I never get tired of showing people how important it is to troubleshoot a control loop before trying to tune it, as so many people think tuning will overcome all problems. This month’s article covers two examples where all the tuning in the world would not have achieved good control.

Example 1: The sticky valve

In the first example, the operators in a petrochemical refinery were having trouble trying to control the flow of a light end-product, and had resorted to trying to run the loop in manual. However, from time to time there were quite a few load disturbances which affected the flow badly, and they had to frequently revisit the loop to make adjustments.

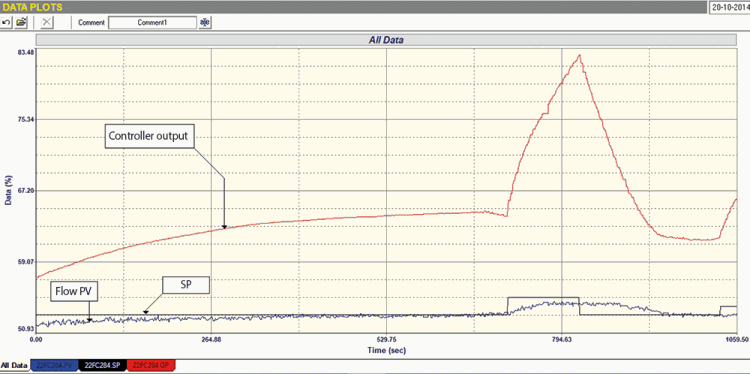

Figure 1 is a closed-loop test ‘as found’ (ie, with the original tuning in it). At the start of the test, one can see that the process value (PV) is slowly drifting up to the setpoint (SP) and, after about 10 minutes, finally reaches it. The SP was then stepped up by a small 2% after which the PV moved up but then seemed to settle before reaching the SP.

The controller output (PD) had moved up by about 20%, and was still rising quite steeply when the SP was stepped down by 2% again. At this stage the PD came down very quickly, but it took the PV quite a while before it, too, started moving down. This is a sign of the valve not moving and indicates that there is hysteresis or stickiness in the valve. The PV finally got back down to the SP with the PD well below the value it had been at the start of the step-up in SP. This would confirm that there is probably bad hysteresis in the valve.

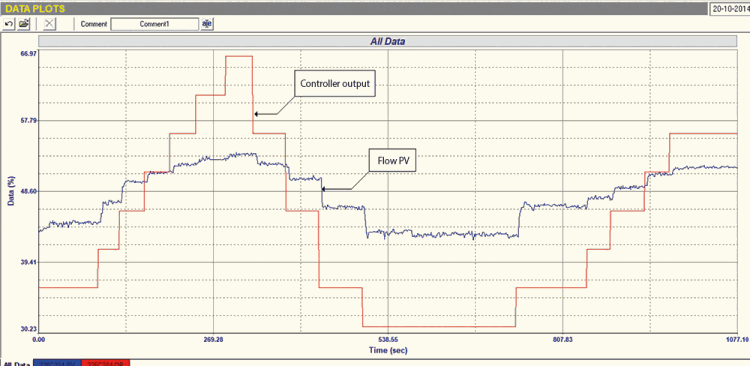

The open-loop test is shown in Figure 2, in which the following can be seen:

a) When the PD is below about 40%, the PV responds well to steps in the PD. When the PD is above that, the steps in PV are very much smaller, and became smaller the higher the PD was stepped. Although there is a chance that there is something strange with the installed characteristics of the valve, it is far more likely that the flow is reaching a point of saturation, probably due to insufficient pressure in the pipe.

b) The process gain of the loop is about 0,5 – based on the lowest step changes. This is usually a sign that the flow transmitter has too wide a span, but this might not be the case if the flow could have reacted better if there were more pressure in the pipe.

c) There is no real indication in this test of valve hysteresis or stickiness, but it must be taken into account that these things do not always show when a valve is reacting to step changes in PD.

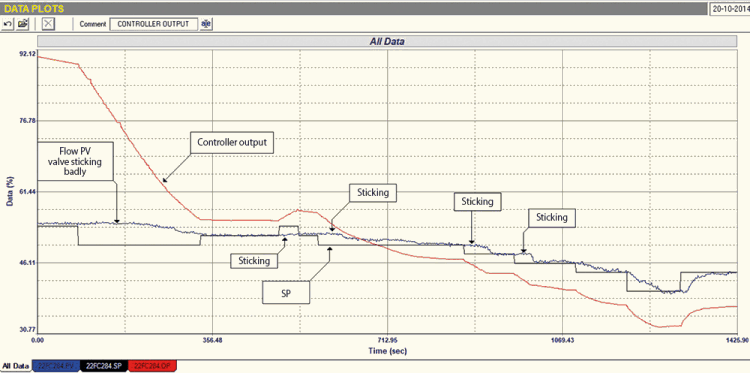

A final closed-loop test was carried out with improved tuning, and this is shown in Figure 3. It can be seen that the valve was in fact extremely sticky, and taking a long time to react to many of the SP changes. Unfortunately, the plant needed to keep the SP at around 50%, where it was in the saturation region, and this is a case where the plant needed to try and increase the pressure to get the flow to react properly, and also the valve needed servicing. Only then would it be able to attain good control.

Example 2: Waste gas flow

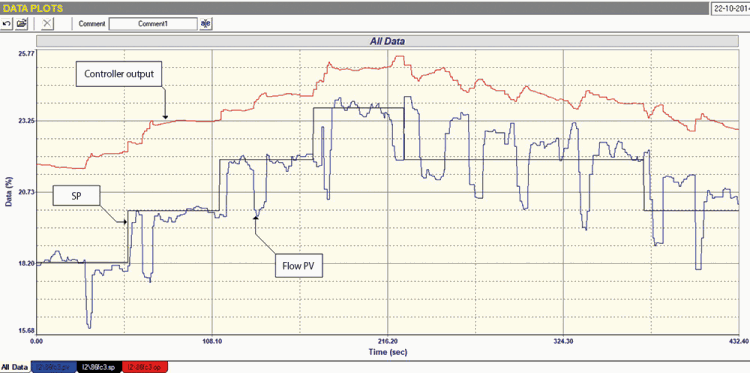

The second example is even more dramatic. The loop’s purpose was to control the flow of waste gas to the flare in the same plant as above, which is quite an important control in such plants. The problem was that the flow followed the setpoint, but cycled quite wildly about it.

Figure 4 shows the closed-loop ‘as found’ test with changes in SP being made, and it can be seen how badly and frequently the rapid fluctuations occurred.

Many people in the C&I; department had tried tuning the controller to stop the fluctuations, but all to no avail.

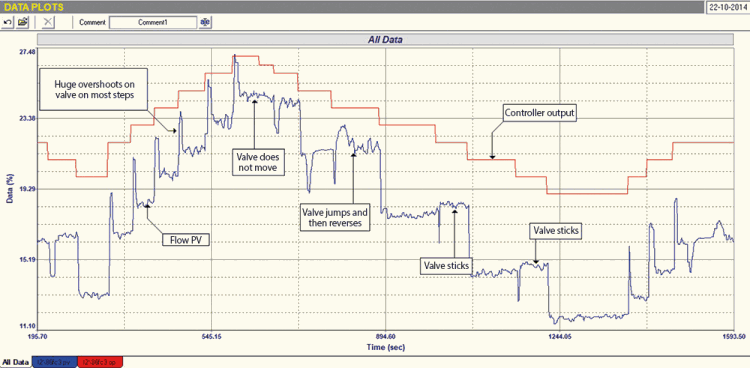

Figure 5 is the open-loop test, which immediately showed what was happening. The valve was jumping around badly and, upon changes in the PD signal, produced huge over- or under-shoots. Sometimes it didn’t respond properly at all, sometimes it cycled, sometimes it moved the wrong way, sometimes it stuck, sometimes it moved too much – all making it very non-repeatable.

This is one of the most interesting and dramatic examples I have seen of a valve not following the PD signal properly. Luckily, the fluctuations were all in a relatively narrow band, so an average flow control was possible. Another interesting thing is that nobody in the C&I; department was aware of the problem, and all had tried tuning.

It was later found that the actual problems with the valve were that, first, there was some very bad play in loose linkages and that, second, the positioner had not been properly tuned.

About Michael Brown

Michael Brown is a specialist in control loop optimisation, with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He now presents courses and performs optimisation over the internet.

His work has taken him to plants all over South Africa and also to other countries. He can be contacted at: Michael Brown Control Engineering CC,

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved