Efficient spillage solution

August 2022

Analytical Instrumentation & Environmental Monitoring

OST-Africa’s range of materials handling, screen and transmission products includes an efficient spillage solution designed to prevent production losses during materials handling in diverse sectors.

“This cost-efficient spillage system, which encompasses various products that operate together to form one highly efficient system, has important benefits over conventional systems which are labour intensive, costly to operate and require additional equipment,” says Nolene Streicher, managing director, OST-Africa (part of the Engineering Solutions Group (ESG) of Invicta Holdings Limited). “Advantages of the OST system include simple installation, modular components for extended service life of the system, reduced maintenance and a low-cost solution to spillage problems.”

The OST spillage system consists of a dynamic impact bed, the High Impact Torsion (HIT) system, the skirt clamp and skirt wing, impact zone panels, chute vibrators, duff feeders, primary and secondary belt scrapers, and the bias plough.

The dynamic impact bed is a shock absorbing trough which is mounted underneath a conveyor belt. It is installed at transfer points where fine or coarse heavy material is being transferred, and where there is a build-up of materials in the transfer chute. The HIT system combines a heavy-duty idler frame with a high-impact torsion arm system to absorb the impact of material which falls onto the belt.

The skirt clamp, which is the conveyor system’s spillage controller, ensures that positive pressure is always applied to the side wall. The skirt wing is designed to support a conveyor belt between the idler and frames when sagging occurs, in order to prevent overflow spillage.

OST impact zone panels are used at high-impact points in transfer chutes which are continually put under high stress and therefore have the highest maintenance requirements. This impact zone panel absorbs impacts, and high-wear resistant liners ensure efficient operation and extended service life.

Chute vibrators prevent material blockage in a chute. Duff feeders, which accommodate the removal of dry or wet material from underneath belt scrapers down to collection points, also allow access for easy maintenance of conveyor rollers and belt scrapers.

The primary belt scraper blade tip is kept in positive contact with the belt surface while the secondary belt scraper is segmented from all scraper components, for extended service life. The bias plough prevents duff that remains on the belt from damaging the return pulley.

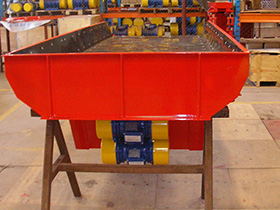

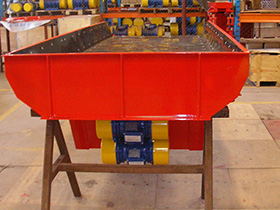

OST’s materials handling product portfolio also includes the Grizzley Feeder System (GFS) which is custom-made to suit each application. This mobile feeder system, which constantly controls the feed of product onto conveyor belts at a rate of up to 80 tons per hour, can be quickly and easily dismantled and relocated when necessary. This system, which ensures optimum production, reduced wear and low maintenance, is also designed for no spillage.

Electrical panels for these feeders are fitted with manual and automatic switches, frequency inverters, overload switches, flexible vibration cables and a step- down transformer. OST bulk handling systems are supported by OST-Africa’s specialised design and installation team, which ensures these custom-built systems meet exact requirements in any application.

Further reading:

Precision in every drop, powered by ICP technology

Wearcheck

Analytical Instrumentation & Environmental Monitoring

Elemental profiling using Inductively Coupled Plasma – Optical Emission spectroscopy provides useful information on the chemical composition of lubricants.

Read more...

A trusted oxygen analyser back in action

Elemental Analytics

Analytical Instrumentation & Environmental Monitoring

After a period of discontinuation, Servomex’s Oxy 1810 oxygen analyser has officially returned.

Read more...

Multi-channel pH and conductivity controller for the water sector

Senseca

Analytical Instrumentation & Environmental Monitoring

The measurement of pH and conductivity plays an integral role in water systems. Senseca South Africa has introduced a multi-channel controller that allows the connection of up to five digital sensors and a frequency-emitting flow sensor.

Read more...

DEKRA Industrial sets new standards for asset integrity in local petrochemical sector

Analytical Instrumentation & Environmental Monitoring

DEKRA Industrial South Africa has strengthened its position as a leader in hydrogen-induced cracking inspections through a strategic combination of advanced non-destructive testing techniques, investment in state-of-the-art inspection equipment and global technical collaboration.

Read more...

ABB leads in emissions monitoring with industry-first data acquisition system proficiency test

ABB South Africa

Analytical Instrumentation & Environmental Monitoring

ABB is the first company to offer a complete package of continuous gas analysis and DAHS systems fully compliant with international standards.

Read more...

Ensuring clean and safe water

Endress+Hauser South Africa

Editor's Choice Analytical Instrumentation & Environmental Monitoring

Endress+Hauser’s comprehensive range of disinfection sensors is designed to monitor and control disinfectant levels in water treatment processes.

Read more...

High-precision measurement of insulating gases

WIKA Instruments

Analytical Instrumentation & Environmental Monitoring

WIKA has launched the next generation of its GA11 gas analyser. It enables switchgear operators, manufacturers and maintenance companies to record the quality of SF6 gas and alternative insulating gases.

Read more...

Say goodbye to missed contamination with real-time colour monitoring

Analytical Instrumentation & Environmental Monitoring

Applied Analytics offers seamless and rapid colour monitoring in processes with an industry-proven analyser that quickly and accurately monitors colour in your sample stream for impurities and inconsistencies.

Read more...

Metrology laboratory is the heart of data-driven production consistency

Analytical Instrumentation & Environmental Monitoring

Pressing and welding have been at the core of Tier 1 automotive supplier, Malben Engineering for 50 years; but it is the company’s investment in its state-of-the-art metrology laboratory which has set it apart.

Read more...

Unlocking precision: The future of inline concentration measurement

Analytical Instrumentation & Environmental Monitoring

[Sponsored] In today’s resource-conscious industrial world, manufacturers are under growing pressure to optimise productivity, ensure consistent product quality and minimise waste. One of the most effective levers for achieving these goals lies in mastering concentration measurement, and Anton Paar is redefining how it is done.

Read more...