The mining industry has a significant impact on the environment. In addition to the occupation of land, mines generate an ongoing demand for energy, water and other consumables. World demand for metals is on the rise. Metals such as copper, nickel and cobalt are essential components of energy storage, further putting pressure on the market. As the world works towards a temperature reduction target of 1,5°C, the mining industry will need to more than double the supply of copper and quadruple the supply of nickel over the next 30 years.

Meanwhile, mining and processing industries continue to emit huge volumes of greenhouse gases into the atmosphere.

A significant amount of the energy consumed in ore processing can be attributed to the comminution process, which accounts for 30 to 35% of the overall energy required. The most common comminution circuits combine semi-autogenous grinding and ball milling. It is estimated that world electricity consumption for autogenous grinding ball mill circuits is 116,5 TWh annually. Grinding balls also contribute to an additional 14,95 million tons of waste.

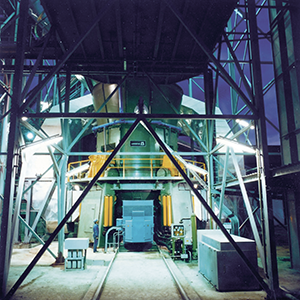

Conventional comminution technologies are proven and reliable, but offer little process flexibility. However there is a less energy-intensive and more sustainable solution – complete dry processing. This is possible with LOESCHE’s vertical roller mills.

The world’s largest ore market is the iron ore industry. Here the dry grinding process in LOESCHE mills enables pre-separation of dry magnetite into coarse iron ore fractions, with a gangue rejection of 20 to 40% by mass. Significant savings in water, energy, and grinding media can be achieved. Tailings dams can be reduced in size, and potential environmental and social hazards minimised. Ongoing improvements and new developments in fine dry magnetic separation technologies are further increasing the percentage of iron ore that can be treated when completely dry.

LOESCHE vertical roller mills also offer state-of-the-art grinding technology for the cement, steel, power and minerals industries. These mills have proved themselves through reduced operating expenses. This is achieved through decreased energy, water, and grinding media costs, advanced process flexibility, consistently high product quality, reduced process steps, online process control, high reliability, and easy maintenance.

Energy and water savings

It is possible to make savings of up to 30% in energy and 2 to 5% in water consumption for base and precious metals processing, and up to 40% in energy for iron ore processing.

Increased metal output

Grinding the ore in a grinding bed between the grinding rollers and the grinding table results in more efficient preparation of minerals for the downstream sorting process. Hence, the recovery of valuable minerals increases, and more metal can be produced from the same amount of run-of-mine ore.

Operable with renewable energy

The LOESCHE dry grinding process can be powered with renewable energy. The grinding circuit capacity can be adjusted to the available energy, whether sun or wind power. The process can be stopped and restarted within minutes if required, providing significantly greater flexibility in comparison to wet grinding circuits.

Process flexibility

Dry-ground ore can be stored in silos equivalent to power accumulators. When excess renewable energy is available, the mill capacity can be fully utilised to fill the silos. If less energy is available, pre-ground product stored in the silos can compensate for the lower throughput of the grinding circuit.

Reduced consumables and CO2 footprint

Through the use of LOESCHE’s PRONAMIC spare and wear parts, a potential material saving of 90% is possible compared to convential alternatives such as forged steel balls from SAG and ball mills.

| Tel: | +27 11 482 2940 |

| Email: | [email protected] |

| www: | www.loesche.com |

| Articles: | More information and articles about Loesche South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved