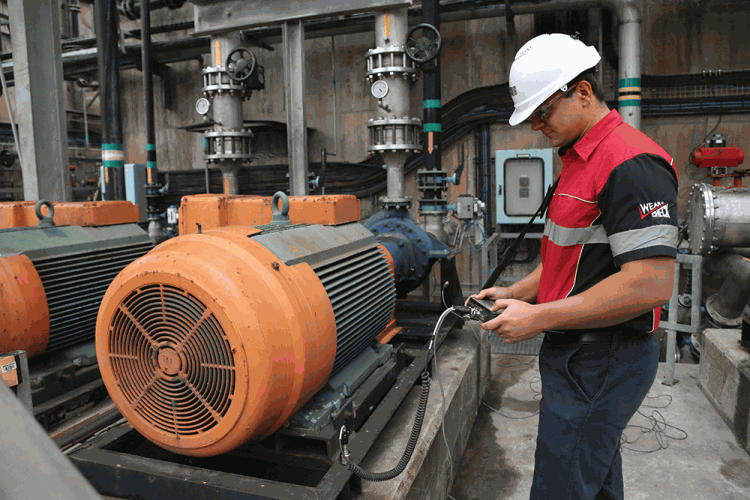

Condition monitoring specialist, WearCheck, has solidified its position as a leading player in the asset reliability care (ARC) sector. Backed by ISO accreditation, the company has served as a comprehensive reliability solutions provider for over four decades. Initially focusing on tribology and the scientific analysis of used oil samples, WearCheck constantly expands its repertoire.

ARC technologies have played a major role in the company’s service offering for over ten years, and encompass various predictive maintenance monitoring techniques to comprehensively address all aspects of asset care.

The extensive range of ARC services offered by WearCheck includes vibration analysis, thermography, online remote monitoring diagnostics, alignment and balancing. Additionally, specialised techniques like motion amplification, operational deflection shape (ODS), and resonance tests using transient and impact analysis are part of the company’s offerings. These value-added services have not only garnered loyalty from long-standing tribology customers, but have also attracted a new clientele.

Philip Schutte has led the ARC division for the past decade. He emphasises the holistic nature of WearCheck’s ARC programme, coupled with oil analysis services, which provides customers with a comprehensive view of their assets. This approach empowers maintenance teams to make informed decisions based on accurate, intelligent analysis, thereby eliminating guesswork from maintenance strategies.

Schutte highlights the innovative testing and investigative technologies employed by WearCheck, ensuring that customers’ assets surpass their projected life expectancy, while optimising plant availability. Precision maintenance services such as laser alignment, in-place balancing and gear profiling are among the measures undertaken to mitigate premature failures due to mechanical issues.

Tailored condition monitoring services for plant and mining equipment are further enhanced through the ARC division, utilising advanced methods like structural resonance analysis, transient analysis and motor current signature analysis. The team also specialises in thermal monitoring of electrical equipment and building wiring circuits.

Investing in appropriate technology is paramount for Schutte, who underscores the role of infrared monitoring in significantly reducing electrical maintenance costs by preventing catastrophic failures and unplanned downtime. He illustrates how thermography can address issues like inefficient transformer cooling systems, ultimately reducing energy consumption.

Condition monitoring, according to Schutte, plays a pivotal role in identifying malfunctions early, thus averting unnecessary maintenance costs. WearCheck’s certified technicians meticulously analyse machine data, comparing parameter trends against baselines to detect potential issues at their nascent stages.

To stay abreast of the latest techniques in asset reliability care, WearCheck ensures continuous training for its ARC team, often taking advantage of courses provided by the Mobius Institute. Additionally, WearCheck itself is an accredited Mobius course provider in Africa, enabling the firm’s highly skilled Mobius-certified technicians to champion excellence in asset reliability care, further solidifying its industry-leading position.

Regular interaction with the International WearCheck Group facilitates the exchange of insights and information on global condition monitoring techniques, enriching WearCheck’s service offerings. Besides ARC and oil analysis, WearCheck extends its expertise to transformer analysis, water analysis, lubricant-enabled reliability services and a range of advanced field services like rope testing and non-destructive testing.

In conclusion, WearCheck’s dominance in the ARC field is a testament to its commitment to excellence, innovation and continuous improvement in condition monitoring practices, ensuring optimal asset performance and reliability for its clients.

WearCheck operates an extensive network of 16 laboratories in South Africa, Namibia, Zimbabwe, Zambia, Mozambique, Ghana, DRC, Dubai and India, supported by regional offices in several other African countries. The company’s ARC services are available throughout its operational footprint.

| Tel: | +27 31 700 5460 |

| Email: | [email protected] |

| www: | www.wearcheck.co.za |

| Articles: | More information and articles about Wearcheck |

© Technews Publishing (Pty) Ltd | All Rights Reserved