Hundreds of thousands of people left without electricity as global supply chains screech to a halt. These are just two of the potentially devastating effects cyberattacks could have on critical infrastructure and manufacturing in the future. In fact, the past ten years have seen more cybersecurity incidents involving industrial control systems than ever before.

In the Industrial Internet of Things (IIoT) era, previously unconnected systems are now connected over private or public networks in order to gain more insight and improve productivity. However, with greater connectivity comes greater exposure to cyber threats. So how do we keep the world’s critical infrastructure and manufacturing environments safe from cyberattacks?

Today, nearly every critical network or manufacturing environment is connected to the Internet and exposed to cybersecurity risks in some way. In fact, cyberattacks targeting critical infrastructure and manufacturing environments around the world are becoming more frequent.

With so much at stake, it is little wonder that national governments and industry organisations around the world are beginning to heed the call to address cybersecurity vulnerabilities, in both industrial networks and critical infrastructure.

Industrial Network Defence Solution to overcome modern-day industrial cybersecurity challenges

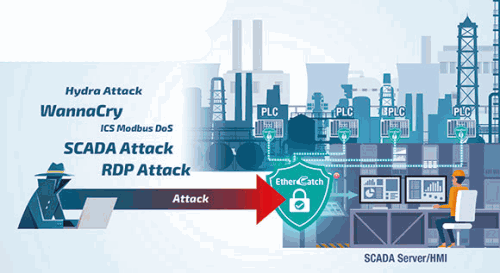

Moxa, a leader in industrial communications and networking, has introduced its Industrial Network Defence Solution, which is specially designed to secure industrial networks from both the operations technology (OT) and information technology (IT) perspectives, to better address the surging market demand for a comprehensive cybersecurity solution for industrial networks. Moxa’s Industrial Network Defence Solution includes critical IT cybersecurity technologies such as an Intrusion Prevention System (IPS), a key component for defence-in-depth strategies, which has been specifically tailored to protect OT networks from cyber threats without disrupting industrial operations.

As system availability is often the most important consideration for OT systems, network operators are seeking a more effective and lower-impact approach, to prevent operations from being affected by cyber threats and attacks while ensuring maximum system availability. Nowadays, the prevalence of cybersecurity incidents has urged governments to pass laws that require industries such as power, energy, transportation, and critical manufacturing to implement cybersecurity countermeasures into their industrial control systems, especially for critical network infrastructure. Furthermore, companies in the manufacturing sector have started to enhance the security of their industrial networks to avoid loss of revenue or damage to their reputations. To that end, industrial network security has become a major concern that has driven OT and IT departments to work together to find a holistic solution.

Having foreseen the rising demand for industrial network security, Moxa has devoted significant resources towards developing industrial networking devices, such as secure routers and Ethernet switches, with enhanced security features based on the IEC 62443 standard. In addition to this, Moxa has developed the Industrial Network Defence Solution, which includes IT technologies such as an Intrusion Prevention System (IPS) as well as an Intrusion Detection system (IDS), and their specific approaches for use in industrial applications. This allows customers to detect and prevent any malicious network behaviours that occur either inside OT networks, or from the Internet.

Moxa’s Industrial Network Defence Solution includes industrial IPS/IDS, industrial next-generation firewalls, and security management software, which collectively provides:

• Advanced network protection.

• OT-IT integration.

• Centralised security management.

“Moxa is devoted to developing our connectivity product portfolio with built-in security features for our customers to develop secure network infrastructure,” said Li Peng, product manager of Moxa’s Industrial Network Security business unit. “With a solid foundation in industrial networking, our new Industrial Network Defence Solution has brought a holistic OT-IT security platform to our OT customers. We will be continuously developing our solutions to meet user demands across various industrial applications.”

About Moxa Industrial Network Security

With an ongoing commitment to protecting the connectivity of industrial environments, Moxa has invested in developing security hardened networking devices, including secure routers and Ethernet switches. In light of the increasing cyber threats facing industrial networks, Moxa has enhanced its network security portfolio with the Industrial Network Defence Solution, which was co-developed with its technology partner, TXOne Networks. The purpose of this joint venture between Moxa and Trend Micro is to utilise the best of Moxa’s OT experience and Trend Micro’s IT experience, to build advanced technologies that help accelerate the transition of the industrial world to secure automation architectures.

Checklist for industrial cybersecurity

Moxa has compiled a checklist to ensure that no defence-in-depth security measures get forgotten.

Secure devices

• Identify and control who can log in to devices.

• Increase password complexity to enhance access control.

• Verify authorised devices before they gain access to the network and communicate with other devices.

• Encrypt confidential serial interface data to ensure integrity.

• Encrypt configuration data to increase confidentiality.

• Select device vendors that respond quickly to reported vulnerabilities and fix them.

Secure network infrastructure

• Segment large-scale networks into smaller networks to avoid networking issues interrupting operations or bringing the entire network to a halt.

• Filter out unauthorised packets and block unauthorised access to enhance access control.

• Create a secure tunnel for encrypted data transmission to ensure data integrity.

• Deploy industrial firewalls, VLAN or ACL, which are the most feasible and cost-effective options for industrial control systems.

Security management

• Create security policies that meet your network requirements.

• Ensure all network devices are configured to the same security level.

• Continuously scan the security status of devices to ensure the whole network is secure.

• Regularly monitor the network to see if any new devices were added.

• Save all event logs for reference in the event of a security breach.

• Compare the network configurations before and after incidents to find the root cause of the problem.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved