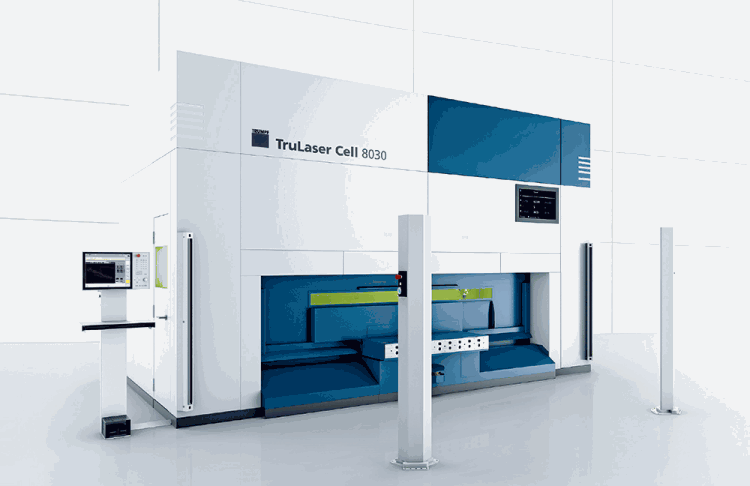

As a pioneer in 3D laser processing technology, Trumpf offers complete machines and systems with optimally co-ordinated components, in addition to beam sources and beam components. The advanced TruLaser Cell series machines utilise industrial PC technology and EtherCAT I/O components from Beckhoff. The current, second-generation TruLaser Cell 8030 combines maximum production reliability and productivity for 3D laser cutting.

The TruLaser Cell 8030 is designed for the automotive sector and can be flexibly configured. A large version for cutting complete side parts is available, along with a smaller variant for manufacturing individual parts and segments of the bodyshell. The high-speed rotary changer provides a 20% shorter turning time of only 1,8 seconds, minimising non-productive times and increasing the overall performance. In comparison to the predecessor model, the machine cuts a hot-formed vehicle cross member, for example, with 10% higher machine dynamics, 10% lower non-productive times and 30% faster slug control.

Flexible machines and control systems are essential

The TruLaser Cell 8030 can process large series parts cost-effectively and with high flexibility. The NC programming offers maximum flexibility in terms of the component geometry, which can also be subsequently modified to address new requirements using the variable laser tool. Thomas Brauchle, service quality assurance manager at Trumpf explains: “With Beckhoff we have a partner who supplies us with state-of-the-art automation technology that has the flexibility to address the special requirements of a laser processing system.”

Another key factor behind the decision to choose Beckhoff technology was the underlying EtherCAT communication system. Brauchle confirms: “We utilise EtherCAT with all TruLaser Cell machines because it provides an optimal fieldbus system for modular control cabinet equipment. The EK1914 EtherCAT Coupler combines standard functions with secure digital I/Os in a compact design, which can be expanded to include additional EtherCAT Terminals as needed. Using the EtherCAT I/O system, we significantly reduce the space required in the control cabinet compared to other fieldbus systems.”

Brauchle also values the extensive EtherCAT diagnostic options as a means of locating the causes of faults. For example, in one case study a service technician remotely identified a fault in a cable for the power supply: After the right spare part was received and replaced by the machine user, the system was back up, running smoothly again and the customer was impressed with the service.

Demanding requirements on the machine HMI

Trumpf machine control panels have extremely demanding requirements, which ultimately led to the decision to use a customised control panel from Beckhoff. Brauchle elaborates: “On one hand, the HMI has to be uniformly suitable for diverse machine technologies. While on the other, our demands regarding ergonomics and design must also be fulfilled. This is only possible with a specifically developed control panel. Beckhoff’s high flexibility regarding the design was a particular advantage. For example, we were able to specify the supplier for the integrated pushbuttons. We also quickly received a fully functional prototype for our own testing.”

Openness and system safety

A wide variety of fieldbus systems needed to be considered, given that Trumpf’s OEM customers integrate the laser sources into production lines. According to Brauchle, Beckhoff’s PC-based control combined with a range of different fieldbus controllers, enable the machines to adapt to each production environment. For example, Profinet is connected via the EL6631 terminal, as well as EtherNet/IP (EL6652), DeviceNet (EL6752) and Profibus (EL6731).

Machine safety is also integrated consistently across diverse TwinSAFE Terminals and Box modules. Brauchle concludes: “TwinSAFE replaces electromechanical components with wear-free software. This has significantly reduced the number of conventional components and the amount of wiring required. All non-drive safety functions were implemented via the TwinSAFE Editor and we truly value its graphical overview of the logical links. The ability to show and hide safety functions is essential for standard machines with expansions.”

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved