Control loop optimisation has always fascinated me. In most cases when I am called into a plant to sort out a problem, it is something that they have been trying to fix for a long time without success. Therefore these problems are usually very challenging. Many years ago the chief control engineer at a large plant in South Africa, said he thought I must be completely crazy doing this kind of work. He said that in his opinion, clever people in most plants who know their processes backwards would have been trying to solve their problems for quite a while, and how could I go into these plants with no prior plant knowledge and try and fix the problem in a short space of time?

He certainly has a point. You have to go into the plant and try and analyse the problem, which usually involves having to learn all aspects about the control, ranging from learning the process, the control strategy, through to trouble shooting all the components in the control loop. It certainly makes life extremely interesting.

I am frequently asked as to what is my success ratio. Generally I would say that I can solve problems in the vast majority of cases. However, due to the nature of working plants, the solutions often cannot be implemented immediately. For example, sometimes it cannot be fixed until the next shut-down, or in the case of valves (which generally are the cause of most control problems) it has to wait until the valve can be serviced or replaced. Also, in most plants, instrument maintenance personnel have to be scheduled to work on the offending equipment at a later date. Problems that require changes in programming in the control equipment, such as modifying the control strategy, or reprogramming a controller, can also not usually be performed until permission has been obtained from higher authorities, which often involves all sorts of meetings, safety evaluations, etc.

There are always exceptions

Unfortunately, one cannot always be successful. For example, there are occasionally cases where analysis cannot be performed due to loop instability of one sort or another. It is generally vital to get steady state conditions to do analysis and tuning, but with some processes it seems impossible to achieve, as conditions are always changing. There have been occasions where we literally have spent days on trying to stabilise a particular process without success. Generally with these processes it is back to ‘trial and error’ tuning which is very unsatisfying.

Then there are also processes that cannot be controlled with conventional feedback control systems, and possibly not even by more advanced systems.

On very rare occasions, one also encounters process phenomena for which no logical explanation appears to exist. Things happen in a process for which no one can give a rational explanation. At times, these things seem to defy the laws of physics. I have attended many discussions with plant control and process experts trying to find out why these things are happening. Obviously it is generally impossible to fix something that cannot be understood.

The interesting thing is that the plant operators, even in the face of apparently insurmountable control problems, still manage to run the plant and make product. I have talked about process operators before and have mentioned that even though the majority in most plants are not highly qualified people, they still develop empirical skills through long experience of running the plant. I do believe that the performance of operators is often not recognised properly, and they are not given sufficient credit by management for their performances.

However, fortunately as mentioned above, the vast majority of problems I investigate are fixable, and it gives you a feeling of tremendous satisfaction when a problem is solved and the loop is working nicely. This is why I have persevered in this job for so many years.

Positive lead integrators

When it comes to optimisation, there is one type of process which, if tuned correctly, gives one the most satisfaction. This is the ‘positive lead integrator’, a process with dynamics which very few C&I practitioners understand. I have written about this quite a few times in the past, but I always think it worthwhile giving examples of these when one encounters them. They are normally tuned very badly and extremely slowly, and if one understands the dynamics, they can then usually be tuned very much faster and more robustly.

Drum pressure in a petrochemical refinery

I recently encountered an example when optimising the drum pressure in a petrochemical refinery. The operators were complaining that firstly, when there was a load change, the process never got back to setpoint and they always had to get it there in manual. Secondly, they said that the control itself was very slow to respond to changes.

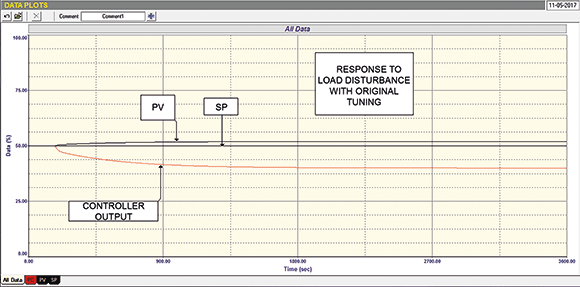

Figure 1 shows the response of the process to a load change with the ‘as found’ tuning, which was P = 5 (gain), and I = 0 repeats/minute. (Please note that the closed loop tests illustrated here were done by accurate simulation using the process dynamics captured by the Protuner. This is because it is very much easier to simulate a load change than to make one on the actual process, which normally upsets production.)

One can see in the Figure that the PV never gets back to setpoint. The reason for this is because the tuning was for a proportional only controller with no integral. With a proportional gain of 5 and no integral, there is a possibility that offsets of as large as 20% could be encountered! Integral is the term in the control that is there to get rid of offset.

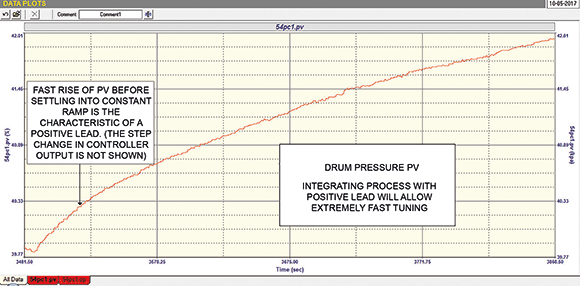

Figure 2 is the actual open loop test and shows the PV response when subjected to a step change in the controller output with the controller in manual. (It is important that when one is performing the test that you initially get the process to steady out.) As can be seen in the test, the process is very much an integrator. These always require one to get the process into balance to reach steady state which can only occur when the input and the output of the process are equal (known as a balanced process).

The significant thing in this particular process is that instead of the PV going into a constant ramp immediately after the step change on controller output was made, as one sees on level controls, there is an initial fast rise in the PV. This can be clearly seen in the Figure. What is actually happening here, is that the process initially acts as a self-regulating process, which occurs as the input to the process initially changes. However, as the pressure in the drum increases the vapours start compressing, which acts in an integrating fashion.

We refer to this type of dynamics as ‘a positive lead integrator’.

The correct way to tune such processes, which have a significant lead, is to tune on the self-regulating part of the process, and not on the integrating part. This usually results in a very much faster tune, which in turn allows the controller to deal with the change immediately on the self-regulating bit, before it starts integrating.

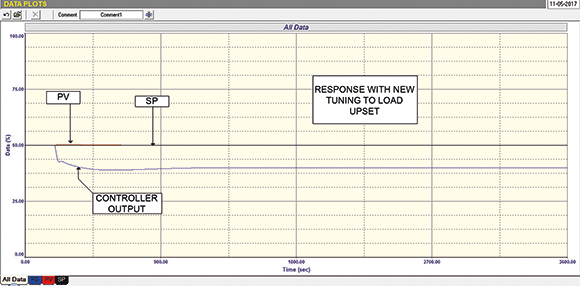

In this case, the Protuner gave a tuning of P = 8 (gain), and I = 18 repeats/minute.

Figure 3 shows a final test with the new values. Comparing this with the original closed loop test shows just how remarkably well this new tuning works – almost magically.

I often refer to this tuning as a ‘party trick’. Usually, using it gives dramatic results compared with the original tunings. As very few people seem to be aware of how to deal with a positive lead integrator, they tend to tune them very slowly since they can become unstable if tuned incorrectly. On one auspicious occasion, when tuning the dryer steam pressure on a paper machine, we improved the speed of response by some 2000 times which equated to a considerable improvement in productivity on that particular plant.

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering, +27 (0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved