To extract raw sugar juice, the mill first crushes, shreds, or presses the cane or beets. The raw juice that is extracted is highly pure, but contains undesirable organic and inorganic non-sugar constituents, along with colour. At this stage, the mill may add formalin or other antibacterial agents to the recycled press water to inhibit bacterial growth.

The next steps, pre-carbonation and liming, act to purify the raw juice. During purification, insoluble solids, gums, polysaccharides, and dissolved colorants coagulate out for removal by settling and filtration.

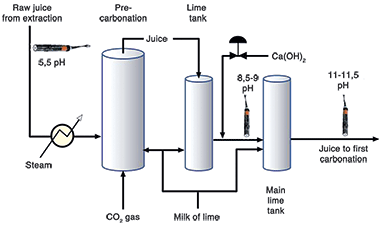

Mills purify the juice using lime and carbonic acid. To create lime the mill heats limestone (calcium carbonate) in kilns to produce burnt lime (calcium oxide) and carbon dioxide. The end product is mixed with water, becoming milk of lime (whitish lime particles suspended in water) and the carbon dioxide introduced to the pre-carbonation tank mixes with water to become carbonic acid.

Cane processors practice partial liming while beet processors apply complete liming. The goal of complete liming is to reduce invert sugar (glucose and fructose) as much as possible by adding an excessive amount of lime. Cane processors partially destroy the invert sugars, using less lime. Some refiners use a combined purification process consisting of phosphoric acid and lime by which 30-37% of the syrup colour is removed.

The raw juice from extraction is acidic with a pH of about 5,5 – usually controlled by the addition of sulphur dioxide. Before entering the pre-carbonation tank, the juice is heated to a temperature of 76-82°C. The additions of milk of lime and carbon dioxide in the pre-carbonation step begin to raise the juice pH. The chemical addition has three desirable effects:

• The high pH prevents the sugar from becoming starch or reverting to non-sucrose forms.

• Organic acids are changed into salts for later removal by precipitation.

• Foreign matter is kept in suspension for removal by filtration.

On leaving the initial lime tank, the juice pH has been raised to a value near 9. Continued addition of milk of lime in the main liming tank raises the pH to 11 or more. From this point the juice travels to the first carbonation step to remove excess lime and filter out precipitates.

Challenges in measuring pH

Sugar refining is a high-temperature, caustic process requiring tight pH control in almost every stage. Because the process is so physically demanding, in the past pH measurement was typically made in cooled sample lines (introducing significant lag time) or via grab samples (even longer lag time).

Attempting to control a nonlinear variable such as pH in a continuous, dynamic process using these methods can easily lead to loss of process control. Prior to improvements in both pH glass and reference technology, online measurements were virtually impossible. Excursions of pH regularly occurred, and shutdowns were common.

The ABB Solution: TBX551 and TBX587 pH sensors

Most sugar mills will operate through a growing season (referred to as a ‘campaign’). The campaign will last 3-6 months, depending if beet or cane sugar is being refined. If the pH sensor can last through the entire campaign then this is considered to be a success.

The largest obstacle in controlling pH in the sugar mill is finding equipment that will tolerate the harsh conditions found in this environment. Lime addition takes place before any filtration, introducing precipitation and coating issues. The temperature of the process after pre-carbonation is typically greater than 80°C, and finally, many mills do not have the extensive instrumentation staff that other industries have, and so lack education on cleaning and calibration of the pH sensor.

For these applications, ABB’s Twist Lock TB(X)551 is ideal for sample line installations. The bayonet style mounting makes sensor removal for cleaning and calibration very easy. If the pH sensor is inserted directly into the process, then ABB recommends a retractable sensor with extraction housing. The housing has flushing ports which can be used to loosen congealed sugar and particulates. The TB(X)587 or TB(X)557 are good examples of retractable sensors that work in these processes. For all liming applications the coat resistant 'J' Glass electrodes should be specified. The Wood Next Step Reference can be used for the applications below 11 pH and PTFE can be specified above 11 pH.

For more information contact ABB South Africa, +27 (0)10 202 5000, [email protected], www.abb.com/measurement

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved