Introduction

Driving down the operational cost of process installations across different industries and markets by using more sophisticated automation systems and applications has been an ongoing process for years. An important part of this has become the tendency of unmanning and remote operations of process installations and to investigate for which applications new technological developments allows this to be realised in a safe and cost effective manner. Today’s scada systems are perfectly positioned to facilitate the technology, infrastructure and functionality to achieve these aims.

Modern scada systems rely to a large extent on new IT technologies embedded in their core software architectures. Despite the many advantages of these new technologies, they also present a higher risk as they are often more susceptive to cyber attacks than rigid proprietary software. On the other hand, they do facilitate a cost-effective integration of environmental monitoring and intrusion detection systems.

This means that scada software for automation and integration of geographically dispersed process locations in particular should be adaptive to emerging new IT technologies as well as to the latest ‘best in class’ security solutions that are available. This allows scada system vendors to concentrate their R&D efforts on the functional requirements of user specific automation applications and optimisation needs. To make this possible, today’s scada systems for process automation and remote operations should at least be independent of the hardware platform and communications media used. They also need to have access to a ‘state-of-the-art’ web-based visualisation environment and associated highly secure network infrastructure and web services. This will secure their key role in facilitating the seamless integration of any brand control and monitoring systems.

For these reasons, there is a bright future for any scada system that has a truly web-based visualisation environment and makes optimal use of available IT technologies. Such a system will bring end-users more intuitive and advanced visualisation and rapid deployment of their process mimics, alarm, trend and report overviews. Furthermore, it makes it easier to maintain and integrate information from different information sources in one graphical ‘dashboard’ with role-based key performance indicators (KPIs). In this way, information can be shared with authorised user groups in a secure way across geographically dispersed locations. This enables operators to monitor the operational condition and performance of all their assets from any location with secure Internet access at any time through a single-window web-browser environment.

This article outlines some of the emerging technologies that relate to such scada systems and their applications. It provides a perspective on efficiency improvements that can be achieved through a truly web-based scada infrastructure, as well as describing how the utilisation of a web-based infrastructure can be taken a major step further by the use of dynamic layering and visibility techniques.

Web deployment of scada visualisation

The benefits and potential cost savings that can be achieved through a secure web-based scada infrastructure can be significant. A true web-based server and client architecture which is loosely coupled with the operating system provides easy remote access and security enhancements for deploying reliable graphic and application services via the web. For example, to support an organisation’s security policies, scada systems and their applications must be hardened to protect them against unauthorised usage and access. The transparent nature, independency and flexibility of web technology makes it easy to adapt to the most advanced IT security techniques.

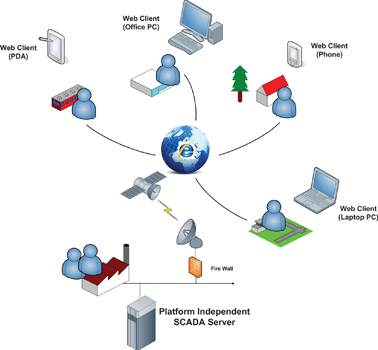

Furthermore, platform independence of web-based scada systems is important to make them sufficiently flexible to run on computer devices with different operating systems in order to increase accessibility and maintainability across the system and to secure previously made application investments. This can be achieved by using Java as the core software technology, which makes the scada client environment available as an independent application or as an applet in a web browser or on other devices such as Java phones, PDAs or iMacs. The availability of modern telecommunications technology means that physical barriers can easily be removed, and information can be accessed in a flexible way. Specific user groups (management, finance, operations, logistics, maintenance etc,) can be served with information for their particular interests and needs (Figure 1).

Web-enabled Web-based

It is important to emphasise that ‘web-based’ is not the same as ‘web-enabled’, the latter describing software where often only a limited part of its functionality is made available through a web portal on top. Truly web-based scada systems are designed and built to run completely in a web environment which allows access to all functionality of the scada system with only browser technology at the desktop level. Such systems offer increased responsiveness and interactivity – achieved by exchanging small amounts of data with the server ‘behind the scenes’. The only information exchanged is that associated with the role and specified area of interest of a particular user.

Another cost reduction that can be achieved by utilising web technology is installing and maintaining the scada visualisation environment on remote clients over the system communication infrastructure. This functionality is called zero deployment (Figure 2). Zero deployment is designed to simplify and enhance the distribution of applications to users (clients). Zero deployment means that users do not have to request or download the application, because it is automatically delivered from the scada server at first identification and log-on. The next time a client logs on he receives only the updates and stays continuously current with any application/configuration changes.

The processing power to run the client applications causes a limited amount of additional load on the server as they are executed locally using processing power from the client PC. Many more clients can be easily served in this way through one web server compared to what can be achieved using a terminal server.

Zero deployment means that client applications can be automatically obtained via any web browser by authorised users, with users always getting the most recent version of an application. There is no need to manage licenses and software installations on the client side, no application files to copy over, and no communication configurations to setup. The organisation benefits from better load sharing between server and clients, as well as the ability to use IT approved security and secure network connections.

Web-based server/client architectures provide easy remote access (Figure 3), and therefore security enhancements and precautions to reliably deploy graphics and application services via the web are mandatory. Fortunately, truly web-based scada systems are perfectly positioned to leverage standard and proven web security techniques as administered by IT departments, such as network-centric computing (for example Citrix XenApp) or VPN tunnelling token and username/password (level 2 security).

Built-in endpoint scans and policy controls should take into account each user’s role, device characteristics and network conditions to determine which applications and data they are authorised to access. Benefits of this approach include:

* Secure application delivery.

* Lower TCO (total cost of ownership).

* Increased IT productivity.

* No unauthorised access.

* Qualitative data encryption.

These advanced and secure web-based visualisation technologies allow end-users to cost effectively share operational and integrity information across the enterprise without jeopardising application security and maintainability (Figure 4).

Dynamic layers, zooming and panning

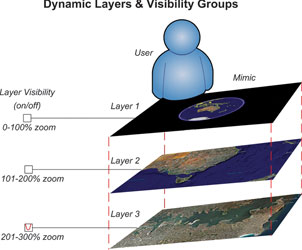

This technology also allows process mimics to be built up with dynamic layers and backgrounds – including pictures and process drawings, for example – that can independently be made visible and/or transparent in the web-based operator environment (Figure 5). These layers can be triggered by process conditions, by manual controls or by user login privileges. As a result, multilevel process supervision and KPI monitoring can be carried out within one operations environment.

This approach allows for the logical separation of different types of operational and maintenance information in a structured manner. The layers can be turned on or off depending of (process) conditions. It is possible, for example, to design the process flow diagrams in one layer, detailed instrumentation in a second layer, electrical power distribution schemes in a third layer and so on.

It is also possible to authorise different users to see and/or access specific layers as controlled by the scada software. Details can be turned on and off according to triggers generated from security settings, process conditions and zoom levels. This means that it is possible to visualise only that information that is relevant to a specific user, with resulting improvements in operational efficiency and the reduced chance of errors because there is no need to rebuild displays for each domain expert.

Other benefits include the fact that specific information for operations, maintenance, planning, scheduling, logistics and finance can be covered by distinct layers within one HMI environment.

Information content on one mimic can be made very rich without jeopardising operator ergonomics, and visualisation groups can be defined for ‘clutter/de-clutter’ zooming and panning areas. This is a similar concept to the Google Earth style of zooming and panning, where details become visible depending on the display zoom level. Zooming and panning can be fast and smooth, being continuously variable with no need to open different windows to increases performance.

Distinct layers can be linked to specified zoom levels, allowing, for example, an operator to see only those layers with information and sufficient details that are associated with the zoom level of the specific process area of a plant being monitored. It becomes possible to draw entire process areas and plants in one large operator mimic, which could also fit on a large video wall. The operator can then zoom in on specific details by means of the continuously variable zoom factor, while simultaneously seeing an overview of the entire plant or process and detailed views of specific areas and units. This technique also allows for application-specific GIS Functionality, with maps being imported and assigned to different layers in operator mimics.

Conclusion

Web-based scada visualisation will bring changes in the realtime presentation of information intelligence, enabling an evolution to a much more intuitive and advanced approach in process management featuring visualisation and associated dashboard views. It will also make it easier to adapt to and to utilise application security and deployment techniques. These client/host web-based architectures should be able to run on any operating system platform to reduce R&D cost for operating system specific upgrades. Dynamic layers and visibility groups enable multilevel process and KPI monitoring and supervision within one operating environment.

The results of adapting the technologies discussed in this article will reduce operating faults, cut development time, and minimise maintenance costs.

| Tel: | +27 11 831 6300 |

| Fax: | +27 11 86 411 8144 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved