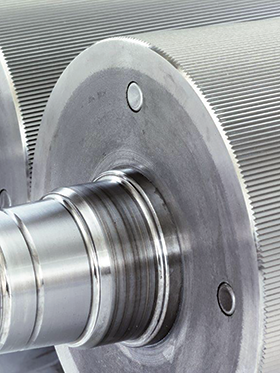

Bühler has reinforced its commitment to customers in southern Africa with the installation of a new die refurbishment machine at its Johannesburg workshop. The investment enhances Bühler’s regional service offering by improving precision, shortening turnaround times and supporting sustainability goals.

Daniela Supra, head of customer service operations at Bühler, says: “We are continuously investing in our local capabilities to ensure our customers receive world-class service with local speed and responsiveness. The addition of the new die refurbishment machine at our Johannesburg workshop is part of our ongoing commitment to offering reliable, high-quality and cost-effective services.”

The new equipment increases capacity, ensures improved quality assurance and reduces the risk of downtime for customers provided the refurbished die is kept on site. It also offers a one-stop solution to optimise die life, reduce energy consumption and improve product quality. Supra adds that technical assistance from experienced service engineers ensures customers get the most out of their plant.

Bühler operates three workshops across southern Africa, all aligned with the company’s global quality standards. Both Johannesburg and Cape Town are ISO 9001 certified. Johannesburg offers a full suite of refurbishment services, including milling, oil and brewing rolls, die refurbishment and mechanical repairs. Cape Town specialises in mechanical servicing and roll and die reconditioning, and is expanding its machine refurbishment capabilities. The Lusaka, Zambia workshop provides onsite mechanical services, roll refurbishment and logistics support to reduce lead times and import dependency, with the goal of achieving ISO 9001 certification before the end of 2026.

“All workshops are strategically positioned and equipped to meet the specific needs of their regional markets and are capable of full-scale retrofits,” explains Supra. Bühler also offers service agreements designed to give customers peace of mind and predictable maintenance planning. Inspect Care offers regular inspections to detect issues early, while Maintain Care comprises scheduled maintenance, component replacement and performance checks at a fixed cost.

“Both options help customers extend equipment lifetime and reduce the total cost of ownership,” says Supra. “We see service not as an add-on, but as a key part of how we build trust and long-term partnerships.”

Another critical input is customer feedback, which is at the heart of the service development. “Whether it is through structured surveys, face-to-face discussions or post-service reviews, we actively listen and act. Many of our service innovations, including expanded regional coverage and contract offerings, are directly structured by customer input,” notes Supra. Field service engineers are strategically located across southern Africa and trained in both mechanical and electrical disciplines. They provide installation support, breakdown repairs, maintenance services, plant audits and training. This ensures rapid onsite support and strong customer engagement wherever it is needed.

Remote support is also becoming increasingly important. With BühlerVision, an augmented reality-based support solution, customers can connect to Bühler experts worldwide through Smart Glasses. “The expert sees what the technician sees in real time, guiding them step-by-step through diagnostics or repairs. It saves time, reduces travel costs and ensures expert-level service instantly,” comments Supra. She stresses the importance of investing in local capacity. “Our ISO-certified workshops ensure global quality with local relevance. This also supports local job creation and skills development, reinforcing our long-term commitment to the region.”

Bühler plans to expand its regional footprint, upskill more technicians and continue investing in smart technologies such as Bühler Vision and condition monitoring systems. “Our goal is to make service more predictive, responsive and accessible for every customer across the region,” concludes Supra.

For more information contact Taryn Browne, Bühler Southern Africa,

© Technews Publishing (Pty) Ltd | All Rights Reserved