When it comes to controlling the temperature of heat sources, the ideal solution for many customer applications is temperature-controlled circulating fluid from a chiller. Maintaining a fixed temperature can improve the quality, reliability and service life of devices and equipment, and SMC boasts a lineup of solutions that caters to a broad base of requirements, including applications such as:

• Laser machining and UV curing (printing, painting, bonding and sealing).

• X-ray instruments, electron microscopes and ultrasonic wave inspection machines.

• Laser markers, atomising devices (food and cosmetics), linear motors and packaging lines (sealing of film and paper package),

shrink-fitting machines.

• Temperature control of paint material, cooling of vacuum pumps, gas cylinder cabinets, concentrating equipment, reagent cooling equipment and cleaning tanks.

• Physical and chemical equipment, arc-welding and resistance (spot) welding machines, electric furnaces.

• Laser oscillators, laser power sensors, transmission cable connectors for fibre lasers.

There’s cooling, and then there’s cooling

Just as no two applications are identical, so too there is a variety of methods, and associated technologies to achieve the cooling required. For example, when:

• There is no cooling tower and tap water is being used, an air-cooled refrigerated chiller can be used to supply cooling water, and water bills can be lowered.

• There is a cooling tower, but high temperatures in summer or low (freezing) temperatures in winter make cooling water temperatures unstable, cooling water at a consistent temperature can be supplied, regardless of the season.

• Using equipment in a small room like a laboratory or study room, compact types can be installed on or under a desk, which are compatible with physical and chemical/analytical equipment.

The fundamental mechanisms through which cooling is achieved depends on the type of cooling equipment employed, which in turn is dictated by the application’s requirements.

Peltier-type thermo-con and thermoelectric bath

For high-precision temperature control with temperature stability of ±0,01°C to 0,03°C, a Peltier-type thermo-con (Figure 1) generates little vibration, and is refrigerant-free and environmentally friendly. It can control the temperature directly in front of the heat source using an external temperature sensor.

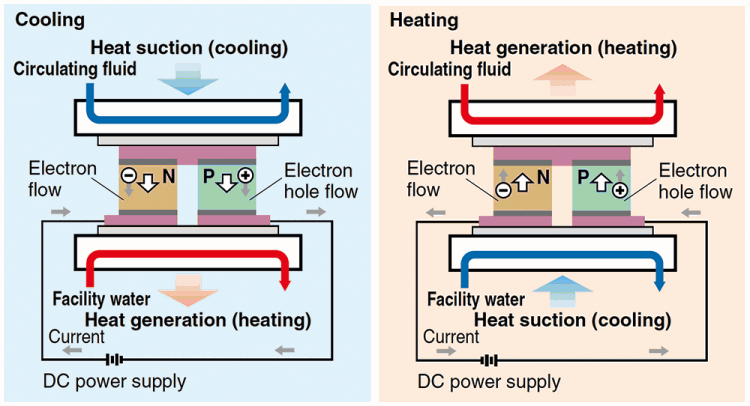

A Peltier device is a plate-type element, inside which P-type semiconductors and N-type semiconductors are layered alternately. Therefore, changing the direction of the current supplied to the Peltier device can achieve heating and cooling operation. Temperature can be controlled precisely because this method has a fast response and can switch quickly from heating to cooling.

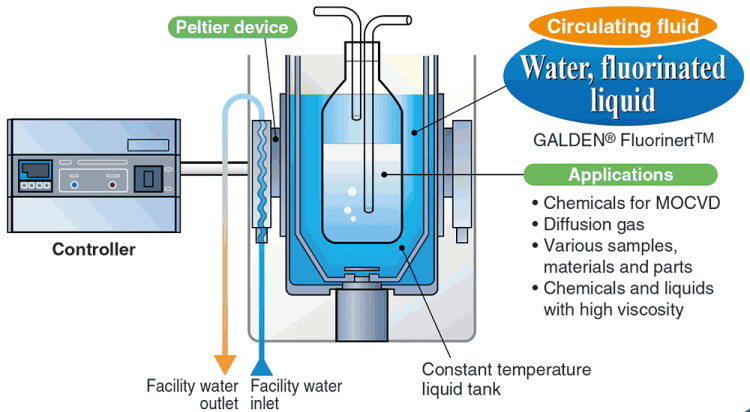

A Peltier-type thermoelectric bath, on the other hand (Figure 2), accurately controls the temperature of liquid inside it, with stability comparable to thermo-cons. Customers can control the temperature by placing a container in the tank.

Thermo-chiller (circulating fluid temperature controller)

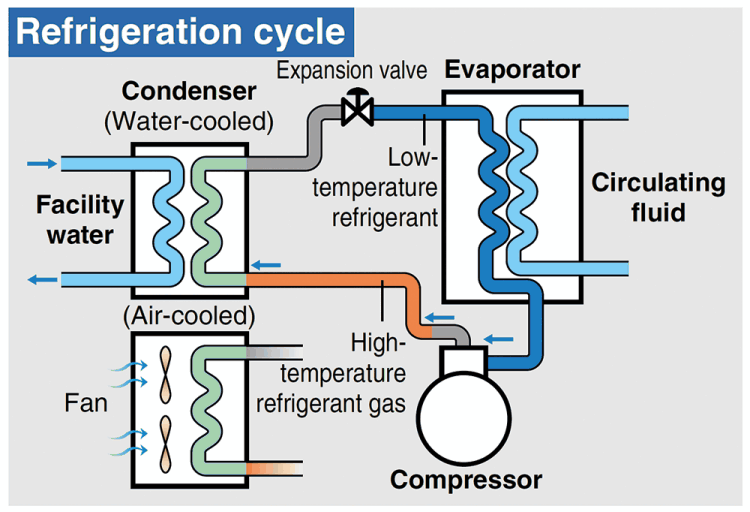

For cooling capacity from 1 to 15 kW, and covering a wide range of applications, a refrigerated thermo-chiller (Figure 3) generates low temperatures using a refrigeration cycle. This equipment cools the circulating fluid through heat exchange with low-temperature refrigerant gas, using a built-in refrigeration circuit.

Large-scale heat exchange can be handled compared with the Peltier type. There are two types of heating sources: high-temperature refrigerant gas, which is generated from the refrigeration circuit, and an electric heater. Both air-cooled and water-cooled types are available, depending on the condenser’s cooling method.

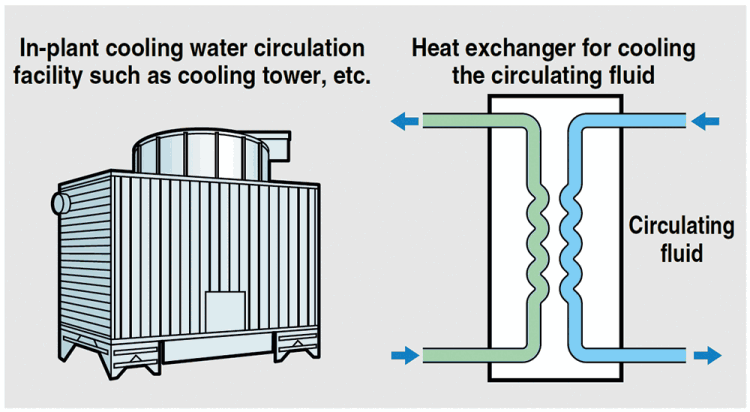

For temperature control of a room-sized area, a water-cooled thermo-chiller (Figure 4) can cover a temperature range from 20°C to 90°C. Since it does not use a compressor, this represents a refrigerant-free and energy-saving option.

This equipment cools the circulating fluid by directly exchanging it with the cooling water in the plant. This can be used at room temperature or higher, and also when there is a cooling water circulation facility. Large-scale heat exchange can be performed using less energy, and the device has a compact body since a compressor is not required. An electric heater is used for heating.

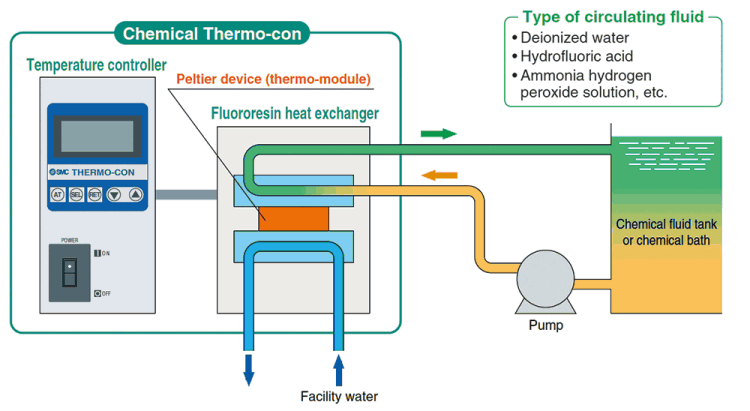

Temperature control for chemical liquids

This type of controller (Figure 5) consists of a CPU and DC power supply to energise the Peltier elements and outputs the appropriate power to these elements based on the differential between the setpoint and the reading from a temperature sensor installed in the heat exchanger. A leakage sensor is also integrated to detect unexpected water or chemical leakage.

Plenty of options to keep your cool

SMC’s comprehensive portfolio of temperature control equipment comprises models using the principles described above, and more. Table 1 provides a broad overview of the product lines on offer, and their associated temperature ranges.

© Technews Publishing (Pty) Ltd | All Rights Reserved