The line triangulation method is a frequently underestimated sensing mode for monitoring presence, completeness, position, and similar tasks. In many applications, compact intelligent light section sensors deliver results that are more precise and reliable than those delivered by other types of sensors. Line triangulation technology is not only unaffected by extraneous light, it also reliably detects objects with minimal contrast or no contrast to the background. The potential of the line triangulation method will be demonstrated using a number of application examples from different industrial fields and sectors.

Light section sensors combine all the required components in one compact device and are usually easier to parameterise than 2D vision sensors. They work on the principle of triangulation, using a projected laser line to detect height profiles and edge contours with high precision: the known distances and angles of the triangle formed by the light source, camera, and object are used to calculate the exact positions of all points along the line projected on the target object.

Precise and resistant to interference

The use of a sharply defined laser beam provides some decisive advantages when compared to normal vision sensors. Light section sensors can clearly detect low-contrast objects and even zero-contrast objects. They only require differences in height to detect surfaces. Furthermore, the light section method is much more resistant to extraneous light and fluctuating lighting conditions. In 2D vision sensors, (unexpected) changes in lighting in particular can dramatically reduce or even completely disable detection performance, for instance if daylight enters a window. When using vision sensors, the exposure time, arrangement of the device, and, where necessary, external lighting must always be precisely adapted to the conditions of the application. In contrast, the automatic exposure time control function with which light section sensors are ideally supplied is perfectly sufficient for the vast majority of applications.

Packaging technology

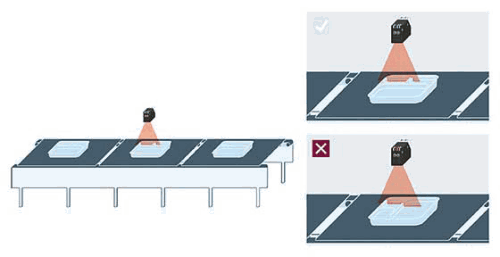

The discussed properties predestine high-performance laser-line triangulation sensors, such as the SmartRunner Matcher from Pepperl+Fuchs, for use in numerous applications in the packaging technology sector. For instance, plastic trays with multiple compartments are often used to package ready meals. These allow the main course and side dishes to be kept separate until consumed for reasons of taste and aesthetics. Proper separation of the components is a prerequisite for customer acceptance as well as for correct, air-tight sealing. Therefore, it is necessary to check the orientation of the trays before filling. Here, too, the light section sensor can prove its worth, as the plain, mostly white trays naturally offer only little contrast. The Matcher always delivers reliable and unambiguous results by detecting the height profiles.

Ready-to-use line triangulation solution

Laser-line triangulation technology is often superior to other solutions and has much untapped potential that users should exploit in their applications. All of these applications can be implemented with the SmartRunner Matcher laser-line triangulation sensor. This Pepperl+Fuchs device combines a high-precision light section sensor and a vision sensor in one compact unit. The Matcher is factory-optimised to recognise a previously learned reference contour, can store up to 32 profiles, and can be integrated immediately into applications as a plug-and-play solution. The evaluation results are output via switching outputs as ‘good’ or ‘bad’ signals that any control panel can process. Fieldbus solutions and gateways are also available for Profinet, Profibus, EtherNet/IP, and EtherCAT.

One interesting feature is the option to output the deviation of the current position from the learned X and Z positions. If an application does not allow accurate triggering then standard sensors such as light sensors or ultrasonic sensors are not suitable for presence detection. In this case, laser-line triangulation sensors can deliver geometric displacement results to the control panel. A powerful LED lighting system is also integrated for generating image documentation of faults, process states, and quality characteristics. Alternatively, the sensor can be easily parameterised using Data Matrix control codes, so that no PC is required.

| Tel: | +27 10 430 0250 |

| Email: | [email protected] |

| www: | www.pepperl-fuchs.com/en-za |

| Articles: | More information and articles about Pepperl+Fuchs |

© Technews Publishing (Pty) Ltd | All Rights Reserved