This article will discuss the two classes of processes called self-regulating and integrating (or ramping) processes. This subject is absolutely vital to regulatory control, but strangely is seldom taught on control courses. In fact, there are very few instrumentation and control personnel who have even heard of this subject.

From the control point of view, every process falls into one or the other of the two classes. They behave, and are tuned, very differently, and it is essential that one fully understands the difference if successful optimisation is to be achieved.

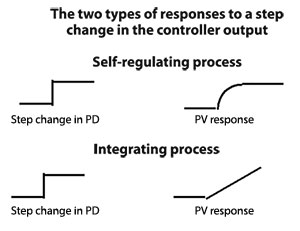

The two response types

Figure 1 illustrates the basic difference in responses between the two classes of processes. Self-regulating processes are characterised by an open loop response to a step change that rises or falls to some new and constant value after the loop dynamics have died out. Integrating processes are characterised by an open loop response to a step input change that ramps continuously at a constant rate after the loop dynamics have died out.

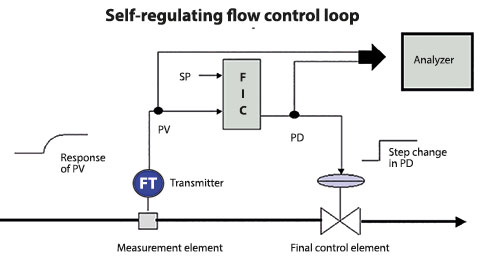

A typical example of a self-regulating process is the flow process shown in Figure 2. The process variable (PV) effectively follows the movements of the process demand (PD).

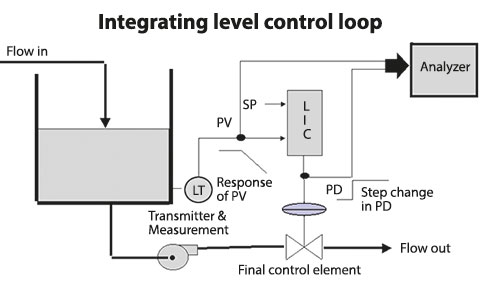

Integrating processes, however, which are typified by level control processes as shown in Figure 3, have a very different relationship between PD and PV.

All integrating processes rely on balancing the input and output of the process to keep the PV constant. In the case of the level control, the PV remains constant when the PD has the valve at such a position so that the flows in and out of the tank are equal. When this condition exists, the process is said to be balanced, and the PD and actual valve stem position are said to be at the balance point.

If the PD is stepped away from the balance point, the inflow and outflow will now differ, and the level will either move up or down, as the case may be, in the form of a constant ramp. If the PD is left at the same place, the ramp will continue until the tank empties, or overflows.

This means that an integrating process is inherently unstable, because if left in manual, the balance point will change sooner or later due to load changes, and the process will tend to ‘run away’. Therefore integrating processes cannot be left unattended in manual for too long, and in fact, must really be controlled in automatic. Self-regulating processes, on the other hand, are inherently stable and can be left in manual.

In view of this, one could query why self-regulating processes need to be controlled at all. The main reason that controllers are used for the vast majority of such processes is to cope with load changes. (Load changes can be defined as a change in conditions external to the loop causing the PV to change and to move away from set-point). Of course in some cases the controller is there to make the process follow set-point changes.

Some processes are difficult to categorise

It can, in certain instances, be very difficult to decide to which class a process should belong, as some processes appear to be both integrating and self-regulating. For example, take the case of a level process similar to that illustrated in Figure 3, but without the pump at the bottom of the tank. Such a process is referred to as a ‘gravity fed’ tank. If the level in this tank was in balance and the control valve was then opened a bit, the level would then start ramping down in the typical integrating fashion. However, as it drops, the hydrostatic head above the outlet pipe would decrease, thus causing the flow to decrease as well. The ramp rate would also decrease, and eventually if the valve had not been stepped too far, the level would balance itself out again, before the tank emptied. The response on the PV would actually look, in the long term, like a self-regulating process.

So what class of process does it actually belong to?

The rule of thumb is: you tune a process the way it starts reacting. So, if a process starts out as integrating (like the gravity fed tank), and then turns into a self-regulating process, you tune it as an integrating process. If it starts out as a self-regulating process and then becomes integrating, it is tuned as a self-regulating process.

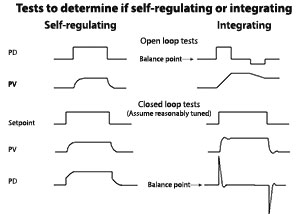

Other rules of thumb are that flows are always self-regulating, and levels integrating. One exception on levels is controlling the head over a weir, which is self-regulating. It can sometimes be quite difficult to decide into which class of process pressures and temperatures fall. One way to decide is to look at the response of the processes to changes when the loop is in manual or in automatic. Typical responses are shown in Figure 4.

The importance of understanding the subject cannot be over-stressed if you wish to successfully optimise control of processes. Most people have a basic feel of how self-regulating processes operate, and how to go about tuning them. However, in general, very few people have any understanding, and even more importantly, any feel, on how to tune integrating loops.

In most plants I go into the integrating loops are in a shocking state, being so badly tuned that they exhibit very slow cyclic responses to set-point or load changes. Many are in a continuous, very slow cycle. I was quite amused recently, when after an in-plant course in one of South Africa’s largest petrochemical refineries, the chief control engineer, a man with high qualifications and many years of experience behind him, admitted to me that the section on optimising integrating loops had been a real eye opener to his staff and to him, and that he now agreed that probably not a single one of the many hundreds of level loops in his plant had been tuned correctly.

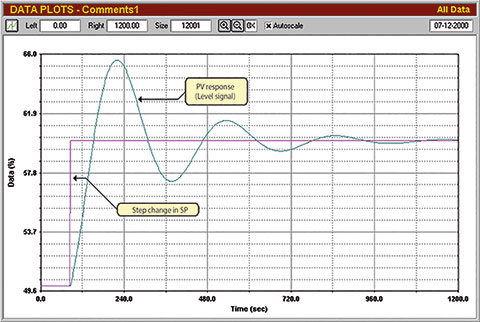

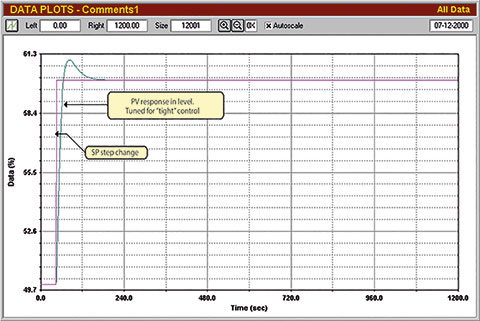

Figure 5 illustrates a typical example of an ‘as found’ level control response to a step change in set-point, and Figure 6, the response on the same loop after proper tuning for ‘tight’ control. It should be noted that not all levels are tuned this way, as in some processes the level control is detuned to prevent the control valve from moving around too much, but this is the subject for another discussion.

Michael Brown

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering.

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved