Topics covered were: a potted history of commercial nuclear power; important concepts to commercial nuclear power; ‘passive’ and active safety; reactor protection systems.

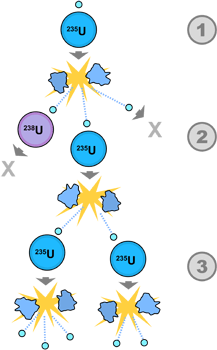

On the 2nd of December 1942 the first nuclear reactor sustained a chain reaction. It had ‘control rods’ that controlled the reaction rate or stopped the reaction. A rope and pulley held the control rods in position and a man was given an axe and told that if something went wrong he should cut the rope, letting the rods fall rapidly down into the reactor. He was later called the Safety Control Rod Axe Man, and the term SCRAM and control rods are still used today.

In the 1950s the first nuclear power generation stations were built and in 1954 we had the first nuclear powered submarine. By 1960, 1 GW of nuclear power was being produced, 100 GW in the late 1970s and 300 GW in the late 1980s (Wikipedia).

Koeberg, presently the only nuclear power plant in Africa, started commercial power production in 1984 and produces 1.9 GW from two units. Koeberg has produced 360 036 GW.h to date. (We pay for electricity in kW.h, so Koeberg has produced 360 x 109 kW.h.

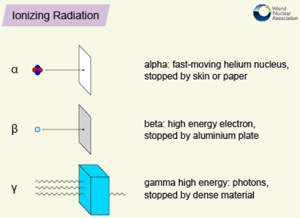

Contamination and Radiation

Contamination is radioactive particles that can be solid, liquid, dust or gas. Contamination can damage a person’s skin or even cause deeper damage sometimes. If breathed in or swallowed, contamination can cause much internal damage.

Radiation flies through the air and has energy that can damage whatever it strikes.

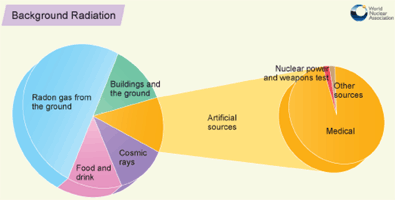

There is natural background radiation everywhere in the world:

The background radiation at Koeberg (including working reactors) is about a quarter of the background radiation in a place like Paarl that has granite rocks in the ground.

Nuclear power plants around the world, including Koeberg, are most concerned about preventing radiation releases that could affect the public, and go to immense expense and effort to ensure that this never occurs. Related to this, with similar expense and effort, they ensure that staff do not get radiated or contaminated above internationally agreed limits.

The ‘Linear’ radiation model adopted in the 1930s says that any amount of radiation can cause lasting damage to people. Medical and other experience has shown that the ‘Threshold’ model is more accurate and that radiation below certain thresholds cannot cause lasting damage.

Fusion and Fission are the two types of nuclear power. Fusion reactors will, if they ever achieve commercial operation, produce more power and less radioactive waste than current commercial fission reactors. In fusion (research) reactors, light atoms (hydrogen, helium etc.) are forced by high thermal energy (temperatures in the region of 11 million °C) to fuse together to create bigger atoms and release even more energy than it took to fuse them.

Fission consists of the splitting (fissioning) of large atoms such as uranium by striking them with lower energy ‘thermal’ neutrons. A fissioned uranium atom releases gamma rays and radioactive particles, including neutrons, which are used to fission more uranium atoms – this is a chain reaction.

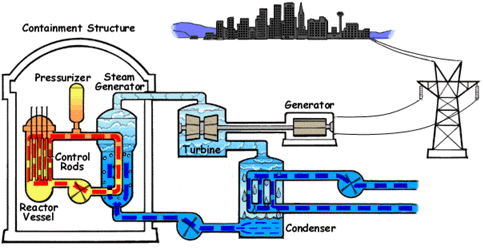

There are various types of nuclear reactor. Many reactors currently producing power are pressurised water reactors, such as Koeberg, in which the water that cools the reactor is in the primary closed circuit.

Heat is transferred to a secondary closed circuit by a heat exchanger, keeping any contamination in the primary circuit. The heat exchanger, or steam generator, boils the secondary water and the steam drives the turbine to produce power. The steam exhausted by the turbine is condensed back to water for recirculation. The heat exchanging condenser is cooled by river or sea water. The containment structure seals its contents from the atmosphere and at Koeberg it consists of 1 m thick concrete with a thick steel inner lining.

‘Passive’ safety features do not require controlled or powered actions to perform their function, for example:

• the pressurised primary circuit is robustly designed to remain intact and safe for at least 40 years, with many plants extending to 60 years.

• accumulators are filled with water and pressurised with nitrogen. They have non-return valves so that if the primary system loses pressure, their liquid content is injected into the reactor and primary system.

For Active safety features, plant parameters are measured, with redundancy for reliability of safety signals and further redundancy for failures and testing. Most parameters, e.g. reactor water temperature, have three measurements and more important ones have four measurements, such as containment pressure. Safety signals are sent to two trains of safety actuators that perform safety functions when needed, e.g. reactor trip (SCRAM).

Reactor protection system

Important aspects of the reactor protection system channels and trains are redundancy, fail-safe, independence (one cannot be influenced by the other), isolation (cannot be influenced by connected systems), insulation (separate power sources) and separation (flooding or fire affecting one cannot affect the other). Power supplies are battery backed and have a separate backup (non-battery).

Signal Processing consists of signal conversion, filtering, function generation, multiplication, summing, square root, set-value and set-point (threshold) functions. For each plant parameter that is measured there are two, three or four redundant channels. Each ends as a reactor protection logic signal.

Logic processing comprises two identical, redundant trains, with further internal redundancy for on-line repairs and testing. The logic trains consist of voting gates: one-out-of-two (1oo2), 2oo3 and 2oo4; and logic combination of various signals to produce safety actuation signals.

Plant safety actuations also consist of two redundant trains, with two of each actuator. Actuators are pumps, valves, motor operated valves, circuit breakers, pneumatic controllers etc.

The fail-safe design of all reactor protection equipment means that failures can never prevent a safety signal from being transmitted, although this can be the cause of unnecessary safety signals and reduce production reliability. Every reactor protection system component is tested every two or three months and is kept qualified for its function (e.g. regular replacement of sensor O-rings) to ensure reliability of safety signals.

© Technews Publishing (Pty) Ltd | All Rights Reserved