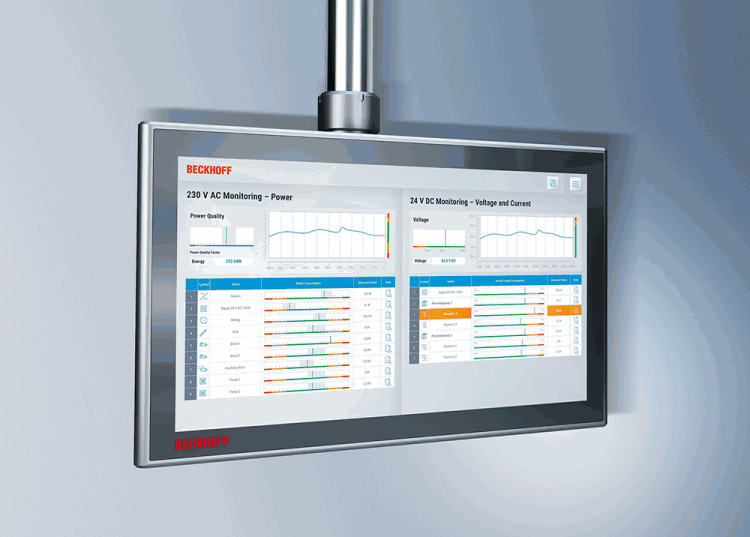

Transparent energy monitoring reduces both machine downtime and the necessity to oversize components. Added to these advantages are simplified preventive maintenance and increased production efficiency. The wide range of PC-based control technology from Beckhoff offers a solution that can be optimally adapted to individual applications with numerous SCT current transformers and EtherCAT power measurement terminals. These include the integrated monitoring of the AC and DC supply, the 24/48 V DC power supplies of the three new PS device series, and the EL922x electronic overcurrent protection terminals.

Universal system reduces work and costs

No machine or plant works without reliable power supplies and the corresponding fusing. If this is combined with high-performance recording of energy data, advantages already result during the design of the machine. Additional power measurement technology at the power supply inputs provides an overview of the total power, including any losses. The new high-quality power supplies from Beckhoff’s PS series employ a systems approach to PC-based control because only when all components are optimally matched to one another can a system work optimally. In particular, the EL922x overcurrent protection terminals integrated directly into the EtherCAT I/O system not only reliably secure the power in the individual supply paths, but also continuously measure it.

Machine manufacturers can avoid power peaks with this holistic approach. For example, they can reduce the connected load of the plant and also the installation costs for the end user, due to the smaller supply cable sizes. Furthermore, universal and system-integrated energy measuring technology satisfies the prerequisite for comparing the target and the actual state of the plant directly inside the machine controller. In this way, developing damage can be detected at an early stage, and process optimisation possibilities are easier to discover.

Until now, continuous data monitoring has mostly been associated with significant investment, often requiring costly integration of external sensors, sometimes with the help of specialised components. However the power measurement terminals, current transformers, overcurrent protection terminals and power supplies from Beckhoff make this possible with standard components, correspondingly low costs, and reduced logistics requirements.

Data transparency through complete measurement chain

As an automation specialist, Beckhoff can combine power supply components to form a transparent and complete system. This provides a comprehensive overview of the energy and power supply of the machine on both the AC and DC sides. The complete measurement chain begins with the SCT current transformer at the main supply to the machine. The power supplies from the PS device series provide a safe 24 V DC for all connected automation components, while the overcurrent protection terminals not only secure the individual lines behind them, but also continuously monitor the current consumption.

With the SCT series current transformers, Beckhoff has completed the power measuring chain from the recording of the physical measured values to the transmission of data to the cloud. The portfolio of current transformers covers all relevant applications for current intensities from 1 to 5000 A, and also ring-type and split-core transformer versions or three-phase transformer sets. There is a choice of two concepts which are highly scalable, and are thus suitable for a wide variety of applications. The SCT series is highly diversified, ranging from the low-cost three-phase transformer sets and standard industrial transformers for controls engineering through to solutions for test benches with particularly high accuracy requirements.

There is a wide variety of requirements in energy management in the machine environment and in the energy economy, ranging from pure grid monitoring and process control through to high-end power monitoring. Extended by four new EtherCAT I/Os, a comprehensive range of EtherCAT Terminals is highly scalable in terms of both price and performance. Together with the proven EL37x3 grid monitoring oversampling terminals (and the associated TF3650 TwinCAT Power Monitoring software library), the new EL34x3 EtherCAT Terminals for energy management make up a comprehensive range of products that optimally adapt to the respective application in a wide range of uses.

Distributed power measurement minimises costs

The new concept of distributed power measurement offers a particularly efficient and inexpensive way to obtain exact power measurement data, even in high complex systems. The central element is the EL3446 6-channel current input terminal for measuring currents up to 1 A AC/DC. It can be used to determine precise power values, even with physically separated voltage and current measurement. All relevant electrical data from the supply grid, including real measured values for power, can be determined with the EL3446 as a current measurement terminal. The voltage values required for the calculation of the power data are transmitted via an EL3443 three-phase power measurement terminal, which needs to be installed only once for each system. The active power and energy consumption for each of the connectable phases is then calculated in the EL3446. Information is thus available on the effective values of voltage and current, the active, apparent and reactive power or frequency, the phase shift angle, and the harmonics. This enables comprehensive grid analysis extending up to energy management.

This concept of distributed power measurement minimises hardware and installation costs. The wiring work for the voltage distribution is thus eliminated. In addition, the price per channel for power measurement is reduced by almost 50%, without having to reduce the sampling rate, as the number of measuring points increases.

Power supplies with optimised convection cooling

The new PS1000, PS2000, and PS3000 power supply series are the starting point for a powerful and safe power supply within the plant. They are suitable for virtually all areas of use, both in the 24 V and the 48 V DC range, and extending up to motion control applications with high requirements for back EMF. Excellent convection, minimised power loss, and high efficiency of up to 96,3% optimise the service life and reliability of the devices. The peak power capability of up to 150% makes it possible to provide up to 1,44 kW output power for short periods of time. In addition, the power supplies can switch off circuit breakers quickly and accurately through a precise tripping function, avoiding long machine downtimes.

The devices are specifically designed with good convection cooling properties in mind. In addition, components that are particularly temperature-sensitive and prone to rapidly ageing are placed at the bottom of the unit, as close as possible to the incoming cool air. Due to this temperature-optimised design, all components used are subject to less thermal stress, and thus attain a long service life. In addition, components that are subject to less stress retain their technical characteristics for longer, and the influence of external heat is minimised. All this has a positive effect on reliability.

Analogue monitoring terminal with fusing functionality

In the EL922x EtherCAT Terminal series, Beckhoff combines functions for comprehensive energy monitoring in a highly compact way, with electronic overcurrent protection for fusing 24 V DC plant components. These analogue monitoring terminals record the current and voltage values for continuous power monitoring. Among other things, these enable a detailed analysis of power consumption and voltage, and also the monitoring of voltage limit values. Furthermore, status information (on, off, triggered), trigger events (overload, short circuit) and preliminary warnings can be displayed.

The integration of electronic overcurrent protection directly into the EtherCAT I/O system reduces the costs and space required in control cabinets compared to other fusing products, without the need to use a conventional electronic solution as an inflexible standalone system. EL9227 EtherCAT Terminals also meet the most diverse requirements through numerous settings and process data options that enable transparent system monitoring. A total of 19 different one- and two-channel overcurrent protection terminals are available for current loads up to a maximum of 10 A.

The system-integrated overcurrent protection offers numerous practical advantages. It reduces wiring work as the supply to the neighbouring I/O terminals connects automatically when the terminal is plugged in. In addition, the control cabinet design benefits from space and cost savings by eliminating an unnecessary additional coupling device and further digital I/O or supply products. Furthermore, EtherCAT offers access to numerous process data such as load, load current, input/output voltage, under/overvoltage and reverse supply.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved