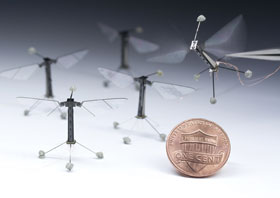

Harvard researchers have demonstrated the first controlled flight of an insect-sized robot. Half the size of a paperclip and weighing less than a tenth of a gram, it can leap a few inches, hover for a moment on fragile, flapping wings, and then speed along a preset route through the air.

With two wafer-thin wings that flap almost invisibly, 120 times per second, the tiny device represents the absolute cutting edge of micro manufacturing and control systems. Flight muscles, for instance, don’t come pre-packaged for robots the size of a fingertip. “Large robots can run on electromagnetic motors, but at this small scale you have to come up with an alternative,” says Professor Robert Wood, principal investigator at Harvard’s School of Engineering and Applied Sciences (SEAS).

Flies are among the most agile flying creatures on earth. To mimic this aerial prowess in a similarly sized robot required tiny, high-efficiency mechanical components that posed miniaturisation challenges requiring unconventional solutions for propulsion, actuation, and manufacturing. Other researchers have built robots that mimic insects, but this is the first two-winged robot built on such a small scale that can take off using the same motions as a real fly. The dynamics of such flight are very complicated.

The researchers achieved this wing speed with special high-power density piezoelectric actuators – strips of ceramic that contract and release when power is switched on and off. By constantly adjusting the effect of lift and thrust acting on its body at an incredibly high speed, the robot’s flapping wings enable it to hover almost motionless in the air or perform sudden evasive manoeuvres. Thin hinges of plastic, embedded within the carbon fibre body frame, serve as joints, and a delicately balanced control system commands the rotational motions in the flapping wings, with each wing controlled independently in real time. At tiny scales, small changes in airflow can have an outsized effect on flight dynamics, and the control system has to react that much faster to remain stable.

The Robo-fly also takes advantage of an ingenious pop-up manufacturing technique that was developed by Wood’s team in 2011. Sheets of various laser-cut materials are layered and sandwiched together into a thin, flat plate that folds up like a child’s pop-up book into the complete electromechanical structure. The quick, step-by-step process replaces what used to be a painstaking manual art and allows Wood’s team to use more robust materials in new combinations, while improving the overall precision of each device.

“Applications of the project could include distributed environmental monitoring, search-and-rescue operations, or assistance with crop pollination, but the materials, fabrication techniques, and components that emerge along the way might prove to be even more significant,” says co-lead author Kevin Ma, a graduate student at SEAS.

The prototypes are still tethered by a very thin power cable because there are no off-the-shelf solutions for energy storage that are small enough to be mounted on the robot’s body. High energy-density fuel cells must be developed before the Robo-fly will be able to fly with independence. The next steps will involve integrating the parallel work of many different research teams who are working on the brain, the colony co-ordination behaviour and the power source until the robotic insects are fully autonomous and wireless.

“This work is a beautiful example of how bringing together scientists and engineers from multiple disciplines to carry out research inspired by nature and focused on translation can lead to major technical breakthroughs,” says Wood. “This project provides a common motivation for scientists and engineers across the university to build smaller batteries, to design more efficient control systems, and to create stronger, more lightweight materials,” he adds. “I want to create something the world has never seen before,” continues Ma. “It’s about the excitement of pushing the limits of what we think we can do – the limits of human ingenuity.”

For more information visit http://tinyurl.com/qbwtqfd

© Technews Publishing (Pty) Ltd | All Rights Reserved