Moxa’s MXview One network management software is designed for monitoring and diagnosing networking devices in industrial networks. MXview One provides an integrated management platform that can discover networking devices and SNMP/IP devices installed on subnets. All selected network components can be managed via a web browser from a local site or through remote access – anytime and anywhere.

In addition, MXview One supports the optional MXview Wireless and MXview Power add-on modules. MXview Wireless provides additional advanced functions for wireless applications to monitor and troubleshoot networks and help minimise downtime. MXview Power provides additional advanced functions for power applications based on IEC 61850, to monitor and troubleshoot substation networks in real time.

Intelligent process control is a typical static wireless application in smart manufacturing where customers use Wi-Fi to establish the communication between the clients installed at production lines and the control centre. However, an unstable wireless connection might lead to incorrect decision making due to incomplete on-site information or dropped connections, affecting optimal production processes.

It is often difficult to know the exact status of the Wi-Fi connection and fix issues immediately the moment they occur. The MXview Wireless add-on module simplifies network management by allowing users to get detailed device information and performance indicator charts for individual AP and client devices from the device dashboard.

A major benefit of this module is that users can view the wireless and wired network status from a single main control dashboard. Furthermore, users can monitor connectivity patterns and customise alert settings to immediately notify of any problems. In turn, this allows engineers to perform on-site troubleshooting quickly and efficiently, ensuring maximum network availability.

In automated material handling (AMH) systems, the Wi-Fi connections must be able to dynamically adapt to the constantly moving vehicles. An unstable wireless signal could easily disrupt the operation of these systems. However, wireless connections are invisible and affected by many different factors.

The MXview Wireless add-on features a dynamic topology view to let users see the status of wireless links and connection changes at a glance. Moreover, since automated vehicles constantly roam between different APs around the facility, users can overlay the network topology on top of a floor map of the facility, to easily locate the vehicle by just checking the client’s wireless connection. This helps save a great deal of time when trying to identify a malfunctioning client device.

The roaming playback function lets users review a client’s roaming history of the past 30 days to analyse an incident. Users can leverage this function to find and address the root cause more efficiently, instead of having to consolidate and examine individual device logs. Exclusively developed by Moxa, these two functions are specially designed to fulfil the growing requirements of automated factories, smart logistics and other intelligent applications.

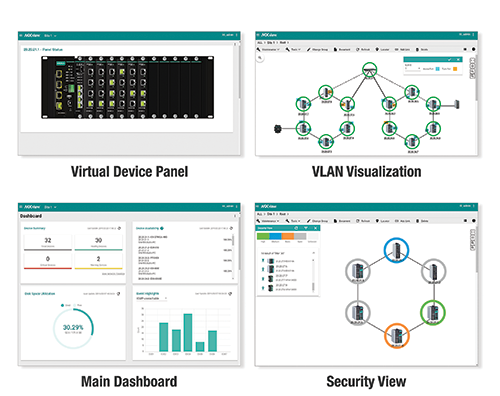

Visualisation capabilities allow for the discovery of up to 2000 Moxa devices and SNMP/ICMP devices within scan range, and provide visualisation of redundant link status and device roles of network redundancy protocols. Other visualisation features include network traffic loading with a colour-coded link, and power consumption of managed PoE devices.

Network diagnostics and event notifications detect problems in real time with SNMP trap/inform, or periodic polling, and trend graphs can be generated to track bandwidth utilisation and error packet rate statistics, accurate to four decimal places. The platform supports a Syslog server for centralised message management, multiple options for events with self-defined thresholds and durations, real-time device availability monitoring, and RESTful API and web widget for integrating MXview One into an existing system.

An inventory report can be generated for each device on the network, and comprehensive reports of device properties can be compiled. MXview One also enables device firmware management from a single platform, and the ability to back up the configuration of multiple devices and the entire MXview One database with one click, including topology, job scheduling, events and device properties. This is further enhanced with scheduling for periodic configuration backup, the ability to save a history of configuration changes, and a comparison tool for checking differences between two configurations.

Demand-based licences are available to increase the premissible node limit for monitoring, and add-on licences for MXview Power and MXview Wireless are optional.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved