As industries increasingly integrate robotics and automation into their business operations, South Africa’s small and medium enterprises (SMEs) are beginning to recognise the benefits of robotics, and want their piece of the pie. For smaller businesses, robotic integration has always appeared more complex, mainly due to the initial cost and the complexity of adoption. Yaskawa South Africa acknowledges this and is addressing these concerns to create solutions that simplify the installation and operation process, making robotics both accessible and suitable for businesses of all sizes and in a myriad industries. This involves offering flexible financial models and investing in skills development to help smaller businesses optimise productivity and growth in a highly competitive market.

The South African SME landscape

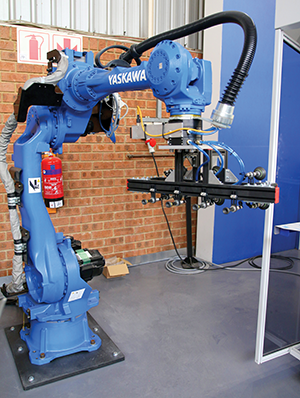

The adoption of robotics and automation in South Africa, particularly among SMEs, has been slower than in other parts of the world. This is a result of financial constraints, integration complexities, lack of technical expertise and accessible training, and the perception that automation is better suited for large-scale industries. Andrew Crackett, managing director of Yaskawa Southern Africa, believes that these challenges can be overcome with the right approach. “When working with SMEs, we take the time to understand their unique needs and objectives. This allows us to provide tailored robotic systems and end-of-arm tooling that are both adaptable and scalable, helping businesses grow sustainably,” Crackett explains. “Yaskawa’s robotics solutions can adapt to various applications and industries, and this versatility is critical for SMEs that often operate with limited budgets, and need systems that can grow as their business does.”

Tailoring robotics and automation for South African SMEs

For many SMEs, integrating robotics into their existing operations can be daunting. However, Yaskawa is able to simplify the process by offering interfaces that enable easy communication between robots and other equipment and, more importantly, with operators. In addition, flexible system configurations allow businesses to expand their robotic capabilities as their needs evolve. “Our solutions are designed to make it easier for SMEs to integrate robotics into their operations. We also offer extensive support and training, ensuring a smooth transition as businesses adopt new technologies,” says Crackett.

Overcoming financial constraints

Of all the perceived barriers to robotics adoption, the initial investment costs of robotics are often a significant concern for SMEs. “We’ve partnered with system integrators that offer leasing plans, helping SMEs afford robotics and automation by spreading out the costs over time,” Crackett explains. These financial solutions open the doors for smaller businesses that may not have had the capital for a large upfront investment for these advanced systems. This approach ultimately optimises the return on investment, making automation a feasible option for more businesses.

Cultivating a robotics ecosystem in South Africa

Aside from providing robotics solutions, Yaskawa is invested in creating a strong robotics and automation market in the country. “We’re helping to cultivate a strong robotics ecosystem in South Africa by working closely with local system integrators across specialised industries. In addition, we provide a comprehensive set of training programmes, from basic programming and maintenance, to more advanced troubleshooting and operator-specific skills,” Crackett says.

The focus on training is crucial, as one of the biggest challenges facing SMEs in the country is the lack of workers with any background in operating and maintaining these robotic systems. Yaskawa is helping to build a workforce that is not only capable of managing the technologies, but also contributing to the broader industrialisation goals of South Africa.

Driving economic growth and job creation

While there are concerns that the adoption and integration of automation will lead to job losses, Yaskawa has a different view. The company sees robotics as a key driver of economic growth and job creation in South Africa. By automating repetitive, labour-intensive tasks, businesses can increase productivity and reduce labour costs in this area, making them more competitive, while offering their current workforce opportunities to upskill, which, in turn, could see them furthering their own careers. Robotics optimises productivity, efficiency, and competitiveness. It also allows for the upskilling of employees, and reduces operator fatigue, improving the safety of business operations.

Moreover, Yaskawa’s business model is in line with South Africa’s National Development Plan 2030, which aims to improve industrialisation, optimise the country’s ever-present need for job creation and stimulate economic growth. By investing in local manufacturing and helping businesses adopt advanced technologies, Yaskawa is playing a key role in supporting the country’s industrialisation goals.

| Tel: | +27 11 608 3182 |

| Email: | |

| www: | www.yaskawa.za.com |

| Articles: | More information and articles about Yaskawa Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved