Manufacturing organisations are facing a once-in-a-generation global crisis, as the winds of change have become a storm of disruption. There is a huge shortage of talent and skills in manufacturing, raw material and energy costs are skyrocketing, and supply chain disruptions continue, including port congestion and shortages of semiconductors, truck drivers and containers. In addition, due to escalating geopolitical threats, many manufacturers have been impacted by production disruptions and have lost assets and key sales markets.

Sustainability is becoming more important than ever. Manufacturers must operate in an increasingly sustainable way by defining clear purpose-driven goals that align with their core values, and by engaging all their stakeholders in shared and sustained value creation. In creating such value, manufacturers serve not only their shareholders, but also employees, customers, suppliers, local communities and society at large. Companies need to rethink their business decisions around sustainability to meet stakeholders’ expectations on top of their immediate business needs.

Manufacturers’ key business priorities

With the ever-evolving market dynamics, manufacturers’ key business priorities also continue to evolve. In particular, manufacturing organisations increasingly realise that business process reinvention and business model transformation must be enabled by solid plant capabilities and a ‘back to basics’ attitude supported by modern technology that sees operations as a critical contributor to a company’s overall value proposition.

To manage continuous disruption, manufacturers are increasingly looking to:

• Smart operations/factory and continuous feedback loop innovation to drive operational excellence.

• Sustainability embedded in their operations and supply chains (via resource efficiency, waste reduction and decarbonisation) on their journey to net-zero emissions and minimal resource impacts.

• Data-driven product and service innovation to enable extreme efficiency differentiation in a competitive market.

• Improved resilience to respond to variable market demand.

• Mass customisation to meet individual customer requirements.

Sustainability must permeate traditional business siloes

To realise these objectives, technologies enabling decision-making capabilities and real-time operational visibility will be put centre stage, along with those that support granular energy or material consumption analysis for both cost optimisation purposes and to meet sustainability goals.

It is worth noting that the technologies that enable companies to be sustainable can also improve their cost efficiency. Energy efficiency systems, for instance, that provide the required granularity of data to address both carbon and energy consumption footprint in an automated way, can also enable companies to become more sustainable and more efficient.

Sustainability matters in the factory too, not just in corporate reporting

According to IDC’s 2021 ‘Worldwide Future of Operations Survey’, 72% of industrial organisations consider their environmental metrics to be performing better today than two years ago. As a result, running operations in an environmentally sustainable fashion is increasingly becoming a corporate KPI. This is driven by government policy and regulation; public pressure from shareholders, customers and other stakeholders; global corporate policies; and access to better financing opportunities. With increased scrutiny, there is pressure to move beyond simply reporting sustainability metrics to using them as an operational control parameter.

IDC expects that by 2026, 60% of G2000 companies will use sustainability KPIs and data as primary operational control parameters, compared with less than 20% in 2021, according to IDC’s Worldwide Future of Operations 2022 predictions. The challenge – and the opportunity – is to use sustainability metrics to control operations with little or no negative impact on core production, quality and cost targets. Success will require significant investments in expanding the use of operational data, and the extraction of insights from it using analytics.

Environmental excellence makes business sense

The key point is that environmental excellence should not just be driven by regulation. It also makes business sense, even in the absence of rules requiring it. Driven by increased demand for environmental accountability in manufacturing ecosystems, by 2025, 40% of G2000 manufacturers will use traceability technologies to mitigate risk and boost transparency, according to IDC’s Worldwide Manufacturing 2022 projections.

The journey toward environmental excellence brings together a set of technologies and capabilities that enable companies to become net-zero through improved end-to-end horizontal and vertical transparency, availability of real-time data, and AI/ML turning complexity into understandable outputs.

Opportunity to reset factory operations with digital-first, innovative initiatives

Manufacturers that invest in digital initiatives to boost their sustainability efforts realise other benefits in the form of a resilient and distributed operational decision-making framework. This framework drives faster change execution, delivers productivity gains compared with non-digital lean initiatives, and improves revenue and profit performance.

IDC predicts that by 2023, 40% of G2000 companies will develop all-new processes such as ‘remote operations first’, compared with the limited number of remote operations processes in 2020. IDC’s 2021 Worldwide Future of Operations Survey identified that 75% of industrial organisations will be monitoring many of their assets remotely, while maintaining a level of staffing on the ground for support. This will be enabled by existing and available technologies such as:

• Digital twins: the more new physical assets and processes that are modelled as digital twins, the more optimised the operational performance.

• Vision analytics in operations: moving beyond quality inspection and security use-cases to those focused on performance, experience and safety.

• Centralised security management tools to bridge the IT/OT gap: as a foundational component to bridge the IT/OT gap to facilitate contextualised OT security.

These elements must be brought together with a consistent factory automation approach. Assets, devices and even workers produce an enormous number of data points, and we are seeing a convergence of IT hardware with it becoming an increasingly important production asset (for example, 3D printers, vision systems, scanners, wearables and RFID) and ‘traditional’ OT assets and equipment becoming a critical element of the IT infrastructure, as these devices come with out-of-the box connectivity features or are retrofitted in brownfield deployments.

Operational equipment instrumentation has increased over the past few years and plants are also getting more connected. In other words, the success of future operating models is dependent on data management and, in particular, on managing closer to the data source, i.e., the operations equipment. So, manufacturers should not only focus on ‘back to basics’ when it comes to increasing the production floor focus, but also when it comes to data collection and management.

Create a data-driven ecosystem

As discussed, manufacturing organisations are being held to account by several stakeholder groups – investors, employees, customers, etc. – and need to report on their sustainability performance objectively and comparatively. Manufacturers need to address a range of sustainability topics in the context of assessing their impact on people and the environment, and how they affect their operations.

Once a manufacturer has defined its sustainability strategy and is ready to operationalise it, one of the biggest challenges is the data conundrum. Manufacturers need to access a large and varied set of data that is spread across the organisation. As data resides in multiple repositories, just gathering and classifying the required data is a significant challenge.

Once data is gathered and classified, the next step is verifying its accuracy and quality, through either internal or external audits, before reporting the data. Some manufacturing organisations are still using spreadsheets and manual processes, and are unable to efficiently process the huge amount of available data. IDC believes technology can play a significant role here to alleviate many of the challenges.

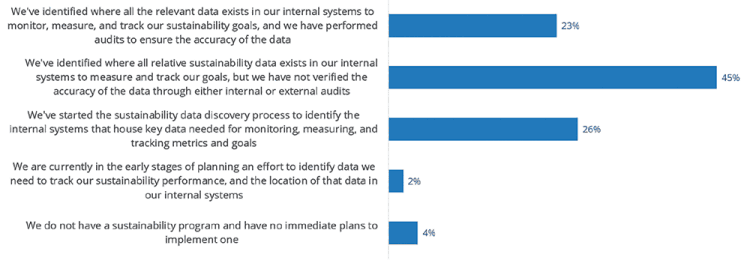

When asked about the current state of the organisation’s sustainability programme in terms of access to and use of required data in IDC’s Future of Enterprise Resilience Survey Europe, in early 2022, only 23% of the manufacturing, utilities, and oil and gas companies had identified all the relevant sustainability data that exists within their internal systems and had performed audits to ensure the accuracy of the data

To be truly sustainable, manufacturers need to collaborate outside their own boundaries. Data sharing across ecosystems is crucial. According to IDC’s Worldwide Manufacturing 2022 Predictions, by 2024, 40% of manufacturers will share data in their ecosystems (partners, customers, suppliers), thereby improving the overall equipment effectiveness (OEE) of their factory operations by an average of 10%. By sharing and exchanging data in a cloud-based industry ecosystem, for instance, manufacturers can generate more insights than by analysing only data from their own domain. The more manufacturers act based on such insights, the more they improve the performance of their factory operations and progress on their sustainability journey.

Finding the right technology strategy

Manufacturers are committed to working toward their sustainability goals and are increasingly moving away from fragmented approaches to more integrated metrics and materiality-driven sustainability business strategies. There are two main areas to be considered here – bringing together the organisation and then undertaking the sustainability journey.

There are multiple internal stakeholders who either drive or influence the sustainability agenda, beyond the specific remit of the chief sustainability officer (CSO). Being sustainable in an holistic way requires close collaboration among different personas, including technology specialists such as the chief digital officer (CDO) for driving transformation and innovation, the chief information officer (CIO) for digital infrastructure, the chief financial officer (CFO) for budgets, and the chief procurement officer (CPO), chief supply chain officer (CSCO) and chief operating officer (COO), among others.

After aligning the different personas, manufacturers must undergo a journey as they execute their sustainability strategies:

• In the early stages, they need to understand what their sustainability goals should be and how these goals relate to their overall business strategy.

• They then need to look for the right solutions, while thinking about the right infrastructure such as scalability, connectivity, openness and security.

• Next, they must check their digital transformation strategy roadmap to find out to what extent the current/planned solutions can help them on their sustainability journey.

• Then manufacturers need to look for a technology partner. They may also choose to engage with tech partners at earlier stages of their journey.

Technology vendor Rockwell Automation’s strategy is to support its customers who are under huge pressure to reach sustainability goals and provide data transparency to their stakeholders across industries. It says that reaching its sustainability goals is one of the many benefits of digital transformation.

Rockwell’s initial focus areas stem from its expertise in factory automation to drive environmental change – specifically energy, water, and waste – both from an industry perspective and from a horizontal application focus across all industries it serves.

• Energy management. As its customers deal with one clear challenge – the lack of visibility of energy data and how to use it as an opportunity for operational excellence – Rockwell is making significant investments in software solutions, such as FactoryTalk Energy Manager, to help customers leverage that data. This is helping customers to take environmentally data-driven decisions that are both profitable and sustainable.

• Smart water. From a water perspective, Rockwell Automation is working with its traditional industrial users and at the municipality level. Smart water solutions leverage innovative software and analytics to improve operations visibility, system reliability and worker productivity, while supporting security needs and meeting regulatory obligations.

• Waste management. For years, Rockwell Automation has had global remanufacturing/repair facilities that enable the circular economy and reduce the environmental footprint. One of its immediate focus areas is around creating an environmental footprint scorecard to help its customers quantify their environmental footprint in both buying and operational decisions.

Challenges

The key challenge for companies such as Rockwell and its customers in pursuing digitally enabled sustainability goals is to transition the granularity of acquired data on the shop floor into a corporate-level and multi-enterprise decision-making and reporting environment. IDC has seen how many companies are unprepared for the complex data ecosystem, and estimates that by 2023, only 25% of G2000 companies will have moved beyond the enforcement of IT policies in operations, resulting in a limited ability to extract more value and insights from their operational data.

As a result, manufacturers are increasingly aware that they need support around factory innovation data management from companies that know this topic best. IDC forecasts that by 2024, 70% of G2000 customers that have IT/OT initiatives will embark on new programmes or double their spending with service partners as they race to infuse digital resilience into their operations.

Conclusion

Technology provides an opportunity to leverage environmental and social data-driven decisions – innovating with sustainability as an objective across the physical and digital threads.

‘Digital’ and ‘sustainable’ have become business imperatives. The difficulty for many industrial organisations, however, remains their ability to monitor and trace their sustainability achievements in a comprehensive, credible way – be it carbon emissions, energy mix, waste management or supply chain compliance. They must look at the entire business lifecycle to identify strategic ways to address sustainability in their operations and through their offered products and services, enabled by technology.

Such an accelerated shift also requires a change of pace. This is where technology suppliers and providers can play an integral role. They are driving business by becoming sustainable organisations in their operational activities, incorporating innovation into their product and service offerings to become greener, and most importantly facilitating their customers’ transition to becoming more sustainable enterprises – because profit and purpose should work hand in hand.

Technology providers such as Rockwell Automation offer advanced manufacturing solutions and technologies that enable manufacturers to define how to transform responsibly and enable sustainable, inclusive and resilient value creation through ESG metrics.

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved