New Zealand has been at the forefront of technological development in agriculture for years. A recent example involves the use of SNPshot DNA tests, which harness the latest technology – including from Beckhoff – to meet the needs of two end user groups: farmers who take samples in the field, and DNA laboratories that process the resulting samples.

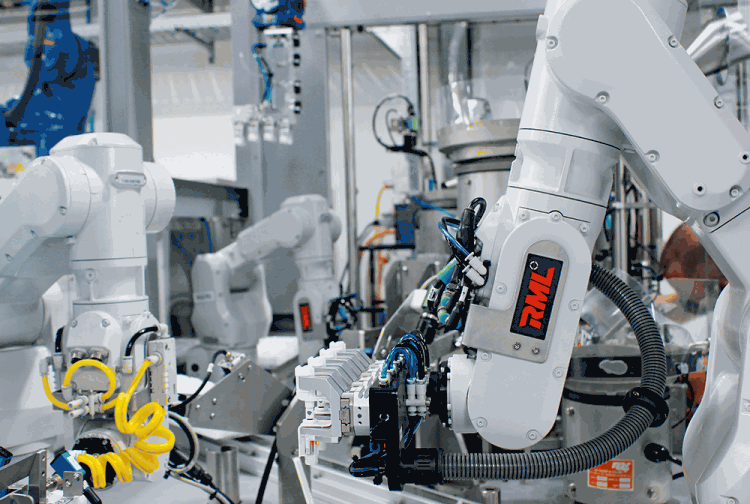

New Zealand-based automation and robotics company, RML Machinery has worked closely with Beckhoff on control system integration for the last decade. RML provides comprehensive solutions for many of Australia’s leading FMCG brands, implementing the flexible ‘challenge accepted’ approach to automation technology. The progressive, flexible and reliable approach of Beckhoff makes it the ideal partner for RML, which is always thinking one step ahead in terms of increasingly sophisticated solutions.

High-precision DNA sampling on the farm

Around 15 million SNPshot DNA tests samples are taken worldwide every year to identify stud horses, sheep, farmed salmon, and more. The SNPshot DNA sampler is equipped with both RFID and barcode readers, capable of reading a wide variety of animal ID tags. At the time of sampling, the GPS coordinates of the sampling site are recorded, to be used as a practical verification and risk management tool.

The sampler reads an animal’s ear tag and links it to a QR code on the corresponding cartridge, while the tissue sample is being taken. The farmer can then transfer the sampling data to the SNPshot mobile app on a smartphone via Bluetooth. The test tubes are removed from the cartridges and sent by courier to a DNA lab. Both the cartridges and their recyclable sleeves are quick and easy to load into the sampler. The seamless digitalisation of the entire process serves to minimise any previous challenges with regard to animal identification.

Sophisticated cartridge production

The sampling cartridges consist of nine components, one of which is filled with a saline solution. Manufacturing these cartridges was previously very labour-intensive, and was often a source of production bottlenecks. SNPShot therefore needed a system that would automate the process and produce finished cartridges at a rate of 20 units per minute. RML proposed an A101 injection-moulding assembly machine as a solution, which takes the cartridge bodies directly from an injection-moulding machine. The other eight components are loaded into separate tray conveyors, where they can be separated and made available for loading as separate units.

The assembly machine consists of three robots, three Beckhoff servo axes for precision positioning, eight cameras for part identification, a dispenser unit for saline solution, a QR barcode printer, and database integration for complete traceability of all components. Each cap in the cartridge is provided with a pre-printed miniature data matrix code. During the assembly process, this code is read and sent to a cloud database via a RestAPI interface. The code is then validated, and a secondary QR code is returned via the same interface. It is this secondary QR code that is ultimately printed on the outside of the cartridge body.

High-performance industrial PC and convenient visualisation

A C6030 ultra-compact Industrial PC from Beckhoff, with a quad-core Intel Core i7 processor with a frequency of 3,6 GHz, was selected as the controller. This high-performance processor offers all the computing power required for the demanding application. According to Jon Marden from RML, the system reliably handles sophisticated motion tasks, image processing control for a total of eight cameras, cloud-based data exchange, interface control for three robots, and the sophisticated HMI that combines all of these modules in a user-friendly operator interface.

Exceptional ease of use is afforded by the two touch-screen monitors connected to the Beckhoff Industrial PC: one with TwinCAT HMI for convenient visualisation and machine control, and another for a live feed from each camera in the image processing application. This gives the operator a clear insight into the entire process sequence.

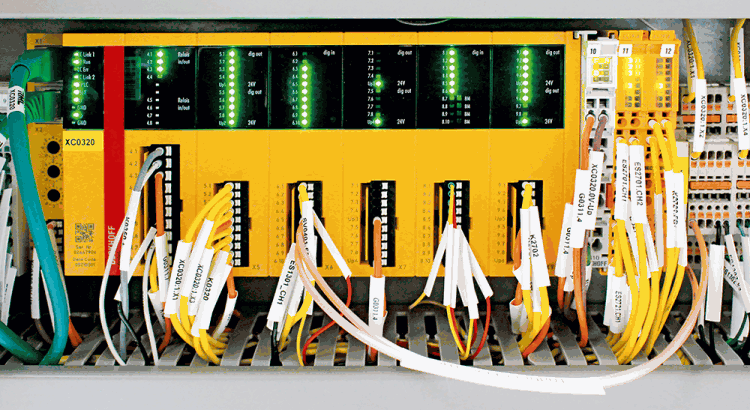

The precision axes are managed by a Beckhoff AX5103 servo drive, which communicates with the industrial PC via EtherCAT. In addition to the TwinCAT 3 HMI Server for visualisation, the system also uses TwinCAT 3 PLC and TwinCAT 3 NC PTP, TwinCAT 3 Database Server, TwinCAT 3 TCP/IP, and TwinCAT 3 IoT HTTPS/REST for efficient data communication. According to Jon Marden, the openness of the PC- and EtherCAT-based control technology from Beckhoff allowed RML to provide a high-precision positioning system without being limited to a single hardware supplier.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved