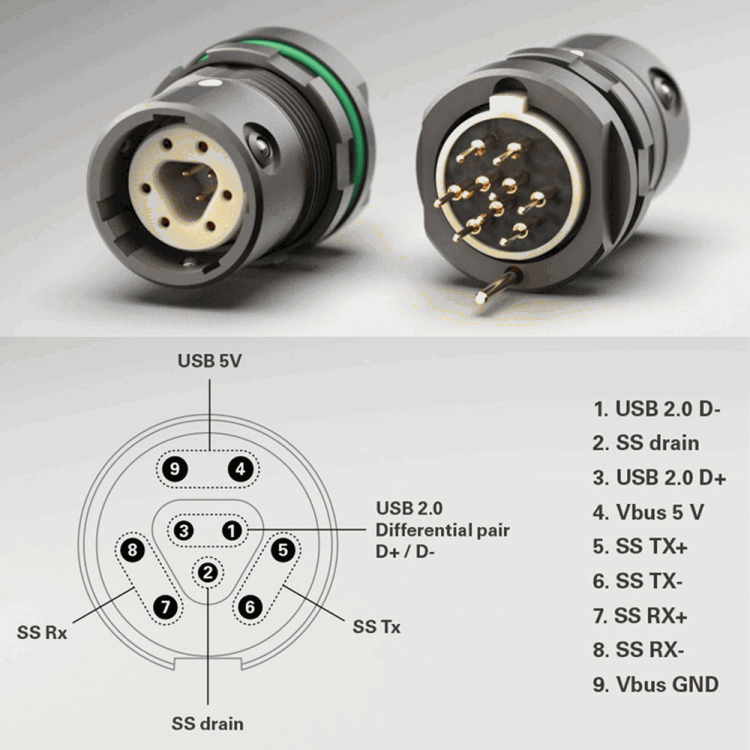

Data protocols are constantly evolving to enable interoperability and reliable transfer of increasing amounts of data at the highest speeds between increasingly more connected devices. To address this technological challenge, Fischer Connectors is expanding its platform capabilities to meet the most demanding connectivity requirements for high-speed data transfer using the USB 3.2 Gen 2 protocol up to 10 Gbit/s.

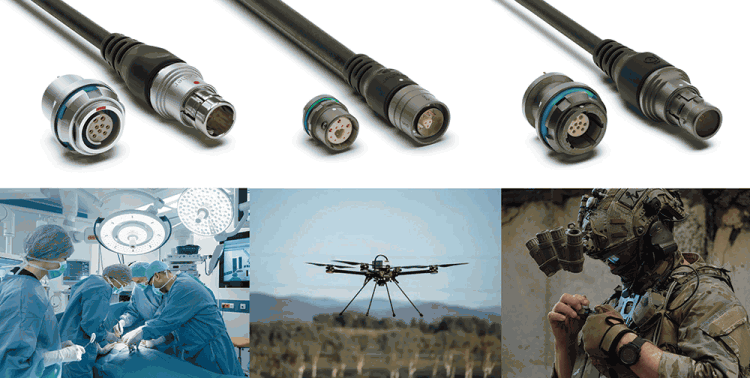

The Swiss-based company has developed new USB 3.2 connectors and cable assembly solutions in three of its flagship product lines to meet signal integrity and harsh environment requirements for medical, defence, industrial, and instrumentation applications such as:

• Surgical equipment in the operating room: USB3 cameras in orthopaedic surgery or endoscopic devices and instrumentation applications such as assembly production lines and outdoor inspections in radiation and/or contaminated areas rely on the highly customisable Fischer Core Brass Series in Ø 15,5 mm (size 1031 plug), with resistance to chemicals and sterilisation processes.

• Applications where size, weight and power are critical: Examples are miniature body-worn computers and peripherals, high-performance lidars and high-speed intercom boxes, using the ultra-miniature, high-density Fischer MiniMax Series in Ø 12,9 mm (size 08 plug) or 12 signal and power pins in Ø 14,9 mm (size 10 plug), including high power up to 8 A.

• Civil and military drones: These are equipped with USB3 cameras and a wide range of military specification (MIL-SPEC) applications, with the rugged, compact, lightweight Fischer UltiMate Series in Ø 18,5 mm (size 11 plug), 360° EMC shielding, and resistance to shock, vibration and corrosion up to 1000 hours of salt mist.

Fischer Connectors´ three series offer IP68 sealing (IP69 and hermeticity with a resin-sealed contact block for Core and UltiMate), extreme operating temperatures (MiniMax from -40 to 135°C, Core from -70 to 250°C, UltiMate from -55 to 135°C), high mating cycles (MiniMax up to 5000, Core and UltiMate up to 10 000), and three locking mechanisms: push-pull and quick release for the three series, plus screw for MiniMax. UltiMate also allows for blind mating with an extremely robust mechanical keying.

High-quality cable assembly to ensure signal integrity performance

Designing high-speed interconnect solutions requires expertise in cable assembly, high-performance connector, and signal integrity simulation, testing and design. During the design and characterisation process, engineers must address a highly complex combination of parameters such as impedance matching, line delay, insertion/return loss, crosstalk and EMC shielding.

High-quality cable assembly is critical to ensure reliable and efficient data transmission, signal integrity and overall system function. “To achieve successful high-speed data transfer from a device’s transmitter to its receiver, connectors and cables must be cross-optimised and undergo a series of compliance tests at the system level,” explains Ameny Chaabani, signal integrity engineer at Fischer Connectors. “USB 3.2 is a stringent protocol. Connector design, cable length, cable performance (loss), and the controlled and repeatable cable assembly and potting processes above 1 Gbit/s are some of the influencing parameters to consider. We must also study the full physical layer of a link as a whole − what we call system-level testing.”

© Technews Publishing (Pty) Ltd | All Rights Reserved