With particularly high frequencies, UHF RFID systems allow reading ranges of several metres. Tags, whose communication via the air interface is defined in accordance with ISO/IEC 18000-63 (EPC global Class 1 Gen 2), play a decisive role in this. If the chosen tags are, however, not suitable for the application, if they are not sufficiently durable to withstand the process or if they do not deliver the necessary performance (in terms of reading range), the reading rate of the RFID system will be too low or the entire system may fail. It is therefore necessary to understand the technical demands and physical conditions of the relevant process in as much detail as possible. These diverse conditions of different industries and applications generate a wide variety of tag-specific requirements, affecting aspects such as the design or the memory size. UHF RFID systems are being used for more applications all the time so the process of choosing the appropriate tag is becoming more and more complex.

1. Frequency ranges

In which region will the tag be used? There are basically three variants:

• ETSI (European Telecommunication Standard Institute): the tag is optimised for a frequency range of 865-868 MHz – this range is used in Europe, Russia and India, for example.

• FCC (Federal Communications Commission): the tag is optimised for a frequency range of 902-928 MHz – primarily used in America and Asia.

• Global: the tag functions over the wide frequency range of 860-960 MHz and can be used in all international regions.

When choosing a tag, it is essential to know where the tag will be used. Most South African industries fall under either the European or Global Regional Standard.

2. Material of the objects being identified

When choosing a tag, it is important to consider the surface on which the tag will be mounted. In certain circumstances, the read/write range can be greatly reduced by the electrical conductivity of the mounting surface. For example, the ends of the antenna will short-circuit if a conventional paper label is mounted on a metallic surface. As a result, the tag cannot be supplied with energy and is no longer readable. Other materials and substances that suppress the electric field include liquids, wood, textiles and plastics.

For some applications, special requirements are set out in the data sheet of the tag:

On-metal: these tags are suitable for mounting on metal. Insulating materials inside the tag prevent a short-circuit of the ends of the antenna. It is important to note that on-metal tags often function within a smaller frequency range. Different versions are therefore available for the ETSI and FCC frequency ranges.

High temperature: in certain processes, tags may be subjected to significant temperature fluctuations. Before choosing a tag, it is therefore important to know what operating and storage temperatures to expect and whether high temperatures occur occasionally or regularly. It should be tested how fast the tags heat up or cool down in the application. In this context, it is necessary to consider the expected number of cycles and thus the impact on the life expectancy of a tag.

How large the tag must be and where it can be mounted depends on the physical size of the object being tagged and the required reading range. In general, the size of the antenna structure on a tag has a significant impact on the reading range.

3. Tag design

Tags come in several body styles, based on application environments, ambient conditions and the ability to fulfil different requirements:

• Label: The antenna and chip are placed on a thin base layer and then covered with a thin film or printable paper. This type of tag is protected against mechanical stresses only to a very limited extent. If the tag is deformed because of impacts or bending, there is a risk that the connection between the antenna and the chip will break and the tag will no longer function.

• Hard tag: these comply with high protection classes up to IP69K and are made from materials that will not show cracks, breaks or other damage, even after a long service life.

• Sensor tag: combining sensors and RFID tags (labels and hard tags) is an interesting technical solution. In this case, familiar components of the tag, generally the antenna and IC, are enhanced by electronics for carrying out various measurements. Temperature and humidity measurements are often performed by sensor tags.

4. Memory buffer

What data and how much needs to be stored on the tag depends on:

• Scenario 1: the customer saves all process-relevant data on the tag. A high storage capacity is required. If the tag is lost or becomes faulty, all data will be lost.

• Scenario 2: the customer assigns only a unique ID and stores all process-relevant data in their own system. A low capacity is sufficient with 96 bits usually being enough.

Data can be stored in two memory buffers on the UHF tag:

1. EPC (electronic product code) memory: this memory buffer must be present in accordance with the EPC Global Class 1 Gen2 specification and is usually at least 12 bytes in size. It is suitable for assigning a unique ID and can be read in bulk. Multi-tag applications are possible.

2. User memory buffer: this is optional and can be up to several kilobytes in size, making it suitable for storing large amounts of data. However, since it cannot be read in bulk, multi-tag applications are not possible. It is possible to read the memory buffer of a specific tag within a group by specifying the EPC.

5. Optimum mounting method

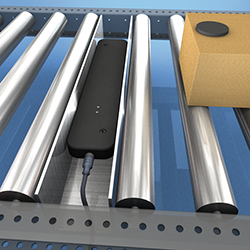

There are several ways to mount a tag to an object, for instance, glue, screws, cable ties, potting, or welding. The optimum mounting method depends on the type of tag, the ambient conditions and the surface of the tag.

6. RFID systems from a single source

The BL ident complete RFID system from Turck Banner offers solutions in the HF or UHF range with interfaces for use in a plant or switch cabinet. Since 2006, this RFID system has been used successfully in industrial environments and is being developed continuously. Over the years, Turck Banner specialists have acquired in-depth practical expertise that users can benefit from in their own RFID projects. For highly-complicated applications, integration partner, Turck Vilant Systems, operates a proven middleware system to help smooth integration of UHF systems into specific processes. The company has demonstrated its expertise in integrating solutions in MES and ERP systems through several complex projects. Full transparency along entire supply chains can be achieved through reliable detection of goods at RFID checkpoints using simple, cost-effective labels https://tinyurl.com/7dmr2326.

Advantages

More efficient processes in production and logistics:

• Avoid time-consuming manual work steps and simplify inventory management.

• End-to-end identification and tracking of goods flow.

• Bulk reading – detect several tags at the same time.

Improved quality control

• Eliminate errors, for example, during tool change or material feed.

• Full transparency along the supply chain thanks to the clear allocation of goods.

• Tamper protection via individual coding.

Future-proof investment with high flexibility

• Expandable RFID system consisting of tags, read/write heads, interfaces, connectivity and fieldbus technology.

• Rewritable tags for sustainable use.

• Combination of HF and UHF detection for complex or new requirements.

| Tel: | +27 11 453 2468 |

| Email: | [email protected] |

| www: | www.turckbanner.co.za |

| Articles: | More information and articles about Turck Banner Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved