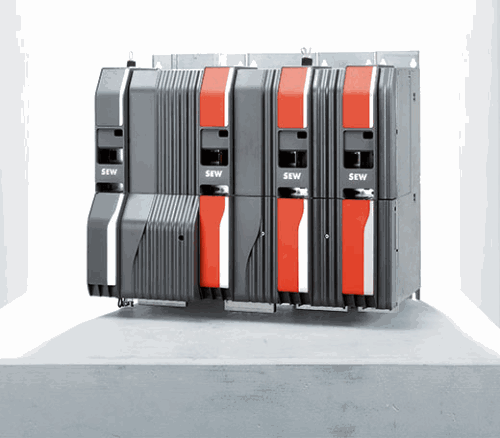

MOVI-C comprises four components: MOVISUITE engineering software, MOVI-C Controller control technology, MOVIDRIVE inverter technology, and MOVIGEAR, MOVIMOT decentralised drive technology comprising the company’s flagship range of mechatronic drives – which includes gear units, motors, electric cylinders, brakes, built-in encoders and diagnostic units. Together these components form one end-to-end modular automation system and can be combined to suit any bus topology.

Maxolution engineer, Dylan Enslin, says that a key change from SEW-EURODRIVE‘s Generation B range is the uniformity of the look and feel of these newly developed products and software across the range, which, building on previous generations, greatly improves the user interface. “The new MOVI-C designs are different but the actual interface is the same across the range. They also have a whole lot of new features, and will be phased in gradually, starting with the popular sizes,“ he explains. “In essence, MOVI-C combines the advantages of decentralised installation – saving space and lowering costs – with the flexibility of SEW-EURODRIVE’s modular portfolio.”

Free communication across topologies

All components of a MOVI-C system can be fully integrated into any automation design, fieldbus topology or network standard. There is complete freedom of configuration, as MOVI-C is compatible with protocols from Profibus and Industrial Ethernet through to Modbus. ”With Generation C, Profinet is included as an onboard option on the decentralised products,“ adds Enslin. “This has opened doors and is a huge benefit to customers as it simplifies the installation and programming.“

MOVI-C applications can draw on a variety of configurations. Examples are single-axis automation in materials transportation; motion control in multiple column hoists, tripod mechanics and robots; module automation in packing and processing machines and complex transportation tasks; and functionality as an EtherCAT motion slave in series machines with numerous axes and kinematic calculation in high level PLC, with EtherCAT CiA402 also available as an integration option.

Functional safety

SEW-EURODRIVE‘s MOVISAFE safety cards have made functional safety an integral part of all MOVI-C inverter applications. Higher level safety functions are achieved by inserting an option card connecting to the inverter technology – encoder, communication and STO. Costs are thus reduced to only the function actually needed. Enslin says that this is a vast improvement on Generation B and makes it easier to get a machine up and running quickly in the event of a breakdown.

Faster and simpler

The MOVISUITE engineering software allows quicker and simpler planning, commissioning, operation and diagnostics, reducing costs for users while improving usability. MOVI-C Controller allows more freedom for parameterisation, with less programming and centralised data management for greater simplicity – thanks to the ready-standardised MOVIKIT software modules. The end result is reduced cost and complexity.

Single-cable technology with a digital encoder for synchronous and asynchronous AC motors is another big improvement. Now only one hybrid cable is required for the data and power connection between the frequency inverter and electric motor. A further innovation is the new digitaL MOVILINK DDI data interface, which sends performance, brake and diagnostic data from the motor.

Customisation for clients

“What this means for our clients is that everything looks completely new, but is simpler, easier and more user-friendly. The revamped software has been optimised, with improved electronics on the component level,” Enslin explains. “With Generation C we have improved control, higher efficiency and more features, as well as added flexibility in applications. Everything is modular and decentralised. Our aim is to service customers more efficiently and effectively, and be able to provide each with a fully modular and customisable solution.”

The road ahead

“Looking to the future, SEW-EURODRIVE has embarked on an exciting new project – the construction of a new R200 million head office and factory to accommodate its phenomenal growth. The approximately 25 000 m2 building is situated alongside the company’s existing 5000 m2 headquarters in Johannesburg . “We are on track to take occupation in early 2022,” he adds.

The high-tech facility will accommodate existing assembly plants, as well as the new MOVI-C facility, in order to improve efficiencies and contain costs. The factory will be automated, with state-of-the-art equipment ready for Industry 4.0.

“SEW-EURODRIVE is very fortunate to be diversified, with markets spanning mining, food and beverage, and automotive, so we can still function no matter the challenge. These figures tell the story and put our growth into perspective,” Enslin concludes.

MOVI-C, MOVISUITE, MOVIDRIVE, MOVIGEAR and MOVIMOT are registered brand names of SEW-EURODRIVE.

| Tel: | +27 11 248 7000 |

| Email: | [email protected] |

| www: | www.sew-eurodrive.co.za |

| Articles: | More information and articles about SEW-EURODRIVE |

© Technews Publishing (Pty) Ltd | All Rights Reserved