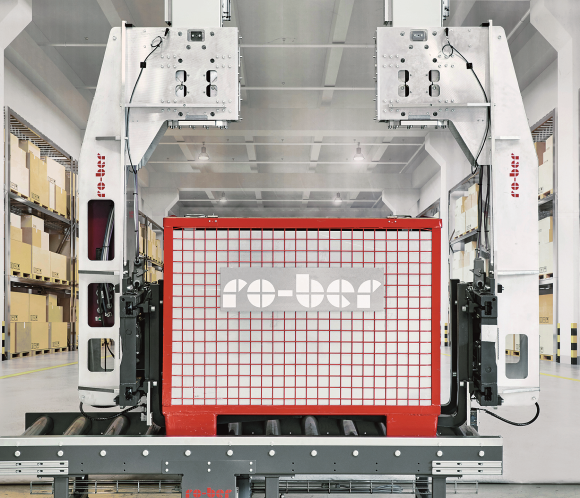

RO-BER Industrieroboter of Kamen, Germany, develops automation solutions based on area and linear gantry robots for intralogistics. These solutions, including the new Twin-Gantry robot system, are characterised by high performance, reliability and flexibility. As a highly scalable control and drive platform, PC-based control forms the ideal basis for solutions that can be tailored to individual application requirements. In addition, the system supplier benefits from the universal integration of PLC, CNC and safety functionality in PC control technology to implement diverse system architectures.

Another reason for the switch to Beckhoff was the high performance of the communication technology, first, because EtherCAT is a fast bus system and second, because it facilitates the implementation of many different topologies. There is another aspect, according to RO-BER’s managing director, Elmar Stöve: “What was really important to us was the system philosophy on the one hand and the control system openness on the other. With the EtherCAT Terminal portfolio, PC-based control from Beckhoff covers an extremely large range of applications, which means that there is a choice of one or even several I/O products for almost all electrical or communication-related tasks. Above all, when it came to electromechanical components such as pneumatic components, we greatly appreciated the easy integration of third-party devices via EtherCAT as well as via CAN, Profinet or other protocols. In addition, Beckhoff gave us great support from the outset and even integrated new functions into TwinCAT that are important for our application.”

Control technology as an innovation driver

Safety technology can also integrate seamlessly into the I/O system with TwinSAFE terminals. Stöve explains: “In this way we were not only able to reduce the wiring requirements of the systems, but also to significantly increase flexibility. For our customers, this flexibility is reflected in higher system uptime. Compact drive technology with the EL72xx Servo Drives in I/O terminal format offers another advantage. They made the implementation of the numerous actuating and gripping functions in the fork and layer grippers so much easier, and in addition, new gripper concepts can be developed with low cabling effort. In the current project, PC-based control was an overall enabler for the design of the completely new Twin-Gantry robot system. The core advantage of it is that two axis systems can move independently of each other on the one hand, while on the other they can also rejoin the interpolation group at any time following an independent movement – including all key functions such as optimised path control in relation to the cycle-time. This new development also enables the use of the robots for handling of long loads.”

RO-BER relies on TwinCAT HMI software for the visualisation. Stöve adds: “As a web-based system, TwinCAT HMI makes display possible in any web browser on the most diverse platforms. Support of the HTML5 standard also makes it future-proof and open. Furthermore, TwinCAT HMI provides a complete library of functions for the optimum design and generation of customer-specific HMIs. That enables us as the machine supplier to standardise on the HMI, but still provide individualised designs for dedicated applications.” The hardware displaying the HMI is the CP2921 multi-touch Control Panel from Beckhoff. According to Stöve, the 21.5-inch operator interface makes it ideally suited to clearly display all necessary information both in text and graphic form. “On account of today’s multi-touch applications, which are familiar, for example, from smartphones, it was important to us to provide similar operator guidance functions in order to achieve higher user acceptance. The multi-touch capability, for zoom functions among other things, is very important for that. The CX2040 Embedded PC employed has also proven itself for the required CNC applications and has not approached the limits of its performance.”

The robot systems are commonly used for palletising and order picking, for storage and for connecting machines and plants. Corresponding manipulator technologies form the centrepiece of the systems. RO-BER develops and manufactures clamping, fork and vacuum grippers, among others, to handle different products in individual, multiple or layer grip mode. The areas of use are just as varied as the products themselves, including automotive, food and beverage, logistics for grocery retailers and wholesalers, and the pharmaceutical and chemical industries.

In a current intralogistics project, large load carriers such as pallet cages in different sizes and configurations that hold weights of up to 1500 kg are delivered via a conveyor system. These containers must subsequently be recognised by the robot system and transferred to tugger trains, which ultimately supply production facilities. According to Stöve, implementing the handling technology required solutions to several challenges: “Up to now, RO-BER has not had a robot that could manage such heavy loads. On top of that, the load carriers to be handled also have a large footprint, so they must be picked up from two sides. For these reasons, both the robot system and the gripping system had to be redesigned. With the robot, we took great care to ensure that modules from the existing modular system could still be used. Similar to a forklift, the new gripping system consists of a pair of fork tines that can be adjusted with respect to each other through servo control. Several CAN-networked axes are also integrated in the EtherCAT-based drive technology, which was no problem at all even with regard to the communication system. Due to the openness of PC-based control, the system was virtually plug and play.”

In total the newly developed twin-gantry robot system is comprised of five axes: a horizontal X-axis and two additional horizontal Y-axes with two vertical Z-axes. The Y/Z-axes can move both individually and within the axis group, and they can be coupled to and decoupled from the axis group dynamically.

PC-based control: the universal and open platform

Handling specialist RO-BER has been using Bus Terminal I/O from Beckhoff for many years. According to Stöve, this was a good starting point overall for the switch to PC-based control: “In 2015 we decided to replace the control and drive technology we were using at the time and to kick off corresponding market research. In 2016 we decided to go with PC-based control technology from Beckhoff, because it unites all the automation technologies we use in one system. In addition to classic PLC, our gantry robots also require CNC and safety functions. TwinCAT software provides a universal programming environment for these functions, offering a high-performance tool to make development simpler and more transparent. As we are operating our systems in intralogistics environments, seamless communication with higher-level material flow or warehouse management systems is key. Here, the open PC-based control technology from Beckhoff offers numerous advantages.”

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved