Industrial control systems are known to be expensive and complicated to deploy and use. Not only is the hardware expensive, but the software is also often costly to run and maintain. With many vendors now coming into the market with cost-effective solutions, not all provide features comparable to the well-known brands, and even fewer provide enhanced features to include seamless IIoT integration.

System integrators faced with the decision of which hardware platform to use should consider the following five factors:

1. Ease of use

A major factor when choosing a platform for the control system is ease of use in the required application. When engineers decide on hardware and software solutions they need to use something familiar and easy to learn and use. The less time engineers spend learning a new platform, the quicker the solution can be built. The most difficult aspect of any control system is getting to grips with the software. It is therefore vital to use software that is familiar and includes all the relevant programming languages familiar to control system engineers and system integrators.

2. Familiarity

Ease of use and familiarity go hand in hand, as the more familiar the product, the easier it is to get the best out of it. PLCs and scada systems use a wide variety of communication protocols to establish reliable and deterministic communication channels between remote I/O, PLCs, HMIs and scada. Making use of familiar, tried-and-tested protocols such as Modbus, Profinet and Ethernet/IP greatly increases the efficiency with which engineers can integrate control system solutions.

3. Interoperability

Devices in control systems need to integrate seamlessly to make the solution cost effective. When engineers are planning and designing control systems, most new platforms include a decentralised design to save on wiring cost for the inclusion of remote I/O stations. These systems include a ‘head’ module with networking and addressing capability, in addition to the I/O which provides the physical inputs and outputs for control.

4. Cost

As mentioned earlier, cost is a major consideration when choosing a control system platform. Not only the hardware cost, remember that the programming and visualisation can also drive up the cost of the overall solution. Other costs that need to be considered are the cost of downtime due to faulty I/O or controllers, and other costs relating to the maintenance of the control system. Training costs should also be considered.

5. Expandability

The value of being able to expand and upgrade a control system is often underestimated. A seemingly trivial task like adding remote IO to an existing system can sometimes become quite complex and difficult to achieve. Having hardware and software that eases this process can greatly influence the choice engineers make when choosing their preferred control system.

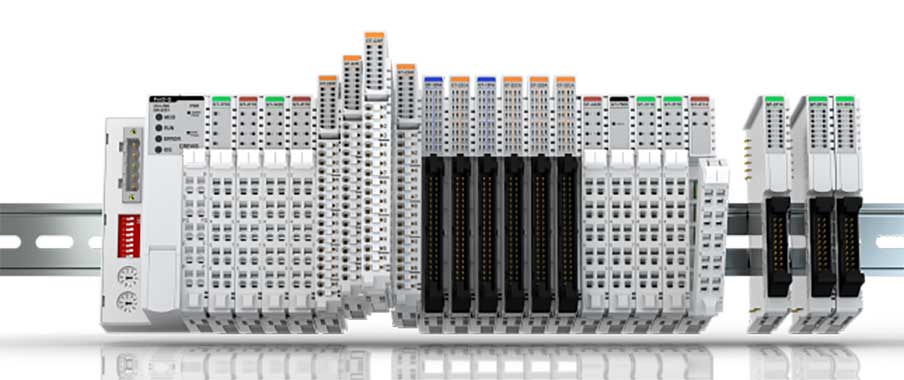

Crevis’ remote I/O and PLC solutions

With Crevis’ unique hardware and software solutions, the choice is made easy for system integrators and control system engineers through unique and user-friendly designs for remote I/O and PLC solutions. Features include easily removable terminal blocks to avoid rewiring entire I/O modules when replacement is needed, while the slice card mechanism makes adding and removing cards easy.

The system uses familiar industrial programming software from Codesys. By developing a variety of network adaptors, Crevis offers a cost-effective remote I/O solution. These remote I/O network adaptors can easily be integrated into many existing automation systems, thanks to the support of up to twelve of the best known industrial communication protocols, such as Modbus, Profibus, Profinet, Ethernet/IP, CC-Link and EtherCAT, to name a few. By using Codesys, Crevis can also utilise the built-in web-visio platform to build a complete scada system into its PLC controller, eliminating the need for third-party scada systems.

The ability to upgrade is also easily accomplished. By simply changing the network adaptor of a remote I/O station, system integrators can easily change from one PLC vendor to another without needing to change all the remote I/O stations. Crevis provides a cost-effective approach to remote I/O and programmable controllers, which integrate seamlessly with other PLC vendors. The use of Codesys greatly reduces the cost of ownership, and enables greater flexibility than was ever available from legacy systems of the past.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved