many sources of EMI/RFI interference, including large power cables, big motors and other equipment such as robot welders. In addition equipment needs to be protected from humidity and moisture by specifying NEMA 4 or IP67 protection. It must also be able to withstand vibration covering a broad range of frequencies and amplitudes; and assembly lines incorporate a large number of moving parts such as robot arms, conveyors, and pick and place systems.

Just as important as selecting the right industrial grade components are the connections among the components. In the case of Ethernet, these connections are typically Cat 5e or Cat 6 cable. Physical cable integrity and electrical performance must be maintained or deterioration of the signals will lead to failure of the network.

Many machines and robots continually place Ethernet communication cables under duress by movement and the consequent cable flexing. Flex cycles cause stress on cables and connections, often resulting in premature failure. Data integrity can also be compromised because of changes to cables during these flexing operations, with the resulting risk that data communication interruptions will occur.

Fortunately, high flex industrial Ethernet cables are available that can operate reliably in continuous flex environments without signal interruption. These special cables are normally used to implement Ethernet on robots and machines with these types of requirements. As with industrial grade Ethernet components, upfront costs are somewhat higher for high flex as compared to standard cables, but the extra expense is well worth it to guarantee reliability at an acceptable level.

Ethernet is quickly becoming the standard in industrial settings. But because the plant environment isn’t the same as the office, both the design and the components must be appropriate for the task at hand. Extra cost spent up front to purchase industrially rated components and employ proper design expertise will be more than repaid over the life of the network in terms of more uptime and greater throughput of the manufacturing process.

© Technews Publishing (Pty) Ltd | All Rights Reserved