Hydraulic check valves are one of the most common valve types, and are essential components in hydraulic systems. There is potential for optimisation, particularly in applications in which screwable check valves are used in aluminium blocks.

Conventional screwed-in check valves have proved to be unreliable in some demanding applications. Situations in which the valves unscrew themselves from the housing occasionally occur. Combinations of vibration and different temperature/expansion coefficients between the valve and the holding block are the cause of weakening of the screw connection. Deformation of the hydraulic block in applications with structural loads can result in the screw connection unscrewing itself over the course of the operating time. Owing to the axially preloaded seal in the bore, even slight unscrewing results in a loss of tightness, which can have serious consequences for the hydraulic system.

Pluggable check valves

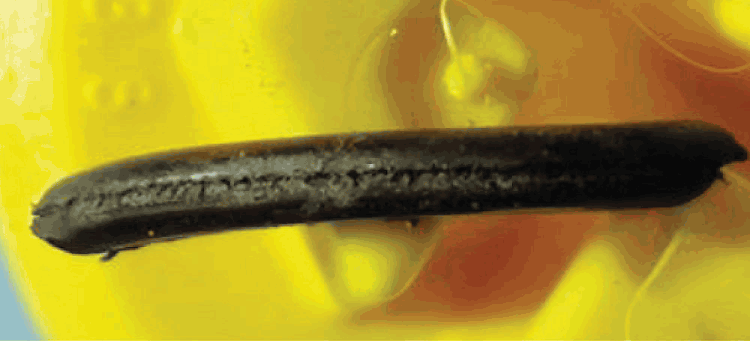

In addition to screw connections loosening, failures in connection with damaged seals can occur, particularly in O-rings with low Shore hardness that are frequently used in low-temperature applications. The complex installation location at the bottom of the bore, combined with the necessary torque for preloading of the O ring, can lead to risks. In some cases, the O-rings are cut into during mounting.

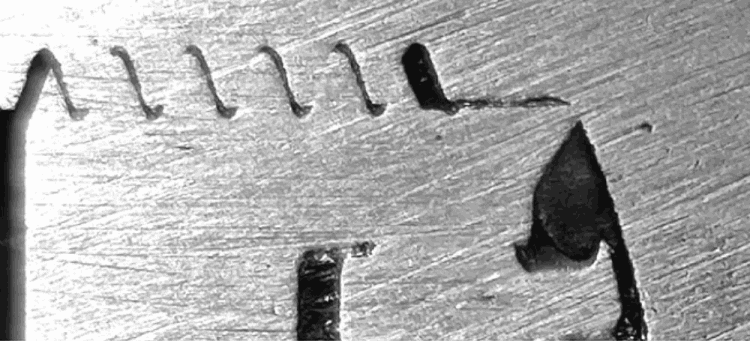

Contamination by solid matter in hydraulic oil is a common cause of hydraulic problems and machine downtime during commissioning and in operation. Wear, in the form of thread splinters in the aluminium block, is also a challenge in the use of valves with steel threads. In addition to the usual dangers to seals, valves and other system components, splinters of the thread may obstruct the non-return valve and cause the screw-in torque to be reached early, even though the required screw-in depth for the valve has not been reached. Complex flushing processes are often required during commissioning to remove splinters from the system.

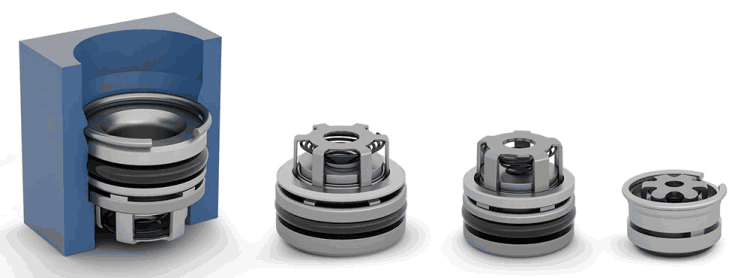

The RVH series

WEBER-HYDRAULIK has developed the new RVH valve series to mitigate these risks. These have a radial seal, and are held into the cavity bore by a round-wire snap ring. The force on the snap ring is dissipated into the material of the block at a 45° angle owing to preloading of the snap ring and the contact surface of the valve touching the ring. During burst testing in aluminium blocks, the valves withstood pressures of more than 1000 bar.

The valves in the RVH series have conical springs which are contained in a retainer. Despite the compact design, a large opening stroke is achieved, and the pressure drop that occurs is lower than in comparable valve sizes with a conventional design, allowing for energy savings for the entire system. In addition, soft springs can be used owing to the comparatively low weight of the moving parts, thus allowing for extremely low opening pressures. This is why the valves in the series are also suitable for use as suction valves. The valves are also significantly less susceptible to shock and vibration, owing to the comparably lower mass of the sealing plate.

The 100% tested valves in the RVH series are particularly suitable for use in low-temperature applications, applications with high vibrations, shock loads and structural loads, and also in energy-efficient systems.

In addition to the wide range of possible uses, the plug-in installation results in significant time savings in comparison with conventional screw-in non-return valves, particularly in low installation positions. The customer does not need a thread cut into the block, and contamination of the system is minimised owing to the screwing-in process no longer being required. The valve assembly tool indicates to the worker that the correct valve and snap ring position inside the bore are achieved during installation. An electronic connection allows for monitoring and documentation of the correct installation process, and facilitates traceability within linked installation and test procedures.

© Technews Publishing (Pty) Ltd | All Rights Reserved